What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...In recent years, aluminum tube is widely used in all walks of life, and now more, more industries use aluminum tubes to replace other metal tubes. So what is the advantage of aluminum tube? What are the applications in which industries apply?

Aluminum tube refers to a metal tubular material that is processed by pure aluminum or aluminum alloy. There may be one or more closed through holes, wall thickness, uniform cross section, linear or roll-on delivery.

Classification of aluminum tubes:

1.According to the shape: square tube, round tube, pattern tube, exotic pipe;

2.According to the extrusion method: seamless aluminum tube and ordinary extrusion tube;

3.According to the precision: ordinary aluminum tube and precision aluminum tube, wherein the precision aluminum tube generally needs to process again, such as cold pulling, rolling;

4.Press thickness: ordinary aluminum tube and thin wall aluminum tube;

Advantages of aluminum tube:

1. Strong toughness: effectively safeguard the plasticity of the connection material;

2. High corrosion resistance: Ensure that the use of aluminum tube processing products is long, and the price is better;

3. Heavy thermal conductivity: Aluminum tube itself has strong thermal conductivity, which can achieve performance consistent with other processing materials;

Disadvantages of aluminum tube:

1.Heating is easy to deform: generally aluminum tube is heated to a certain extent. To this end, you need to select the best license of aluminum tube according to your own product performance and aluminum pipe use;

2.The price cost is higher: the price cost of aluminum tube may be greater than other metal tubes, and the weight of the aluminum tube is light in other metal tubes;

In general, when choosing the most practical pipe material for your product, it is mainly necessary to consider the use environment, processing performance, etc., such as: whether it needs to be bent, whether it needs to be anti-corrosion, etc.

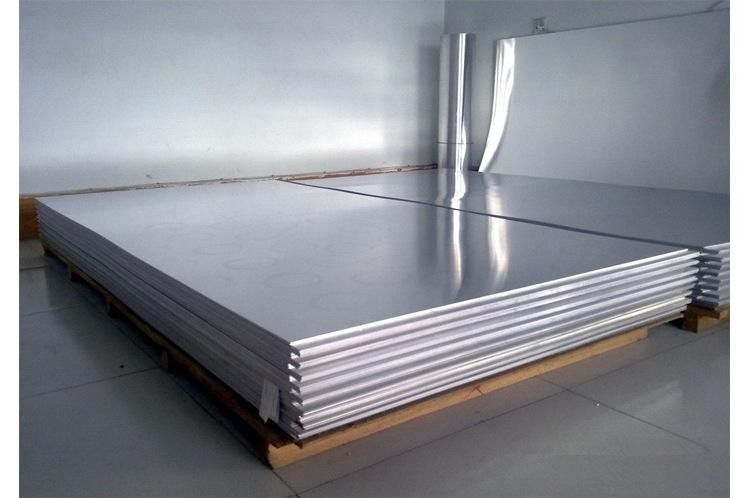

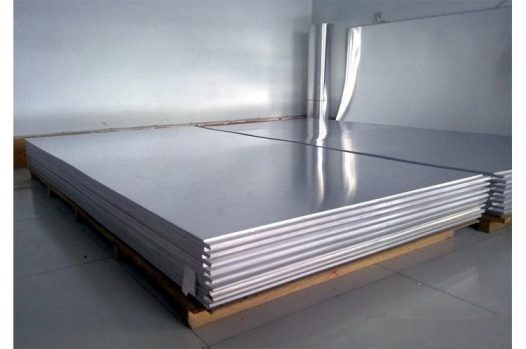

Aluminium sheets are widely used in industries:

First: the container industry

Aluminum plates for containers are mainly used in navigation, and there are requirements for the hardness of aluminum plates. 3 series aluminum plates and 5 series aluminum materials are more commonly used in the container industry. Since China joined the WTO, it has gradually played an increasingly important role in the world economy.

As a result, the import and export volume has increased year by year, and the amount of containers in China has increased sharply, bringing another new opportunity for the aluminum industry.

Second: Aerospace

The aluminum plates used in the aerospace industry are all made of high-end aluminum materials, which have very strict production process requirements. Therefore, 7-series aluminum materials are often used in aerospace, such as China's aircraft manufacturing, Shenzhou spacecraft series, satellites, etc. Aircraft, spaceships and other aviation machines have high requirements on the hardness of the material, and the density of the material should not be too large. The 7 series aluminum plate can meet these requirements.

Third: canned beverage bottles

In the past few decades, the beverage market has developed rapidly, and canned beverages have ushered in the spring. Canned beverage bottles are mainly made of 5-series aluminum, especially 5182 aluminum. upscale aluminum, and strict requirements in terms of production process.

Shanghai Changjin Metal Product Co.,Ltd. is committed to becoming a technological pioneer in the field of metal raw materials through technological innovation, and strives to produce zero-defect, high-precision products with high degree and superior performance.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...