What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...

Mirror aluminum plate refers to aluminum plates that make the surface of the board showing mirror effect by rolling and polishing. Generally, mirror aluminum plates abroad use rolling methods to create rolling and plate.

The mirror aluminum plate belongs to high -end aluminum. The key aluminum alloy material models are 1050 aluminum plate, 1060 aluminum plate, 3003 aluminum plate, and its 1100 aluminum plate. According to the required production, processing and manufacturing mirror aluminum, the main use of the mirror aluminum is different, and the actual application of aluminum alloy model models is also different.The main feature is:

1) The surface layer is smooth, easy to remove

The surface of the mirror aluminum plate is smooth. Even if there is dust, just use a towel to carry out a simple removal to achieve the ideal effect of ideals. Most of the color tones are silver, which can highlight the characteristics of neat, clean and tidy.

2) Beautiful luster, enhancement of beauty and generosity

The mirror aluminum plate has a variety of tones, and the lighting effect is very good, and it has a strong reflection surface working ability. It is often used in building decorative materials and car beauty decoration to highlight the design and its overall structure, enhance the beauty and generosity, and be a true self.

3) Light materials, green environmental protection

The materials are light and reduced a lot of energy consumption. For example, Moriyu is a large number of mirror aluminum plates, which not only looks good, but also not easy to oxidize the air, and the period of use is longer.

First of all, the mirror aluminum plate must be stored in the room. In other words, the mirror aluminum plate cannot be stored outdoors to prevent precipitation and water mist. If the mirror aluminum sheet may be oxidized quickly after the rain is poured, the surface layer is long and foggy, and the actual effect of returning light is not available. Secondly, it is stored in a dry natural environment. Although it is said that the indoor air cannot drizzle precipitation, but if the water in the air is very large, then the mirror aluminum plate will still be oxidized and fade, so it is also important to store and release under the natural environment. If there is a standard, use a wet drying equipment. If there is no standard, it will use a natural ventilation and dryness method. Use a centrifugal fan to compare the mirror aluminum plate or alloy aluminum plate.

The application of aluminum plates is widely used. It is widely used in lighting lamp reflective board and lamp decoration, solar heat collecting reflective materials, interior building decoration, exterior wall decoration, household appliance panel, electronic product shell, furniture kitchen, car interior and exterior decoration, sign, logo, luggage, jewelry boxes, jewelry boxes Fields.

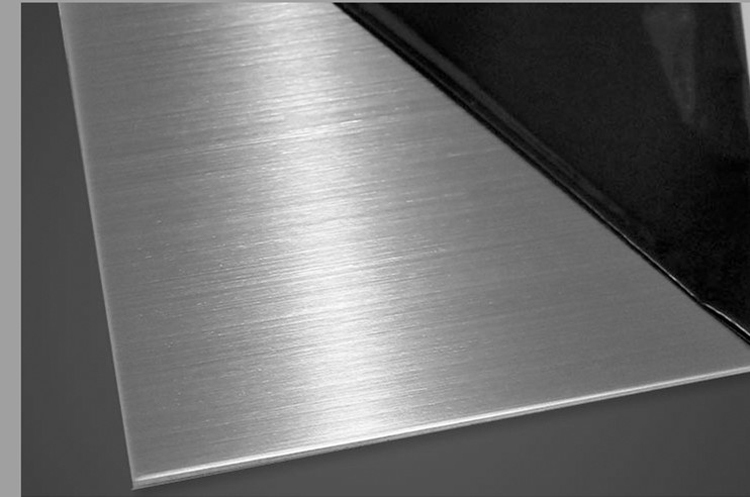

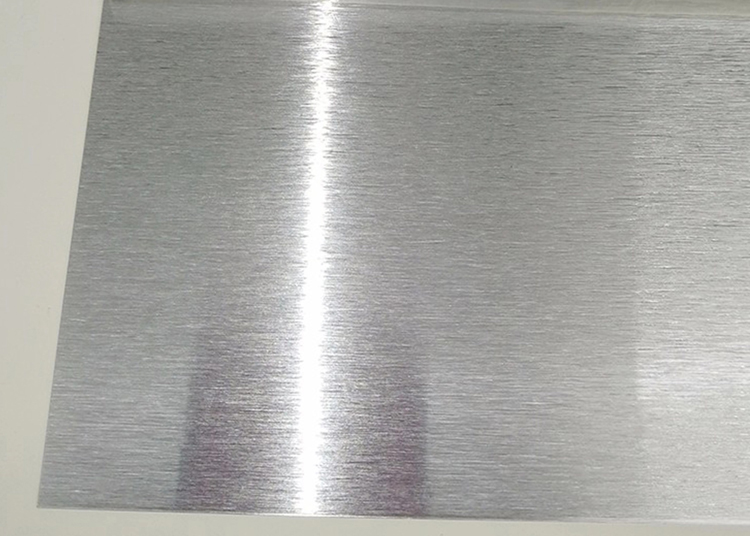

The brushed aluminum plate is a manufacturing process that repeatedly uses sandpaper to scrape the lines of the aluminum plate. Its process process is mainly divided into three parts: dehydrated, sand mill, and water washing. In the process of drawing the aluminum plate, the special cortex technology after the anode treatment can generate a cortex layer containing the metal component on the surface of the aluminum plate, which clearly shows each fine silk marks, so that the metal matte appears in the metal matte. Silk. More and more metal shells of aluminum plate products use metal brushes to play a beautiful and anti -erosion effect. Make products with both fashion and technology elements. This is also one of the reasons why this process is very popular.

1) The brushed aluminum plate is fashionable, has a soft metal texture, is rich in color, and can be customized.

2) The corrosion resistance of the brushed aluminum plate is 3 times, anti-static, no vacuum, salt spray test, which is more than 120 h.

3) The brushed aluminum plate can be bent or stamped directly to avoid complex surface treatment procedures, simplified production processes, and high efficiency.

4) Brushed aluminum sheet is light, the density of aluminum is 2.73 g / cm3, only 1/3 of stainless steel, has a lightweight advantage.

5) The brushed aluminum plate is relatively environmentally friendly. Recycled use will not cause waste of resources to the social environment, 0 formaldehyde.

During the drawing process, it is necessary to use the sandpaper by artificial application of sandpaper to solve it. This repeated scraping process is an indispensable part of production and processing. Second, when the film is treated, it is necessary to brussels treatment. The appearance looks more beautiful, and the film technology is also the focus of processing industrial production. Staff needs to take it seriously. Only a serious and responsible attitude can make every part of the brushed aluminum plate to the extreme.

Basic steps for making aluminum panels:

1) Aluminum and aluminum alloy sheet strips are supplied with a hot rolled state, annealing state, and various levels of soft state and various heat treatment states.

2) Aluminum plate preparations in hot rolling mainly include ingot quality inspection, hot, sawing, milling surface, aluminum and heating.

3) The cooling speed is very high during semi-continuous casting, the diffusion process in the solid phase is difficult, and the internal composition of the ingot is easy to form a chemical composition and tissue unevenness, such as crystalline segregation, etc.

4) When the surface of the ingot is analyzed, there are defects such as an analysis of the surface, residue, scars, and cracks, and the milling surface should be performed (see the non -ferrous metal alloy ingot gray mill surface). This is an important factor in ensuring the good surface quality of the finished product.

5) Hot rolling: The hot rolling of aluminum alloy ingots is a thick plate that provides cold rolling materials or directly produces hot rolling state.

6) The hot -rolled process system includes a secondary pressure, rolling temperature, rolling speed, and lubrication and cooling.

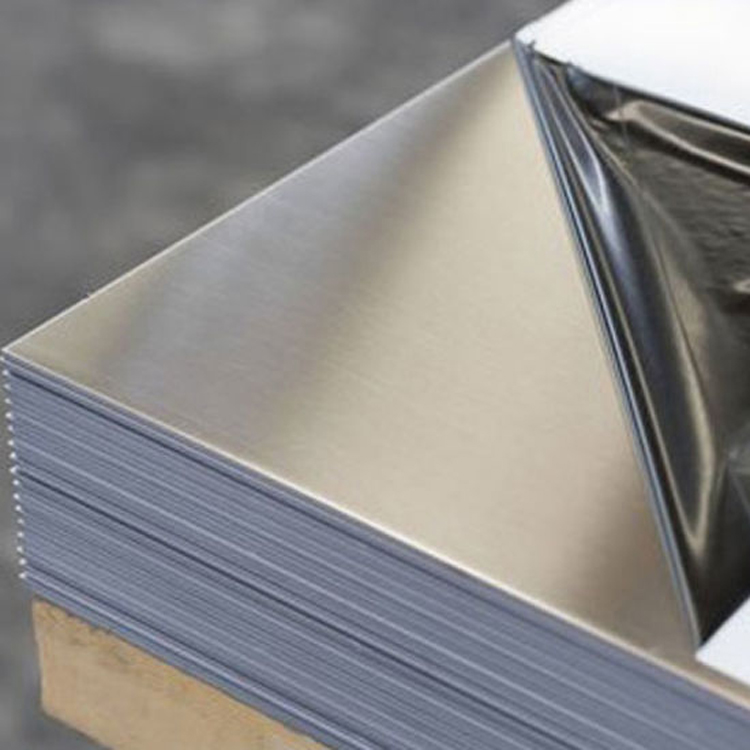

Alloy aluminum plate is added to various alloy elements during aluminum plate processing (main alloy elements with copper, silicon, magnesium, zinc, manganese, secondary alloy element with nickel, iron, titanium, chromium, lithium, etc.) to improve the mechanics of aluminum plates. Performance and chemical indicators. Alloy aluminum plates have some special properties that do not have pure aluminum plates, widely used in special environments, such as ships, refrigerators, molds, aerospace equipment and other aspects.

1) Durability and corrosion resistance

Use PVDF fluorocarbon spray, or spray static powder to ensure that aging and corrosion resistance is excellent.

2) Light weight and high pressure resistance

3.0mm thick aluminum plate weighs 8kg per square meter plate, and the pressure resistance strength is 100 ~ 280N/m.

3) A variety of anti -plating layers and various colors

Excellent electrostatic induction spraying technically promotes the contradiction between paint and aluminum plate adhesion, and there are diverse colors. The requirements for selecting indoor spaces are large, and the requirements of architecture are required.

4) Easy processing

Select the first processing of painting technology, aluminum plates can be processed into a variety of geometric shapes such as flat maps, arcs, and curved surfaces to meet the complicated shape requirements of engineering buildings.

5) Equipment engineering construction, convenient and convenient

The aluminum plates are all equipped on the spot after the processing plants are processed according to the processing of the order diagram. Therefore, the quality of the project is very high, especially in response to some irregular graphics. When the two -dimensional slope shape, it also mainly shows this characteristic.

6) It is not easy to pollute, which is conducive to cleaning and maintenance

The non -stickability of fluorine building coating film makes it difficult to adhere to pollution substances on the surface and has excellent self -cleaning.

7) Recycled and reused, which is beneficial to environmental protection

Aluminum plates are different from decorative design materials such as mezzanine glass, stone, porcelain, aluminum soul board and other decorative design materials. It can be recycled and recycled and depreciated.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...