What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...Incoloy is a nickel-chromium-iron alloy designed to resist oxidation and carbonization at elevated temperatures.There are many types of Incoloy alloys: common ones such as Incoloy800, Incoloy800H, Incoloy800HT, Incoloy825, Incoloy840, Incoloy901, Incoloy925, Incoloy20, Incoloy330, Incoloy 25-6Mo, etc.

Today, I will let you know about Incoloy800, Incoloy800H, and Incoloy800HT. At first glance, do you think that these three are not the same grades, but they are not. These three grades have slight differences in trace elements.

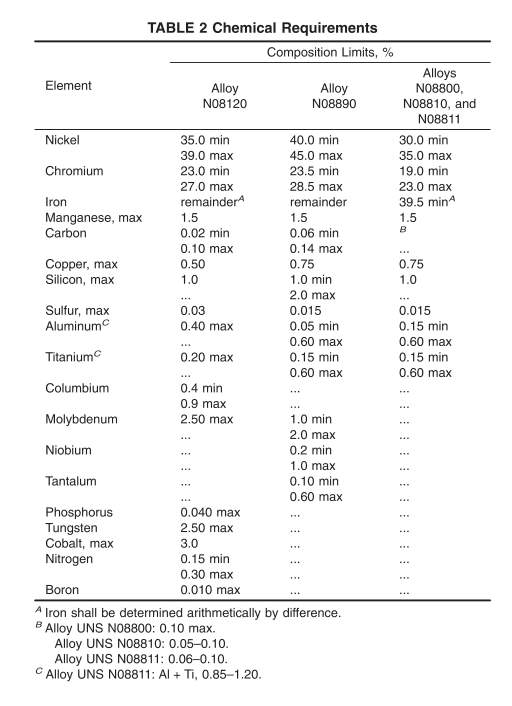

According to the chemical composition in American Standard ASTM B409, it can be seen that:

The main elements of the three grades are roughly the same, except for the difference in trace elements, in which the content of Al+Ti of 800HT is 800h higher.

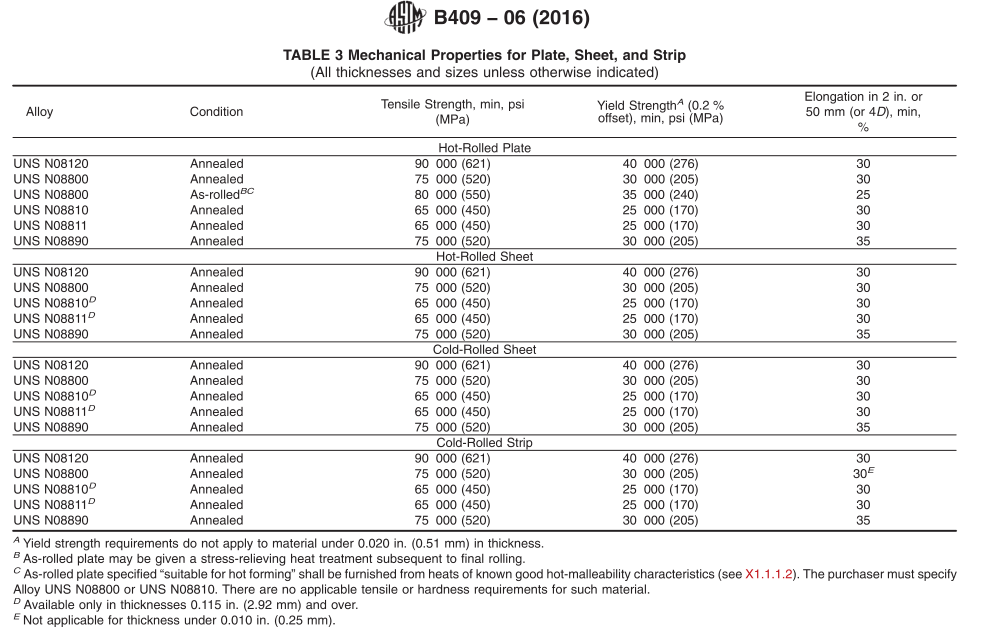

From the mechanical properties, it can be seen that the performance difference between 800H and 800HT is not very big.

(1) Excellent corrosion resistance in extremely high temperature aqueous media up to 500°C.

(2) Good resistance to stress corrosion.

(3) Good workability.

Incoloy800, Incoloy800H, and Incoloy800HT are all face-centered cubic lattice structures. Very low carbon content and increased Ti:C ratio increase structural stability and maximum resistance to sensitization and intergranular corrosion. A low-temperature annealing around 950°C ensures a fine-grained structure.

Incoloy800, Incoloy800H, Incoloy800HT can resist corrosion of many corrosive media. Its high nickel content makes it resistant to stress corrosion cracking in aqueous corrosion conditions. The high chromium content provides better resistance to pitting and crevice corrosion cracking. The alloy has good corrosion resistance to nitric acid and organic acids, but limited corrosion resistance in sulfuric acid and hydrochloric acid. Good corrosion resistance in oxidizing and non-oxidizing salts, in addition to the potential for pitting corrosion in halides. It also has good corrosion resistance in water, steam and mixtures of steam, air and carbon dioxide.

Incoloy800, Incoloy800H, Incoloy800HT application range:

(1) Nitric acid condenser——nitric acid corrosion resistance.

(2) Steam heating tube—— good mechanical properties.

(3) Heating element tube —— good mechanical properties.

For applications up to 500°C, the alloy is supplied in the annealed condition.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...