What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...

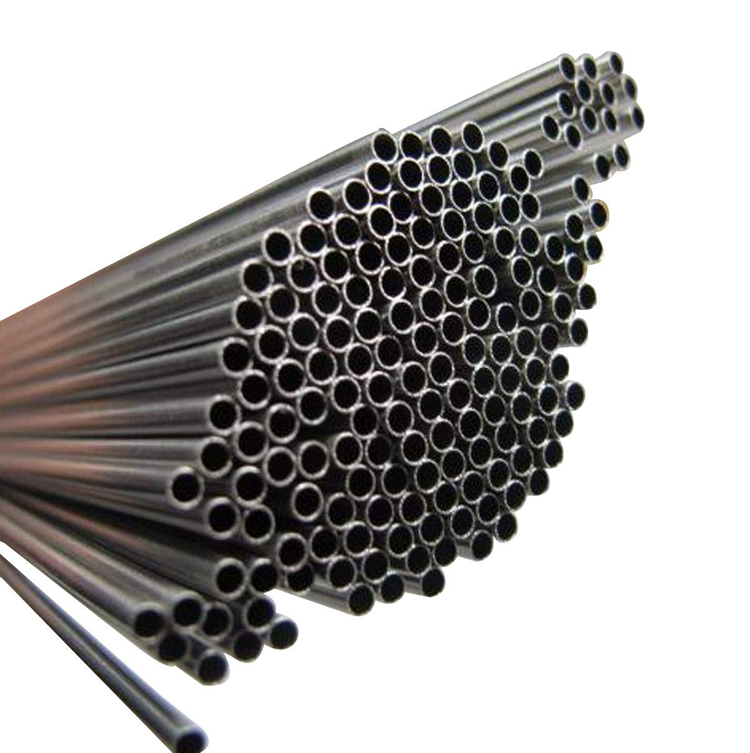

Capillary Characteristics: Good flexibility, corrosion resistance, high temperature, wear resistance, tensile, waterproof, and provide excellent electromagnetic shielding properties. Stainless steel hoses are freely bent into a variety of angles and curvature radii, and all the same flexibility and durability in each direction; the stainless steel hose pitch is flexible, there is better scalability, no blocking and stiff phenomenon The stainless steel threading hose has a certain tensile force between the buckles of the hose, which causes the hub to expose the line laid in the hose, and the axial tension can withstand six times the inner diameter of the nominal.

It is also relatively wide in the range of capillaries, and market prospects is more considerable.

Capillary is a small-diameter pipe for steel pipes, which is officially limited by it, so it can provide guarantees for various precision equipment pipeline protection, and choose the right material is very critical, and it will eventually lead the advantage that the advantages will be better, these They are worthy of us to pay more attention, need to make choices according to actual needs, this is worth more attention. In summary, choose a more high quality stainless steel capillary while identifying a more suitable specification, and the quality assurance that can be obtained will be better. Choose a better product, and more appropriate in specifications, then provide line protection for precision instruments or automated meters, so it is still a wide range of use.

After the capillary is treated, if the surface nickel element is destroyed, the corrosion resistance is definitely a bit, but it can't be said to be completely non-rust, so the capillary should not use it to expose outdoors. If the capillary is used in the room, it is not only beautiful, but for the indoor environment, rust rust is sufficient, but if you put it outdoors, pay attention to maintenance. Regularly erase the stainless steel tube, pay attention to protect the surface of the stainless steel pipe to be destroyed.

Never wipe the stainless steel pipe with corrosive cleaning liquid, it is usually scrubbed with water. This can better protect the surface of the stainless steel pipe. With the continuous improvement and improvement of production technology, new production equipment is constantly updating and improving, capillary is corrosion-resistant, and zero destruction, will become a reality!

Capillary is divided into soft styles, middle hard hustle, etc. Effective control to improve the quality of control, the hardness index and actual state of the pipe material, and is divided into bright annealing during annealing, and Ya-light annealing, gas protection light brightening furnace: There are two parts, light backing stove The furnace body is decomposed into a set device.

Light retreat stove furnace body: The main structure is arranged by a circular cross-sectional hover, and the capillary is arranged with both sides and bottom portions, and the ammonia decomposition gas is used as a protective gas and circulating cooling gas. The addition of the gas on the decrease of the gas, the actuation of the actuation is to achieve the purpose, the structure is compact, the operation is safe, the control is reliable and the maintenance is convenient, the furnace temperature is uniform (temperature can reach 1150 ° C), the source loss is low, can make full use of protective gas The cooling rate is fast, ensuring that the redepodant precipitation of chromium carbide is prevented, which allows all carbicide to completely solid dissolve into the austenitic substrate, and the hard-state and gold phase tissue of the original cold rolled tube is changed, which is truly solid solution treatment purpose.

The thin tube is a steel pipe having an outer diameter of 1 mm or more, and the stainless steel capillary is made of a plurality of ingots or solid tube billets, and then prepared by hot rolling, cold rolling or cooling. The capillaries or long or short, short, short words can be welded, and if you want to remove the extra part, it is cut off, which is the length of its length suitable for the construction capillary.

Methods of capillary cutting methods have many kinds.

(1) Use a sawing machine. The sawing machine is characterized by welding and welding in the construction. The disadvantage is that the efficiency is too low, that is, too slow.

(2) Use artificial gas cutting. Features fast, high efficiency, disadvantage is that the surface of the sproker presents a sawtooth shape, hinders and construction.

(3) Use the pipeline self-tuning automatic cutting machine. It is characterized by low cost of using a pipeline self-purification. The slider is smooth, and the steel pipe of the capillary and the cutting of the sawing machine are not too large after using the pipe self-rotating automatic cutting machine.

(1) What is the metal?

(2) Welding materials should be consistent with the base material or higher than the master material

(3) Master the appropriate welding temperature

(4) When the capillary welding, some need to flux

Non-ferrous metal capillary welding: copper, stainless steel, nickel-based alloy such alloy capillary can be welded with high-tech Weldo 88c welding wire and 88C-F flux when welding, so you don't have to find solder for each metal. Because the melting point of aluminum is very low, the soldering heating tool uses the third generation of WE53 liquefied gas, with low temperature aluminum welding Silk Ondocunding Q303 wire, only at low temperature temperature, can be safe Welding is good.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...