What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...Aluminum alloys have been used in the shipbuilding industry for nearly a hundred years. With the rapid development of the shipbuilding industry at home and abroad, the lightweight of ships has been paid more and more attention. Due to the low density, high strength, high rigidity and corrosion resistance of aluminum (aluminum and The density of aluminum alloy is low, about 1/3 of steel, and it has strong corrosion resistance to seawater), so the application effect of aluminum alloy for ships on ships is very significant.

Aluminum for ships has the characteristics of small specific gravity and elastic modulus, corrosion resistance, weldability, easy processing, non-magnetic and good low temperature performance. It has the following advantages when used in ships:

(1) Due to its small specific gravity, it can reduce the weight of the ship, reduce the single engine capacity, and increase the speed; it can reduce fuel consumption and save fuel; it can improve the aspect ratio of the ship, increase the stability, and make the ship easy to maneuver.

(2) Due to its good corrosion resistance, it can reduce maintenance costs such as oiling, and can extend the service life.

(3) Good processing and forming performance, easy to carry out various forms of processing such as cutting, stamping, cold bending, forming and cutting, suitable for streamlining the hull; It can extrude large wide and thin-walled profiles, reducing the number of welds and Rationalize and lighten the hull structure.

(4) The welding performance is good, and it can be easily welded.

(5) The elastic modulus is small, the ability to absorb impact stress is large, and the safety is greater.

(6) Aluminum waste is easy to recycle and can be recycled.

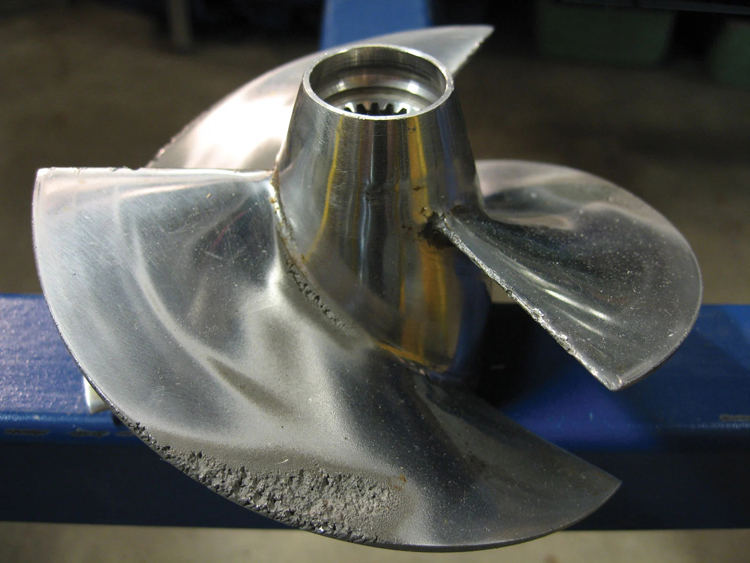

The high toughness, corrosion resistance and weldability of aluminum alloys provide a good choice for the construction of ship types with strict weight requirements. Due to the lower processing cost of aluminum, it is more economical to use aluminum to build ships. Aluminum alloy can be used as a sheet, and can also be processed by extrusion and casting.

From the point of view of ship designers, ships made of aluminum for ships can achieve higher speed and longer service life. These advantages of aluminum alloys make it develop rapidly in the application of ships. The shipbuilding industry is a Aluminum provides a broad application market.

About the causes and treatment of light color and color difference of aluminum materials:

(1) The thickness of the oxide film is uneven. The possible reason is that the temperature and concentration of the anodizing bath liquid are uneven. At this time, the bath liquid should be stirred with compressed air to solve such problems.

(2) The temperature or concentration of the dye solution is uneven. Introduce a stirring process and increase the number of stirrings at the same time.

(3) The dyeing speed is too fast. The bottom of the workpiece enters the dye solution first and then leaves the dye solution, so the bottom is easy to dye deeply. The solution is to dilute the dye and prolong the dyeing time appropriately.

(4) Poor electrical conductivity. It may be caused by the loose hanger, pay attention to hang it tightly to avoid such problems.

(5) If the dye is too dilute, add dye to increase the concentration.

(6) The temperature of the dye solution is too low. The dye liquor can be heated to below 60℃.

(7) Improper dissolving of dyes, or floating of insoluble dyes, chromatic aberration is easy to occur at this time. The solution is to improve dye dissolution.

In order to decorate and improve the surface properties of aluminum materials, coloring treatment is carried out on the oxide film of aluminum materials. Commonly used methods include electrolytic coloring, chemical coloring, and natural coloring.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...