What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

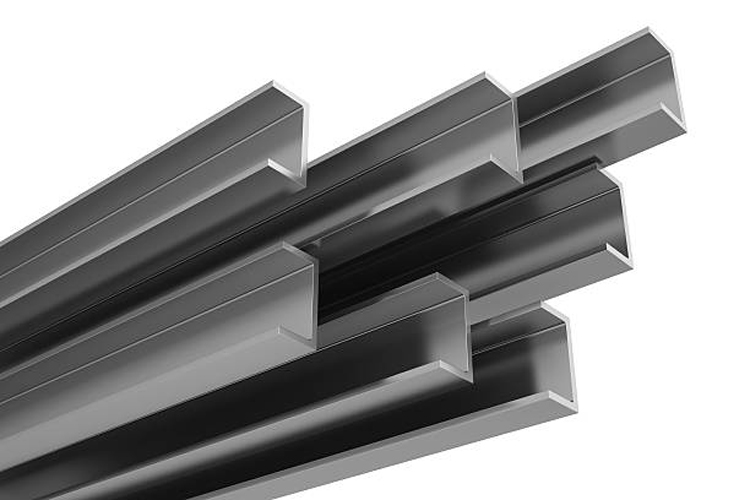

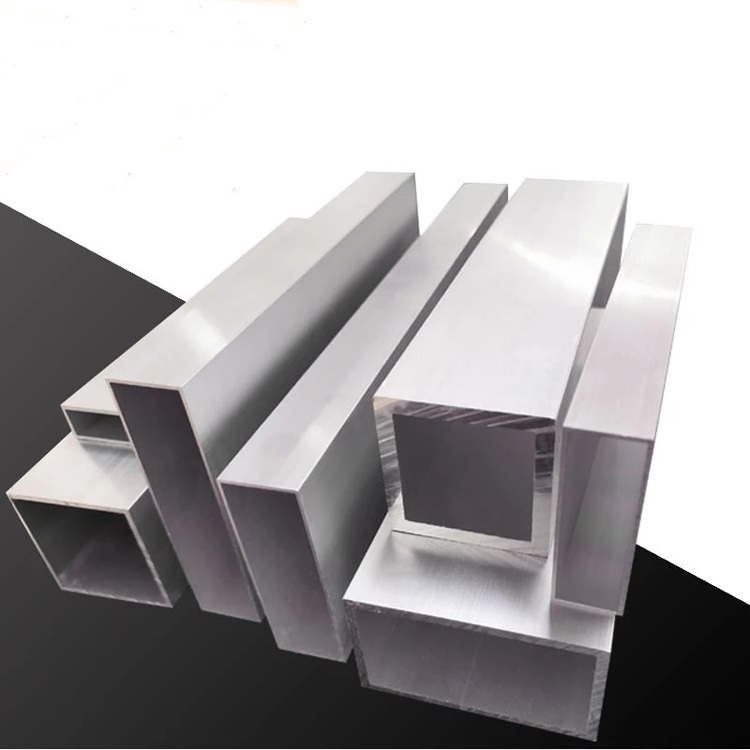

What is the difference between 201 st...Aluminum alloy profiles are a kind of non-ferrous metal structural materials widely used in the industry, in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, construction and decoration. And the chemical industry has been widely used. With the rapid development of science and technology and industrial economy in recent years, the demand for aluminum alloy welded structural parts is increasing, and the research on the weldability of aluminum alloy profiles has also deepened. The wide application of aluminum alloy has promoted the development of aluminum alloy welding technology, and the development of welding technology has expanded the application field of aluminum alloy. Therefore, the welding technology of aluminum alloy is becoming one of the research hotspots.

The density of pure aluminum is small (ρ=2.7g/cm3), about 1/3 of that of iron, and the melting point is low (660℃). ψ: 70~90%), easy to process, can be made into various profiles and plates, and has good corrosion resistance; but the strength of pure aluminum is very low, and the σb value of the annealed state is about 8kgf/mm2, so it is not suitable for structural materials. Through long-term production practice and scientific experiments, people gradually strengthen aluminum by adding alloying elements and applying heat treatment, which has a series of aluminum alloys. The alloys formed by adding certain elements can maintain high strength while maintaining the advantages of pure aluminum and light weight, and the σb values can reach 24-60kgf/mm2 respectively. This makes its "specific strength" (ratio of strength to specific gravity σb/ρ) better than many alloy steels, making it an ideal structural material, widely used in machinery manufacturing, transportation machinery, power machinery and aviation industry, etc. , skin, compressor, etc. are often made of aluminum alloy profiles to reduce self-weight. Using aluminum alloy to replace the welding of steel plate material, the structural weight can be reduced by more than 50%.

The aluminum alloy profile is the product of the 20th century and has been fully developed and widely used in the 21st century. It has now become an indispensable material in production and life.

(1)Industrial aluminum profiles, general industrial aluminum profiles refer to: mainly used in industrial production, such as automated mechanical equipment, enveloped skeletons, and companies to customize molding according to their own mechanical equipment, such as pipeline conveyance belts, improve Machine, dispensing machine, testing equipment, shelves, etc., electronic machinery industry and clean rooms;

(2)building aluminum profiles, architectural aluminum profiles mainly include doors and windows aluminum profiles and curtain wall aluminum profiles;

(3)radiator aluminum profile, mainly used in all kinds of power electronics heat dissipation, LED lighting lights, and heat dissipation of computer digital products;

(4)car parts aluminum profile, mainly used in automotive parts, connectors, etc;

(5) furniture aluminum profiles, mainly used in furniture decoration boxes, table and chair support, etc;

(6)solar photovoltaic profiles, solar aluminum profiles, solar photovoltaic brackets, solar photovoltaic fasteners, etc;

(7)the rail vehicle structure aluminum alloy profile is mainly used for the manufacture of rail vehicles. The aluminum alloy profile has the characteristics of light mass, good shape, high strength, corrosion resistance, recovery, and aluminum and aluminum alloys in the field of rail vehicles in recent years;

(8)decorate aluminum profiles, making it into aluminum alloy, decorated various exhibitions, decorative paintings;

(9)Medical equipment aluminum profiles, mainly used in the stretcher frame, medical equipment, medical bed, etc.

(1) Pixabay

Point corrosion is also known as pore corrosion, is a very local corrosive morphology that produces a needle, point-shaped, and apertured on the metal. Aluminum in the atmosphere, freshwater, or the neutral aqueous solution, can also cause perforation, but the corrosion hole may ultimately stop development, and the corrosion maintains a limit value. Point corrosion is a unique form of an anode reaction is a self-catalytic process.

(2) Corrosion

Corrosion is also the characteristic corrosive morphology of aluminum, and the natural potential of aluminum is very negative. When the aluminum is in contact with other metals, aluminum is always in an anode to accelerate it. Electrocouple corrosion is also called bimetallic corrosion, and the severity of its corrosion is determined by opposite positions in two metal potentials.

(3) Gap corrosion

Corrosion is due to difference inflatable batteries, resulting in acceleration of corrosion within the gap, while there is no effect outside the gap. The gap corrosion and the type of alloy are not large, even very resistant alloys produce gap corrosion. In recent years, there has been a more in-depth study for the mechanism of gap corrosion, and the acidic environment of the gap is corroded.

(4) Crystal corrosion

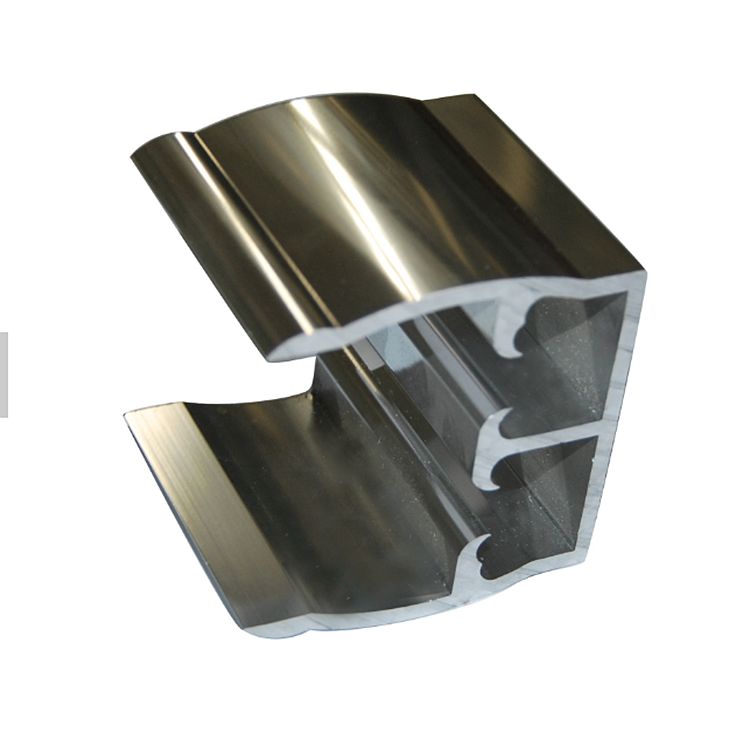

Inter-crystal corrosion refers to pure aluminum is not in full swing, and the cause of transistor is not accurate with heat treatment. The alloying element or intermetallic compound is precipitated along the grain boundary, and the anode constitutes a corrosion battery relative to the grain, causing a crystal Corrosion acceleration.Structural aluminum profile isolated on a white background.

(5) Silk corrosion

Mitor corrosion is corroded under a membrane, which is developed under the membrane, which can make the paint film, or other layers, generally do not occur under the anodized film.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...