What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...The top five elements of the largest content in the crust are oxygen, silicon, aluminum, iron, calcium. Aluminum is a large amount of elements existing only in oxygen and silicon, and is a metal element in the crustal content.As the largest colored metal in global production, aluminum is widely used in construction, packaging, transportation, electricity, aerospace and other fields, is an indispensable basic raw material for national economic construction, strategic emerging industries and national defense technology industries.

Aluminum is a metal having 13 excellent properties.

Can withstand -200 ℃ low temperature. It is a low temperature resistant material.Contrary to steel, which loses strength at low temperatures, aluminum increases in strength at low temperatures. Aluminum is used not only as a container material for LNG (-162°C), but also in cutting-edge fields such as aerospace development and bioengineering.

Aluminum is able to conduct electricity. It is a high-quality metal that can be used as an economical electrical conductor.Although the conductivity of electricity is worse than that of copper, it can pass twice the current of copper of the same weight because of its lighter specific gravity. Therefore, 99% of high-voltage transmission lines are made of aluminum. In other fields such as energy utilization and electronics, the demand for aluminum is gradually expanding.

Because aluminum can reflect light and heat. Therefore, it can also be used for the production of space suits.High-purity aluminum can fully reflect infrared and ultraviolet, radio and radar electromagnetic waves. Utilizing this characteristic, it can be used in reflectors for heating equipment, lighting fixtures, and space suits.

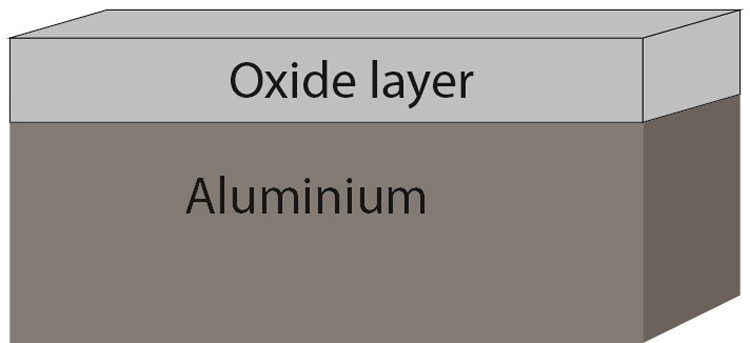

Naturally prevents rust and corrosion. Excellent corrosion resistance.Aluminum can naturally form an oxide film in the air, this film can prevent corrosion, so it will not rust like iron. Aluminum's excellent corrosion resistance makes it shine in the fields of construction, automotive, marine and marine development.

The specific gravity of aluminum is 2.71. About one-third of iron (7.87) and copper (8.93).Taking advantage of its lightweight characteristics, it can not only improve the fuel consumption rate and performance of transportation fields such as automobiles, railway vehicles, aircraft and ships, but also realize high performance of products in various fields such as civil engineering/construction and mobile home appliances.

Aluminum is not toxic. It is a harmless and odorless sanitary material.Because aluminum is different from heavy metals, it will not harm human health and will not pollute the soil, so it is widely used in the packaging of food and medical supplies, beverage cans, medical machines and household appliances.

Aluminium can be melted at low temperatures and can produce castings of complex shapes.Because aluminum has a lower melting point than iron and copper and is easy to cast, thin and complex shaped castings can be easily produced. It is widely used in various fields such as piston and wheel manufacturing, automotive parts, industrial machinery parts, and camera bodies.

Aluminum is not only lightweight but also strong. If processed, the firmness will be greatly improved.Adding other metals to pure aluminum to make alloys, or through processing such as rolling and heat treatment, can improve the strength of aluminum materials. Aluminum has attracted great attention as a material that can be used in aircraft and large-scale devices.

Easy to recycle. Shine bright in the field of global environmental protection.Compared with other metals, aluminum can be easily recycled, and the quality of the recycled product is the same as the new one, without any change. It can contribute to energy saving and resource saving, and is an extremely important metal material in the field of environmental protection.

It was beautiful. Prettier after processing.Although aluminum itself is beautiful in texture, it can be even more beautiful when it is surface treated. At the same time, it can also be colored, which is suitable for areas that pursue a sense of design, such as architectural exteriors and packaging materials.

Aluminum is a non-magnetic substance. Not magnetic.Because aluminum is not affected by magnetic fields, its application range is expanding in parabolic antennas, ship measurement equipment, electronic medical equipment, and mechatronic products.

Aluminum has excellent workability. Many different shapes can be produced.Ease of processing is a major feature of aluminum. Aluminium can be formed into a variety of processes, from thin foils like aluminium foil to extruded profiles of complex shapes. At the same time, because aluminum can be easily and precisely processed, there are many industrial fields in which aluminum is active.

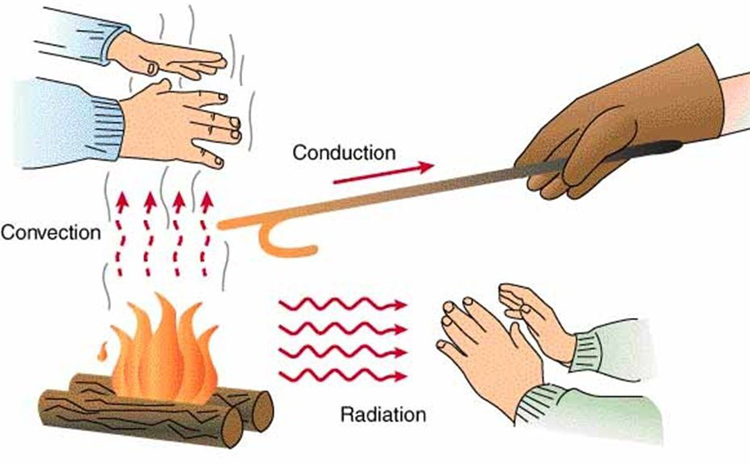

Heating and cooling are convenient. The thermal conductivity is about 3 times that of iron.Aluminum not only transfers heat, it also has the property of rapid cooling. It is widely used in daily necessities such as pots, beverage cans, coolers and heaters, various heat exchangers, and heat sinks and radiators for heat dissipation purposes.

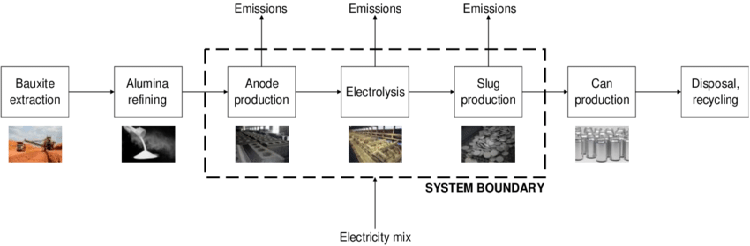

The aluminum industry chain mainly consists of four links: bauxite mining, alumina refining, primary aluminum production and aluminum processing. The first is bauxite mining, and then alumina is extracted by dissolving, filtering, acidifying and burning the bauxite, and then electrolytic aluminum is prepared by electrolytic melting. Electrolytic aluminum can be further processed into various aluminum materials, aluminum alloys and aluminum powders after being remelted and purified.

The aluminum industry chain continues to expand in the process of technological upgrading, from the initial simple casting, rolling and extrusion to the field of precision machining, and continuously expands the field of aluminum applications. Currently, it is widely used in emerging fields such as high-speed rail, urban rail, solar panels, electric vehicles, nuclear power, etc. . The highest technology aluminum deep processing is high-voltage electronic aluminum foil, brazing foil, etc. used in electronic equipment, automotive and aviation fields.

The upstream industrial chain of aluminum includes bauxite mining, alumina refining and primary aluminum production.

Global reserves of bauxite are abundant, mainly concentrated in countries close to the equator, including Australia, Guinea, Brazil, Vietnam and Jamaica, accounting for 64% of the world's total reserves. my country's reserves only account for 3% of the world's reserves, but the distribution is highly concentrated. The four provinces of Guangxi, Henan, Shanxi and Guizhou together account for more than 90%.

Alumina is an intermediate link, and its output is mainly distributed in China, Australia and Brazil. China imports a large amount of bauxite from overseas, which is finally produced into alumina, and China's alumina output accounts for about 50%, which can basically meet the needs of electrolytic aluminum. Production needs, only a small amount of imports.

The primary aluminum is processed into aluminum processed materials, which are used in various downstream industries. Aluminum processing is divided into two forms: deformation processing and casting processing:

①Deformation processing: It is divided into two methods: extrusion and calendering.Products made by extrusion process are called extruded profiles, mainly including building profiles and industrial profiles; products made by calendering process are called sheet, strip and foil materials, mainly including various aluminum sheets, strips and foils.

②Casting processing: The original aluminum is processed into various precision aluminum alloy die castings and precision sheet metal by die casting.Aluminum alloy die castings are mainly concentrated in the two major consumption areas of communication equipment structural parts and auto parts.

The downstream application fields of aluminum processing materials are very extensive, which are closely related to the industry, construction industry, and the improvement of consumption levels. From the perspective of downstream demand for aluminum processed materials, the construction sector is the largest consumer sector, followed by industrial sectors such as transportation, durable consumer goods, and power electronics.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...