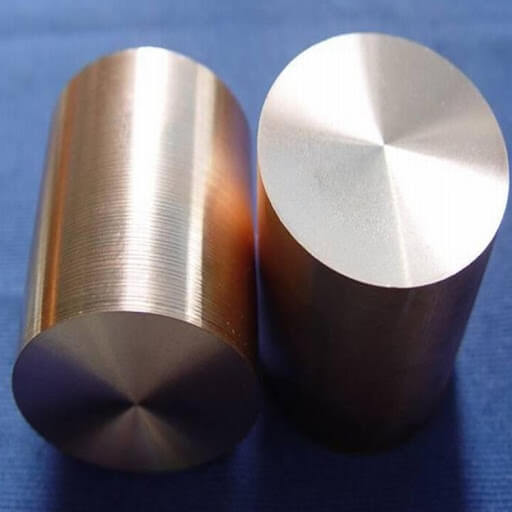

Cupronickel Series

Cupronickel or copper-nickel (CuNi) is an alloy of copper that contains nickel and strengthening elements, such as iron and manganese. The copper content typically varies from 60 to 90 percent. (Monel is a nickel-copper alloy that contains a minimum of 52 percent nickel.) Despite its high copper content, cupronickel is silver in colour. Cupronickel is highly resistant to corrosion by salt water, and is therefore used for piping, heat exchangers and condensers in seawater systems, as well as for marine hardware. It is sometimes used for the propellers, propeller shafts, and hulls of high-quality boats. Other uses include military equipment and chemical, petrochemical, and electrical industries.

Email: info@cjmetals.com.cn

Tel: 0086-021-57629806

| Grade list of copper and copper alloys by country | |||||||

| Classification | China | Germany | America | Japan | England | Europe | International |

| oxygen free copper | TU1 | 2.0076 | C10200 | C1020R | C103 | ||

| TU2 | Cu-OF-H110 | C11000 | c1011 | C101 | |||

| Vacuum oxygen free copper | E-Cu58 | TU00 | c1020 | 6N | |||

| high purity | copper-OFE | c10500 | c10700 | ||||

| Silver copper | TAg 0.1 | CuAg 0.1 | C10400 | C1040 | CuAg 0.1 | ||

| brass | H90 | CuZn10 | C22000 | C2200 | CZ101 | CuZn10 | CW501L |

| H70 | CuZn30 | C26000 | C2600 | CZ106 | CuZn30 | CW505L | |

| H68 | C26200 | C2620 | CuZn33 | CW506L | |||

| H65 | CuZn35 | C27000 | C2700 | CZ107 | CuZn36 | CW507L | |

| H63 | CuZn37 | C27200 | C2720 | CZ108 | CuZn37 | CW508L | |

| H62 | CuZn40 | C28000 | C2800 | CZ109 | CW509L | ||

| bronze | QSn4-0.3 | CuSn4 | C51100 | C5111 | PB101 | CuSn4 | CW450K |

| CuSn5 | C51000 | C5101 | CuSn5 | CW451K | |||

| QSn6.5-0.1 | CuSn6 | C51900 | C5191 | PB103 | CuSn6 | CW452K | |

| QSn8-0.3 | CuSn8 | C52100 | C5210 | CuSn8 | CW453K | ||

| QSn6.5-0.4 | |||||||

| copper-nickel | BZn18-18 | CuNi18Zn20 | C75200 | C7521 | NS106 | CuNi18Zn20 | |

| BZn18-26 | CuNi18Zn27 | C77000 | C7701 | NS107 | CuNi18Zn27 | CW410J | |

| BZn15-20 | C7541 | CW409J | |||||

| BZn18-10 | C7350 | ||||||

| pure copper | TU2 | OF-Cu58 | C10100 | C1011 | C101 | CW008A | copper oxide |

| T2 | SW——copper | C11000 | C1100 | C101 | copper - FRHC | ||

| TP2 | SF-Cu | C12200 | C1220 | C106 | CW024A | copper - DHP | |

| TP1 | SW-copper | C12000 | C1201 | CW023A | copper DLP | ||

| Alloy | Density g/cm3 | Thermal conductivity W/(m·K) | TEC μm/(m·K) | Electrical resistivity μOhm·mm | Elastic modulus GPa | Yield strength MPa | Tensile strength MPa |

|---|---|---|---|---|---|---|---|

| 90–10 | 8.9 | 40 | 17 | 19 | 135 | 105 | 275 |

| 70–30 | 8.95 | 29 | 16 | 34 | 152 | 125 | 360 |

| 66–30–2–2 | 8.86 | 25 | 15.5 | 50 | 156 | 170 | 435 |

Properties of some Cu–Ni alloys

| Alloy UNS No. | Common name | European spec | Ni | Fe | Mn | Cu |

|---|---|---|---|---|---|---|

| C70600 | 90–10 | CuNi10Fe | 9–11 | 1–1.8 | 1 | Balance |

| C71500 | 70–30 | CuNi30Fe | 29–33 | 0.4–1.0 | 1 | Balance |

| C71640 | 66–30–2–2 | 29–32 | 1.7–2.3 | 1.5–2.5 | Balance |

UNS standard compositions* of wrought alloys (in at%). Maximum or range.

Marine engineering

Cupronickel alloys are used for marine applications due to their resistance to seawater corrosion, good fabricability, and their effectiveness in lowering macrofouling levels. Alloys ranging in composition from 90% Cu–10% Ni to 70% Cu–30% Ni are commonly specified in heat exchanger or condenser tubes in a wide variety of marine applications.

Coinage

The successful use of cupronickel in coinage is due to its corrosion resistance, electrical conductivity, durability, malleability, low allergy risk, ease of stamping, antimicrobial properties and recyclability.

Other usage

Single-core thermocouple cables use a single conductor pair of thermocouple conductors such as iron-constantan, copper constantan or nickel-chromium/nickel-aluminium. These have the heating element of constantan or nickel-chromium alloy within a sheath of copper, cupronickel or stainless steel.

Cupronickel is used in cryogenic applications. Its combination of good ductility retention and thermal conductivity at very low temperatures is advantageous for low-temperature processing and storage equipment as well as for heat exchangers at cryogenic plants.

For high-quality cylinder locks and locking systems, cylinder cores are made from wear-resistant cupronickel.