What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

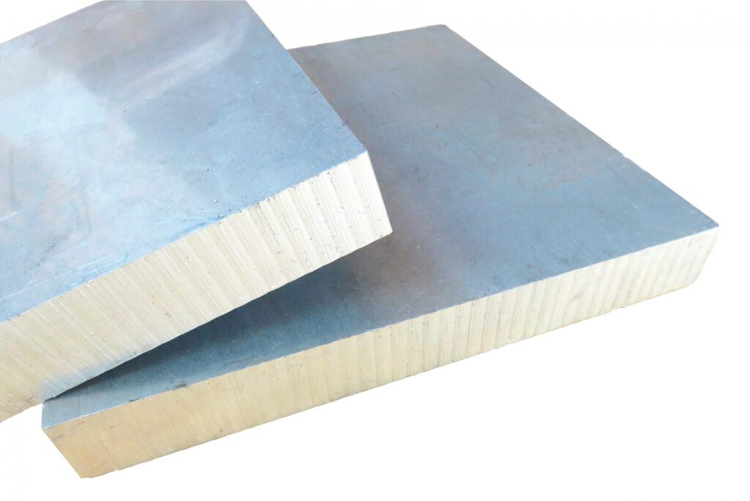

What is the difference between 201 st...Aluminum alloys can be divided into two categories: cast aluminum alloys and deformed aluminum alloys according to their composition and process properties. Deformed aluminum alloys are divided into four categories: anti-rust aluminum, duralumin, super hard aluminum and forged aluminum according to their performance and process performance.

The main alloying elements in rust-proof aluminum are manganese and magnesium, which belong to Al-Mn and Al-Mg alloys. This kind of aluminum alloy belongs to the aluminum alloy that cannot be strengthened by aging. After forging and annealing, it is a single-phase solid solution, so it has high corrosion resistance and good plasticity. Manganese in aluminum can lift the strength of aluminum alloy through solid solution strengthening, but its main function is to improve the corrosion resistance of aluminum alloy. Manganese alloys have good corrosion resistance. Magnesium has less damage to the corrosion resistance of aluminum alloys, and has better solid solution strengthening effect.

Anti-rust aluminum has a strong ability to withstand pressure processing, and can be processed by cold pressure processing to produce processing strengthening. It also has good weldability and poor machinability (because it is too soft). Anti-rust aluminum is used to make parts that are corrosion-resistant and less stressed, such as oil pipes, fuel tanks, rivets, etc.

Duralumin is basically an AU-Cu-Mg alloy, which also contains a small amount of manganese and copper and magnesium. In addition to solid solution strengthening, it also forms strengthening phases such as CuA12 (theta phase) and Al2CuMg (S phase). The addition of manganese is mainly to improve the corrosion resistance of the alloy, and also has a certain solid solution strengthening effect, but the precipitation tendency of manganese is small, so it does not participate in the aging process. All kinds of duralumin can be age-strengthened; the higher the content of copper and magnesium in the alloy, the more significant the effect of age-strengthening, the higher the strength, but the lower the plasticity and corrosion resistance. According to the alloying degree, mechanical properties and process properties of the alloy, duralumin can be divided into spliced duralumin (2A01, 2A10), medium-strength duralumin (2Al1), free-strength duralumin (2A12, 2A06) and heat-resistant duralumin (2A02) )Wait.

Duralumin is the most widely used type of deformed aluminum alloy in the aviation industry at present. It has strong aging hardening ability, and its strength can reach up to 500MPa after heat treatment. It is used to make various load-bearing components in aircraft.

The corrosion resistance of duralumin is poor, especially in seawater. This is because it contains high steel, and the electrode potential of copper-containing solid solutions and compounds is farther from the grain boundary, which is easy to cause intergranular corrosion.

Super hard aluminum is mainly based on Al-Cu-Mg-Zn system, such as 7A04. In addition to the θ phase and the S phase, the aging strengthening phase includes MgZn2 (η phase) and Al2Mg3Zn3, (T phase) with a strong strengthening effect. Room temperature strength after quenching and aging treatment.

It can exceed 600MPa, which is a deformed aluminum alloy with the highest strength. The disadvantage of this alloy is poor fatigue resistance, sensitivity to stress concentration, obvious stress corrosion tendency, and lower heat resistance than duralumin.

Wrought aluminum belongs to Al-Mg-Si-Cu and Al-Cu-Mg-Ni-Fe alloys. Although there are many types of alloying elements in this type of aluminum alloy, the content of each element is small, so it has good thermoplasticity and is suitable for making various forgings for aviation, especially large forgings with complex shapes. The addition of copper, magnesium, silicon and other elements can form Mg2Si, Al2CuMg, CuAl2 and other compounds in the alloy. When iron and nickel are added, the service temperature of the alloy can be increased, so it is called heat-resistant forged aluminum alloy. Commonly used forging aluminum alloys are 6A02, 2A50, 2B50 and 2A14. Its supply state is generally quenching and artificial aging.

For aluminum alloys that need to work at the separation temperature, a small amount of transition group elements such as manganese, chromium, germanium, and titanium are usually added. The dissolution of these elements into the matrix can strongly increase the recrystallization temperature. When the dispersed second phase is precipitated, it can effectively to prevent the recrystallization process and grain growth. The recrystallization temperature is also an index reflecting heat resistance.

Excessive content of alloying elements in the deformed aluminum alloy will cause a serious decline in the plasticity and corrosion resistance of the alloy process, and even make the pressure processing of the alloy difficult. Therefore, w(Cu) in the deformed aluminum alloy generally does not exceed 5%, w(Mg) does not exceed 2.5%-5%, w(Zn) is 3%-8%, and w(Si) is generally 0.5%- 1.2%. Elements such as iron and silicon are harmful impurities in deformed aluminum alloys.

Most wrought aluminum alloys have good forgeability and can be used to produce forgings of various shapes and types. Aluminum alloy satin parts can be produced by various existing forging methods, including free forging, die forging, forging, roll forging, rolling, spinning, ring rolling and extrusion. The flow stress of aluminum alloys varies significantly with composition, with the highest value of the flow stress in each alloy being approximately twice the lowest value (i.e., the required forging load differs by approximately twice); some low-strength aluminum or aluminum alloys, such as 1100 (equivalent to industrial pure aluminum 1200) and 6A02, its flow stress is lower than that of carbon steel. And high-strength aluminum alloys, especially Al-Zn alloys, such as 7075 (LC4), 7049 (LC6), etc., their flow stress is significantly higher than that of carbon steel. Some other aluminum alloys, such as 2219 (LY16), have flow stress very similar to carbon steel. As a class of alloys, aluminum alloys can generally be considered more difficult to forge than carbon steel and many alloy steels, but compared with nickel or cobalt-based alloys and titanium alloys, aluminum alloys are significantly easier to forge, especially when isothermal die forging is used. in the case of technology.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...