What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...With the development of building doors and windows, curtain walls, building decorations, and car and boat decoration industries, the processing of professional aluminum profiles has gradually developed into an independent processing intermediate category. According to the characteristics of aluminum materials and processing processes, this processing generally has the ability to milling, drilling, and attack wire. However, the functions of milling plane/curved surface, holes, pores, etc. are rarely used in aluminum profile processing. Due to the uniqueness of the processing object, the intermediate aluminum profile processing is very different from the middle processing in terms of structural layout, technical parameters, and CNC system design:

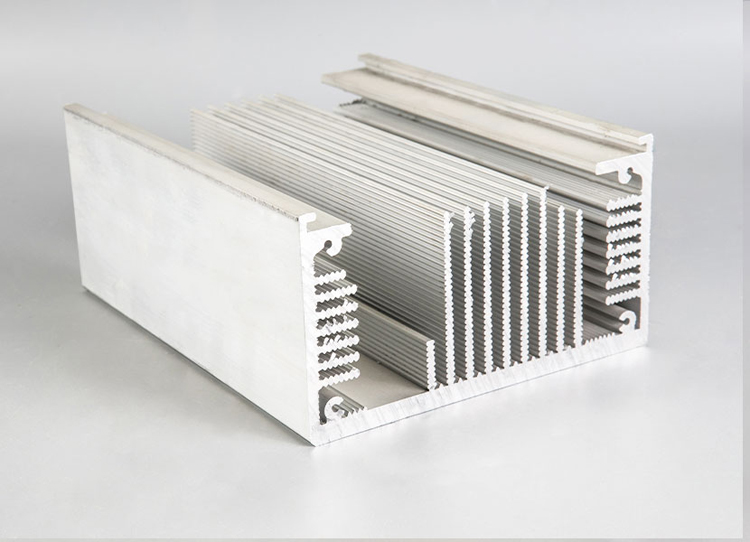

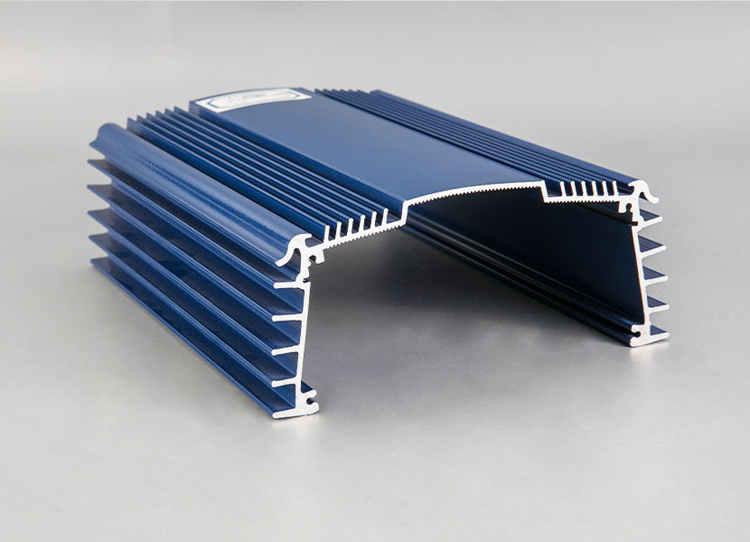

(1) Professional aluminum profile processing intermediate characteristics, long vertical itinerary. In order to adapt to the characteristics of the slender parts of aluminum profiles, most of the workbenches in the middle of the aluminum profile processing are narrow and long. The workbench is equipped with pneumatic fixture and positioning board to facilitate the positioning of the workpiece.

(2) The spindle speed. Due to the fast speed, the integrated permanent magnet synchronous electrical spindle with functions such as clamping, air cleaning, and circulating water cooling is generally used. After the surface of the industrial aluminum profile is oxidized, the appearance is very beautiful and resistant. Once you apply oil, it is easy to clean. When assembling products, different specifications are adopted according to different loads, and the supporting aluminum profile accessories are used. No welding is required, more environmentally friendly. And light weight, easy to carry and move when installing and disassembling.

Industrial aluminum profile is alloy material with aluminum as its main ingredient. Perm the aluminum rods into aluminum at different sections. However, the mechanical properties and applications of industrial aluminum profiles are also different.

In the customization of industrial aluminum profiles, distortions and deformation often occur. In fact, this is mainly due to the uneven metal flow during the manufacturing process, and there are many reasons for uneven metal flow.

How do you know the material of aluminum alloy industry aluminum profiles?Many friends want to use aluminum -type materials for the first time, but they cannot distinguish materials because everyone does not know what the brand standards of their industry application materials are? In order to let you know how to choose aluminum materials used in your own industry, the following is a simple material difference.

Aluminum profiles are made of aluminum alloy, forming a hardness aluminum stick, and then squeezing. For example, 6005, 6060, 6061, 6063, 6082 and other 6 series of aluminum profiles are widely used in the industrial field. Equipment, workshop workbench, industrial steps, robotic fences, truss robotics, machine cover, ceiling, etc.

Another type of hardness, 2 series 2024, 2A7003 series 7003 materials, 7005 materials, 7075 materials, etc., also known as aviation aluminum profiles, for high intensity such as aviation and ships. Due to hardness, the product design structure is relatively simple, and the complex cavity cannot meet the squeezing conditions.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...