What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...The copper alloy refers to an alloy composed of one or several other elements that is added to the matrix of pure copper. The classification of the copper alloy is still very well understood. There are many colors of the copper alloy, different copper alloy types have different colors, the copper alloy has a color, yellow, cyan, etc.

There are a lot of methods for copper alloy classification, and there are many types of different points.

1. Brass: The alloy based on copper and zinc is also subdivided into simple brass and complex brass, complex brass, and the third set of metaded is nickel brass, silicon brass, etc.

2. bronze: refers to copper-based alloys other than copper nickel and copper zinc alloy, the main varieties are fine bronze, aluminum bronze, special bronze (also known as high copper alloy);

3. white copper: linen the copper nickel alloy;

4. Pure copper: means pure copper, the main varieties have oxygen-free copper, copper, phosphorus deoxia, silver copper.

1. Non-alloy copper: non-alloy copper includes high purity copper, tough copper, deoxic copper, oxygenless copper, etc.

2. Other copper alloys belong to alloy copper. my country and Russia divide alloy copper into brass, bronze and white copper, then divided into small alloys in large class.

1. Conductive conductivity copper alloy: mainly non-combined copper and micro-gold copper.

2. copper alloy with structure: almost all copper alloys.

3. corrosion-resistant copper alloy: mainly tin brass, aluminum brass, all kinds of non-white copper, aluminum bronze, titanium bronze, etc.

4. wear-resistant copper alloy: mainly include lead, tin, aluminum, manganese, etc., is complex brass, aluminum bronze, etc.

5. easy to cut copper alloy: copper-lead, copper-, copper-antimony and other alloys.

6. elastic copper alloy: mainly there are antimony bronze, aluminum bronze, beryllium bronze, titanium bronze, etc.

7. Damping copper alloy: high manganese copper alloy, etc.

8. art copper alloy: pure copper, simple single copper, tin bronze, aluminum bronze, white copper, etc.

1. Cast copper alloy: cast, and can also be used in deformation processing.

2. Deformed copper alloy: Deformed copper alloys can be used for casting.

3. Cast copper alloy and deformed copper alloy can be subdivided into cast copper, brass, bronze and white copper.

As a kind of processing, the copper alloy has many kinds. Let's take a copy of the copper alloy processing: divided into eight kinds of varieties such as plate, strip, foil, arrangement, pipe, bar, wire and profile (commonly known as eight categories).

In general, when the thickness of the strip is less than 0.1 mm (my country's customs is called less than 0.15 mm foil), the division of the bar and wire is less than 5 mm in diameter in addition to the straight strip and the reel. The reel shape is called a wire, and the line is referred to as a small bar.

1. Copper alloy sheet with foil: copper alloy sheet belt foil product products according to the dimensions and fine public as a plate, strip, strip and foil.

(1) Copper alloy sheet

The final rolling state of the copper alloy sheet with foil products is divided into hot rolled sheets and cold rolled sheets.

The common dimension range of hot rolled sheets is: 4 to 150 mm (thickness) × 200 ~ 3000mm (width) × 500 ~ 6000mm length.

The common dimensions of the cold rolled sheet are: 0.2 to 12 mm (thickness) × 100 ~ 3000mm (thickness) × 500 ~ 6000mm (length).

The status of the sheet product includes hot rolled state (R), soft state (M), half hard state (Y2), hard state (Y), special hard state (T) and heat treatment state (CS).

(2) Copper alloy strip

The strip size ranges from 0.05 to 3 mm (thickness) to 10 to 1000 mm (width), and it is contained. Soft-state (M), half hard (Y2), hard (Y), and hardness (T).

(3) Copper alloy strips (also known as copper belts)

The thickness of the strip is between the sheet and the strip, the size range is generally: 0.2 to 10 mm (thickness) × 50 to 100 mm (width) × 1500 to 2000 mm (length). Commonly used strips products include pure copper strips, brass strips, bronze strips, etc.

(4) Copper alloy foil: domestic copper processing foil refers to plates and strips of thickness at 0.05 mm or less, and has a plate and strip with a thickness of 0.1m or less. It is a rolled copper foil (translucent copper foil). Electrolytic copper foil is not included.

Commonly used foil products include pure copper foil, brass foil, bronze foil, white copper foil.

The foil size range is: 0.05 ~ 0.1mm (thickness) × 40 ~ 600mm (width), the volume is supplied, and the length should not be less than 5000mm, and its state is softer (M) and hard state (Y). Copper alloy foil products are highly hard, pure copper products with no greater than 0.02 mm, are generally hard-state.

2. Copper alloy tube rod wire: The copper alloy tube rod wire is finely divided into pipe, bar and wire according to the product shape.

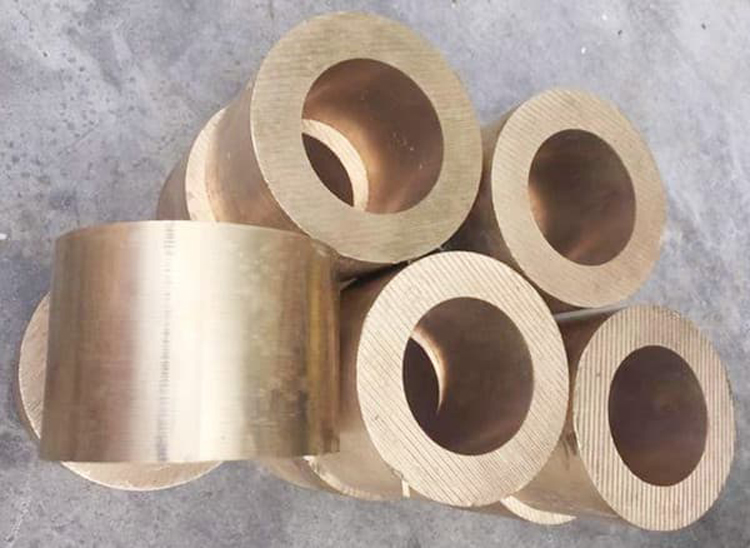

(1) Copper alloy tube: tube is divided into circular, trapezoidal, triangle, rectangular tube and square tube, its size range: 0.5 ~ 360mm (outer diameter) × 0.1 ~ 50mm (wall thickness), straight or roll The state of the goods, the product is divided into state (R), soft state (M), light soft (M2), hard (Y), semi-hard state (Y2), 1/3 hard (Y3) product.

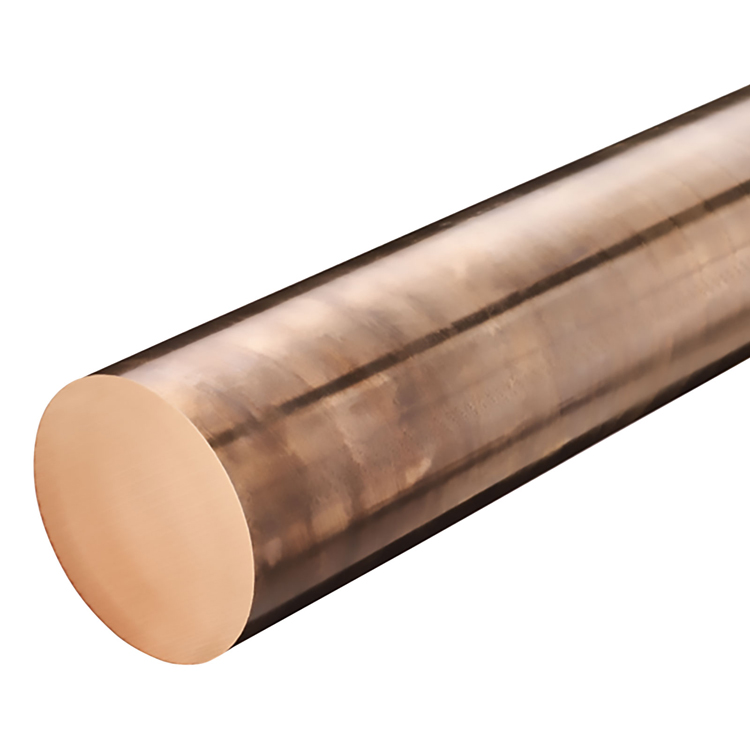

(2) Copper alloy bar: copper alloy rod, copper alloy round rod, copper alloy hexagon stick, copper alloy square stick, copper alloy rectangular rod, copper alloy guide, its size range of 3 ~ 120mm (diameter) × 500 ~ 5000 (length), straight line supply, product status is divided into state (R), soft state (M), forged state (M2), hard (Y), half hard state (Y2), soft Time-acting (TF00), hard time-acting (TF04) product.

(3) Copper alloy disc: The copper disc strip refers to the billet of the production wire, also known as the copper rod. The split beam and black rods are spurred, and the black rod is hot rolled on a boat-shaped ingot, and the surface oxidation is severe, and it has been basically eliminated. The diameter of the strip is between 6 to 20 mm, produced by a continuous casting or superior (or horizontal).

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...