What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...Aluminum materials are articles made from aluminum and other alloy elements, usually processed into castings, forged products, and foil, plates, tubes, tubes, rods, profiles, etc., and then pass through cold bend, sawing, drilling, assembly , Made into steps such as colors, aluminum profiles are widely used in construction, industrial production, automotive manufacturing, furniture manufacturing, medical equipment manufacturing and other fields. There are many kinds of aluminum alloy profiles, and there are commonly used pure aluminum alloys, aluminum copper alloys, aluminum magnesium alloys, aluminum magnesium alloys, and different types of aluminum alloy profiles.

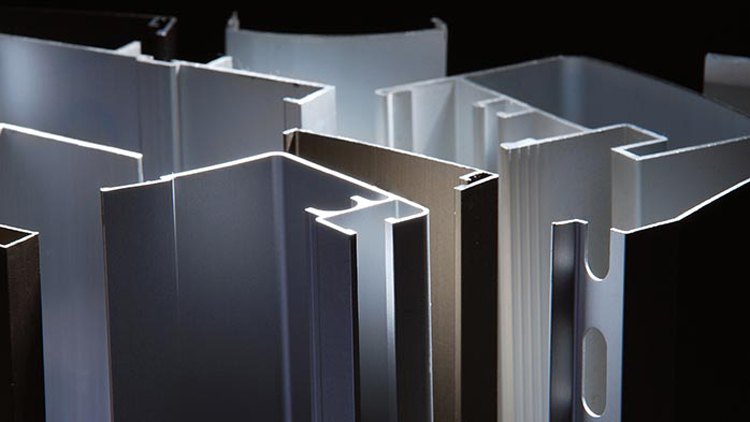

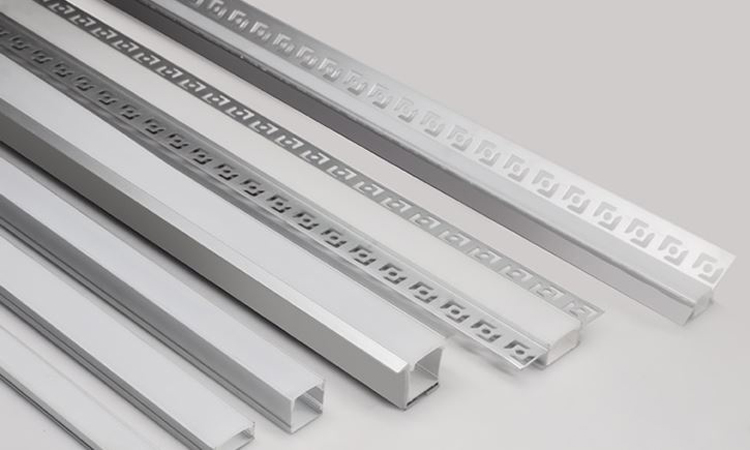

Aluminum profiles are one of aluminum products, and there are many fine classifications of aluminum profile products.

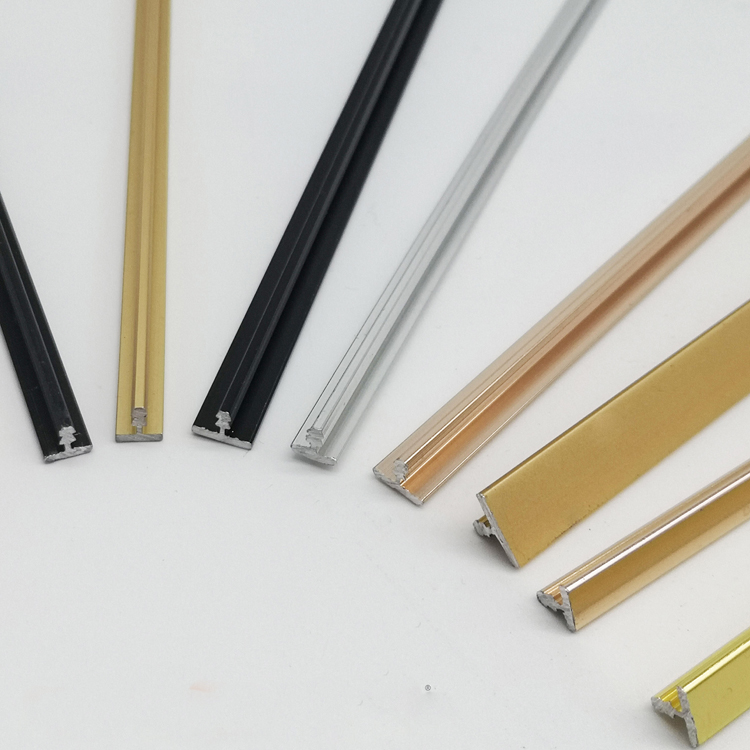

Border aluminum profiles are more, like solar bodes, light box borders, electrical borders, etc., especially the solar border has been very large in recent years.

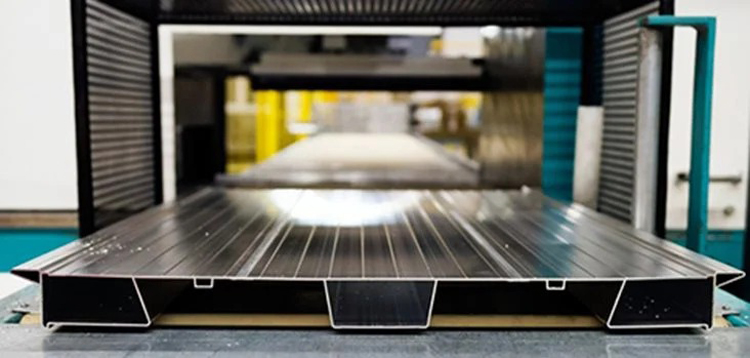

Beam aluminum products are used on some relatively large mechanical equipment, such as printer beams, engraving machine beams, aluminum alloy keel. This aluminum profile product is generally relatively large and heavy.

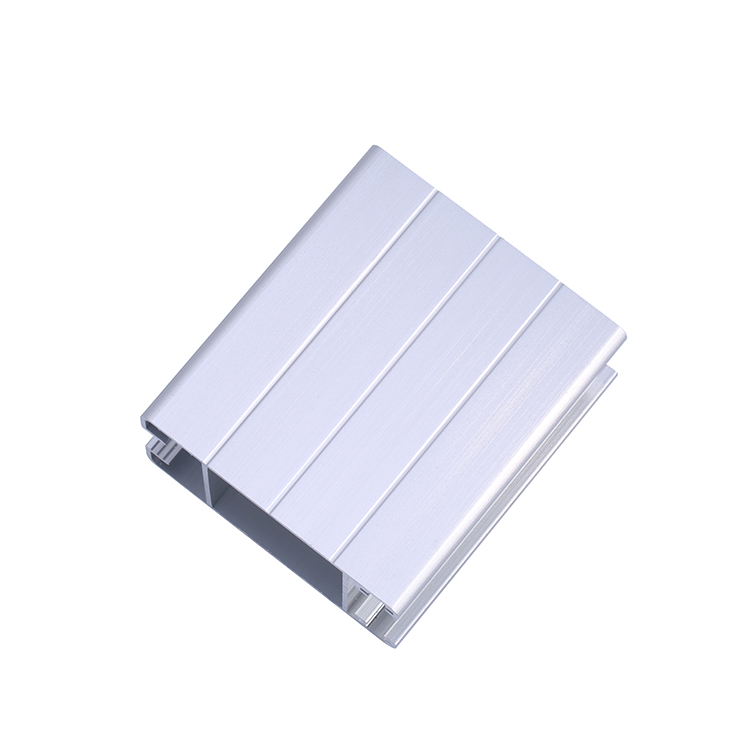

The panel aluminum profile can be used as a base panel of the LED lamp, a power amplifier sound panel, a radiator panel, and the like, and it is also very wide.

There is a variety of parts of the aluminum profiles, some frame connectors, brackets, angles, etc. Result.

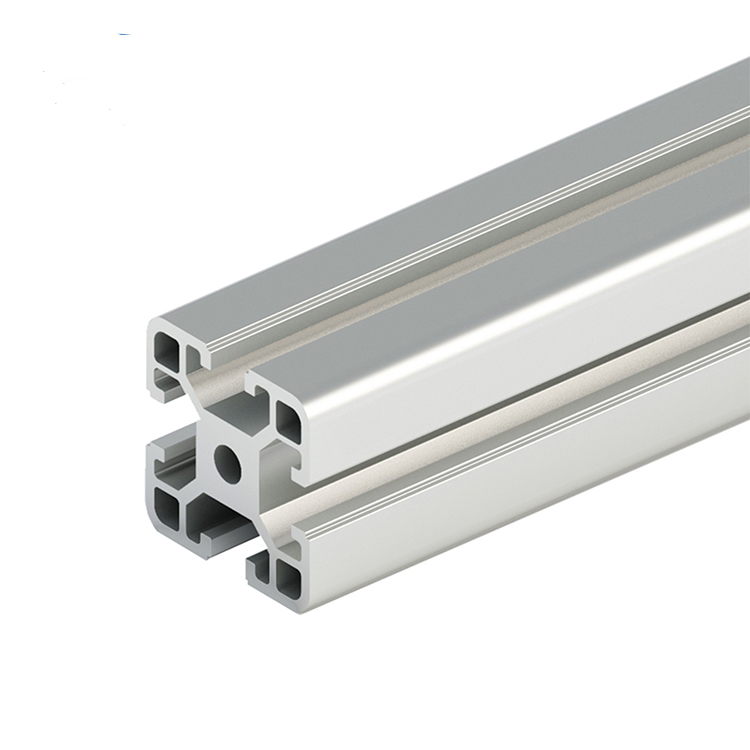

Aluminum profiles are generally large, like pipeline workbenses, materials racks, maintenance platforms, dust-free rooms, etc., all of which are aluminum profile frameworks. The aluminum profile of the fabrication of the frame is a industrial aluminum profile that is like a square tube.

One is the model of aluminum profile according to the design drawings. If the desired aluminum model is not indicated on the design drawings, you can consult the aluminum profile manufacturer, depending on the load carrying capacity of the desired product, it can bear Price ranges and use environments, use space-to-range, to select a most cost-effective industrial aluminum profile model.

Aluminum profiles are required to pass a professional workflow. First, according to the aluminum alloy card requirements, the aluminum all-made materials are required, and then mixed the raw materials, the aluminum solutions can be cooled, and then squeezed. Pressure, oxidation, and sealing and other work steps.

Aluminum profiles are generally required to have a professional aluminum cutting machine to complete, or may cause harsh roughness and size. First, the lubricating oil is applied to the tool or aluminum profile, and then the machine is cut directly. If you need to cut a special angle, you can use the CNC machine tool to cut.

Various products made from industrial aluminum profiles are called industrial aluminum profiles, such as aluminum profiles, belt conveyors, industrial protective fences, dust-free rooms, equipment shields, aluminum profiles, aluminum profiles, etc. They are all industrial aluminum profiles. Since industrial aluminum profiles themselves are light, environmentally friendly, corrosion, easy to clean, and long service life. However, in some cases are improper use, and it will also have a certain effect on the service life of aluminum profiles.

1) The structural strength is not enough, and the industrial aluminum profile has thick and thin, and there is a small section. Aluminum profile products with large load strength are produced if a thin profile of a small section is used. That life is a big discount. This is like letting a thin child do an adult physical activity, sooner or later is going to be tired. Therefore, industrial aluminum profiles that choose suitable intensity are very important as raw materials.

2) The design is unreasonable, and the design of an aluminum profile product is very important. It is necessary to consider the use of people to use, and consider even the load is even. If the strategy is a lightweight material, it is half-sized, which is a hard-sized material.

3) Improper use of aluminum profiles, industrial aluminum profile products are mainly based on aluminum profiles, and there is no provision of accessories. The place where the powerful corner is absolutely cannot use ordinary corners.

4) The quality of other parts must be guaranteed, such as the desktop of the workbench, now usually use anti-static table, the countertop must not only have anti-static function, but also wear resistant, easy to clean. The aluminum profile frame is not bad, and the countertop is broken and it is very troublesome.

1) When the surface of the aluminum profile is eroded and contaminated, it is necessary to clean it in a timely, and the fouling can be wound with alcohol or fragrance water, then washed with water;

2) Cleaning should be used with warm water containing lubricants or neutral cleaning agents, which is not allowed to use acidic or alkaline cleaning agents;

3) The scrubbing appliance is suitable for the soft cloth, the towel is suitable, and it is strictly forbidden to use the surface of the aluminum profile of the briquette, sandpaper, wire brush or other friction;

4) Aluminum alloy profiles after cleaning, preferably use high quality topcoat to protect the anodizing film to perform light treatment, or uniformly spray a layer of acrylate cleales;

5) According to the environment where the use is used, the aluminum alloy profiles should be regularly cleaned with pollutants and maintain light brightness.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...