What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

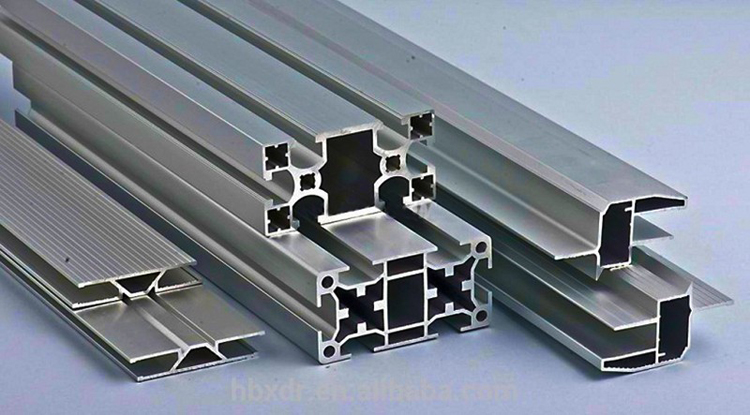

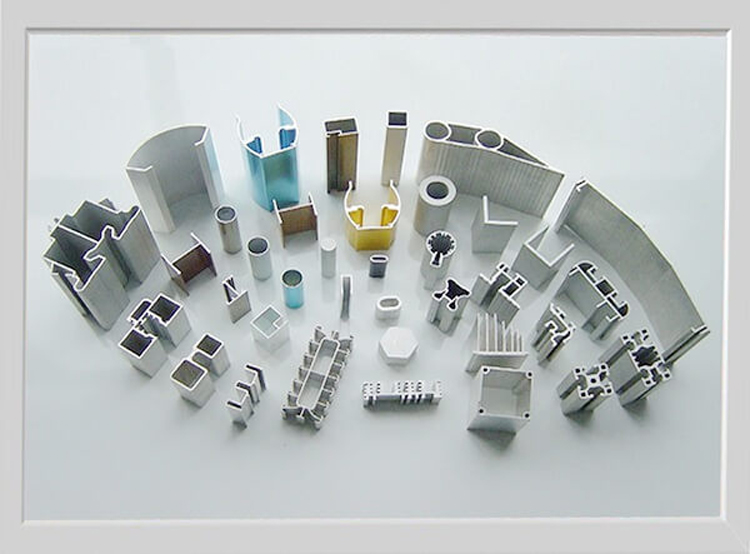

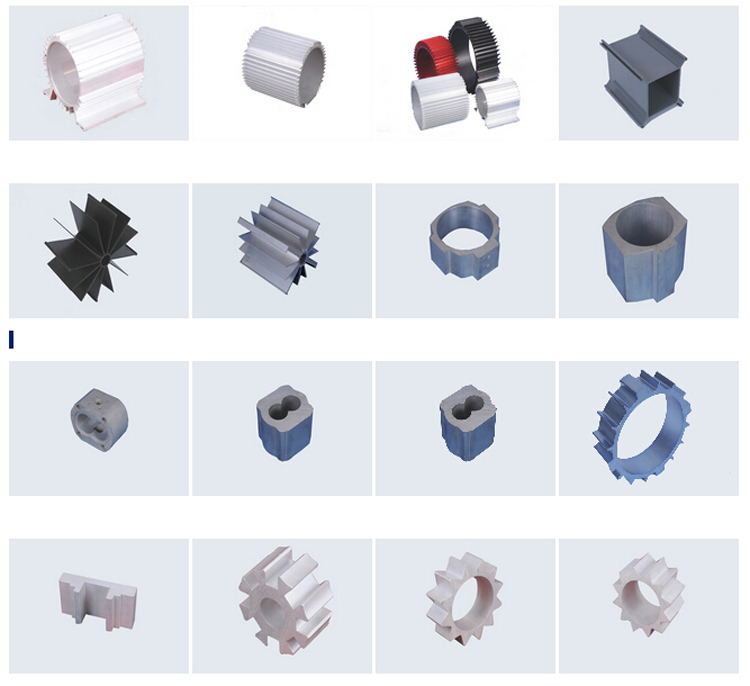

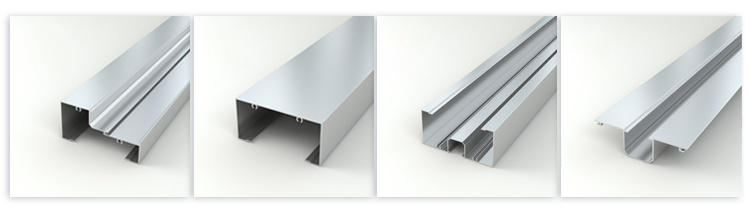

What is the difference between 201 st...Industrial aluminum profile is one of the commonly used building materials.Aluminum profiles are products manufactured from aluminum and other alloying elements. Aluminum extrusions are usually aluminum rods with different cross-sectional shapes and appearances obtained by hot-melting, extruding, and then undergoing various surface treatments. The main metal element is aluminum, and some alloying elements are added to improve the performance of aluminum.

At present, industrial aluminum profiles are a relatively common material in the production and life of modern society. Compared with traditional materials such as iron and stainless steel, the use of high-strength industrial aluminum profiles has the following advantages:

1)Industrial aluminum profiles only need to be designed, cut, drilled and assembled; while traditional mechanical manufacturing materials usually go through complex processes such as design, cutting, drilling, welding, sandblasting, surface treatment, and painting.

2)There is no thermal welding in the whole production process of the industrial aluminum profile generator, so the parts are easy to disassemble, and all materials and accessories can be recycled and reused; while traditional machinery manufacturing materials are due to cutting deformation and high cost Dismantling costs, etc. and you rarely reuse.

3)Due to the simple production process of industrial aluminum profiles, a lot of labor costs can be saved; especially when rework is due to production errors, it saves several times the man-hour than using traditional machinery.

4)Industrial aluminum profiles have not undergone thermal welding during the production process, and the material is not deformed, so the assembly accuracy is high; while the traditional mechanical manufacturing materials using thermal welding cannot be deformed, thus affecting the final assembly accuracy.

5)The aluminum profiles of the assembly line have many varieties, complete specifications, suitable prices, and a wide range of applications; light unit weight, good mechanical properties, high connection strength, and large bearing capacity.

6)The size is standardized, the tolerance is strict, the appearance is generous, the finish is good, and the corrosion resistance is used.

7)The equipment made of industrial aluminum profiles has a more modern appearance, and its unique anodized coating is more firm and stable than the existing various coating methods.

With it, the operators in the factory can be faster, as well as convenient, simple and thus more efficient. The application of industrial aluminum profiles can be assembled in various shapes.

1)Aluminum profiles for aerospace: making aircraft skins, fuselage frames, beams, rotors, propellers, mailboxes, siding and landing gear struts, as well as rocket forging rings, spacecraft siding, etc.

2)Aluminum materials for transportation: It can provide all kinds of aluminum alloy materials for automobiles, large-scale porous profiles for subways and light rails to fill the domestic gap, and meet the requirements of localization of subways for the manufacture of automobiles, subway vehicles, railway passenger cars, and high-speed passenger cars. The car body structure, doors and windows and shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and marine materials.

3)Aluminum material for packaging: All-aluminum pop-top can material is a sign to measure the level of aluminum processing in a country. Widely used in beverages, food, cosmetics, pharmaceuticals, cigarettes, industrial products and other packaging.

4)Aluminum type for printing: The printing industry bid farewell to "lead and fire" and entered the era of "light and electricity". Aluminum for printing is mainly used to make PS plates. Aluminum-based PS plates are a new type of material in the printing industry, which are used for automatic plate making and printing. The aluminum-based PS plate provides a strong support for this change in printing.

5)Aluminum for electronic appliances: mainly used in various busbars, wires, conductors, electrical components, refrigerators, cables and other fields. Aluminum foil for air conditioner has excellent deep drawing performance, high strength and good extensibility, reaching the level of similar imported products; high-performance electrolytic capacitor foil fills the domestic gap. Specifications: round bar, square bar, representative uses include aerospace fixtures, electrical fixtures, and communications.

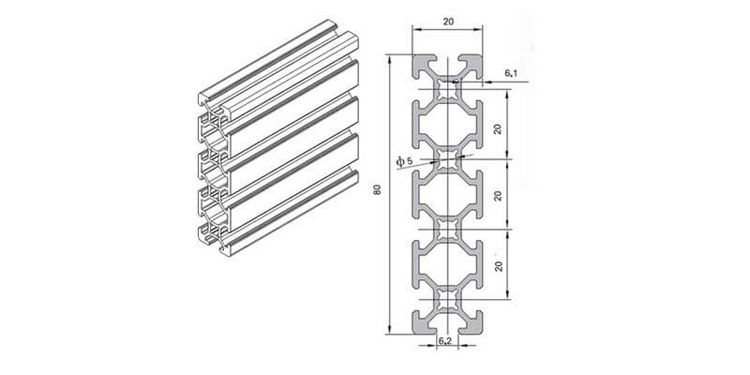

1)There are various specifications and sizes, and the size of the long side and the short side is a multiple. For example, our common 4040, 4080, 40120, and 4040 are square, with four sides of 40mm, and 4080 is the long side of 80mm. The short side is 40mm, and the long side is twice as long as the short side. Of course, there are also special ones, such as 4060, the long side is 1.5 times the short side.

2)There are only two notch widths, 8mm and 10mm. Although there are hundreds of thousands of specifications for industrial aluminum profiles, their notch basically has only these two sizes, which are very small. For example, the 2020 notch is 6mm, so is to use conventional accessories.

3)There are two kinds of national standard and European standard. The difference between the European standard aluminum profile and the national standard aluminum profile is also in the notch.

The connectors used in the national standard and the European standard are also different. The European standard has more specifications than the national standard. There are also some customized non-standard industrial aluminum profiles, which can be used for both European standard connectors and national standard connectors.

4)The wall thickness of industrial aluminum profiles will not be too thin. Unlike architectural aluminum profiles, some industrial aluminum profiles only play a decorative role. The wall thickness will be very thin. Industrial aluminum profiles generally play a supporting role. A certain load-bearing capacity, so the wall thickness cannot be too thin.

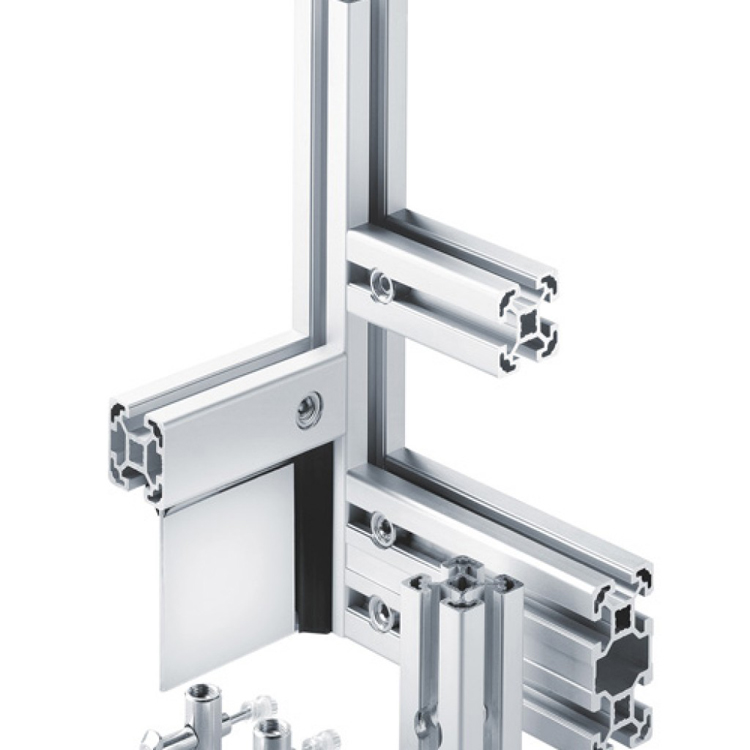

Corner fittings are often used in the use of industrial aluminum profiles, and are generally used for vertical or cross-connection of industrial aluminum profiles. There are mainly three types of corner fittings, strong corner fittings and steering angle. Angle pieces are often used to strengthen the supporting force of the connected points of industrial aluminum profiles, and can also be used as a way of connecting profiles that need to be moved; strong corner pieces are often used for the support and fixation of strong or vibrated profiles and profile points; steering corner pieces Profile connection for crossing.

Common corner pieces are: steering corner pieces, right-angle brackets, right-angle pieces, strong right-angle brackets, 45-degree brackets, 135-degree angle brackets, 9090 strong angle brackets…

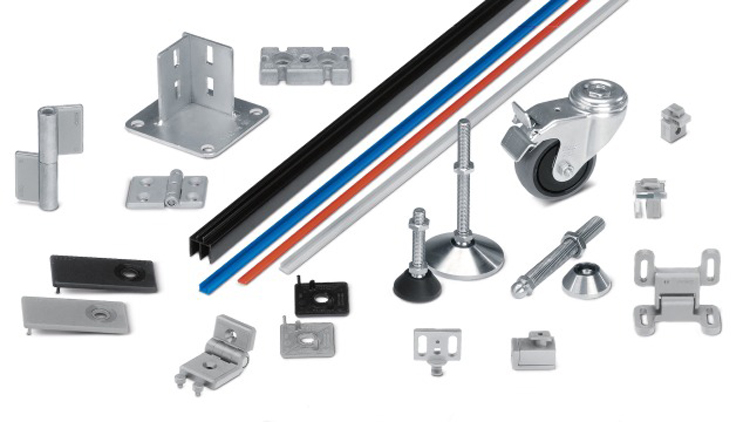

The end face connecting plate is mainly used for connecting rectangular and large-sized hollow square profiles with hoof corners and casters. When using the spacer connection block, insert the end of the connection block directly into the groove of the profile, and fix it tightly on the profile after rotating 90%, and then install various panels such as plexiglass on the connection block, and then lock it with bolts. Tight, easy to install and easy to disassemble.

Common special connectors for profiles include: special corner slot connectors, bevel connectors, three-dimensional corner connectors, anchor connecting pins, corner slot connectors, living hinges, elastic fasteners, groove connectors, connecting plates, built-in connections pieces and so on...

The industrial aluminum profile frame generally adopts the internal link method, using special semi-circle head bolts or special bolts. Before installation, it is necessary to tap threads and process installation holes at the profile connection.

Common bolts and nuts include: special cylinder head bolts, special semicircle head bolts, flat machine bolts, slider nuts, flange nuts, square nuts, elastic nuts, shrapnel nuts, t-bolts, t-nuts, etc...

The table page is used for the active connection between profiles and profiles or profiles and plates. The end face cover is installed on the end face of the profile, which is both beautiful and safe. The movable hook can be inserted into the groove of the profile to slide back and forth, and hook various tools, wires and other objects. The flat seal groove can cover the groove on the surface of the profile, play a decorative role, and also keep the surface of the profile clean. After the U-shaped groove strip is put into the groove of the profile, the plexiglass and other plates can be inserted to play the functions of buffering, protection and sealing. The handle is mounted on the profile for easy opening and carrying. The lifting eye is installed on the end face of the profile for lifting.

Common aluminum profile assembly decorative parts include: flat seal grooves, metal/nylon hinges, spacer connection blocks, nylon/metal movable hooks, stainless steel door suctions, handles, grooves, moldings, etc.

The hoof horn is a general accessory for various industrial aluminum profile frames and equipment. It has the functions of support and shock resistance, and its screw can be used to adjust the height. Precise casters with quiet, dust-proof and stacking brakes can be installed on the frames of machines and carts made of aluminum profiles.

Common styles are: screw type casters, flat type casters, compound casters, Foma casters, joint feet, square feet, foot corner pieces, etc...

The elastic fastener has the function of anti-loosening and anti-vibration. When the two sections of profiles are connected at right angles, insert the elastic fastener into the groove of the industrial aluminum alloy profile, and then connect the two sections of profiles with special bolts. The car joints of the profiles should be pre-drilled and Tapping thread, this connection method is firm and firm, which can effectively prevent the connection from loosening.

Common styles include: elastic fasteners for industrial aluminum profiles, living hinges for industrial aluminum profiles, etc...

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...