What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

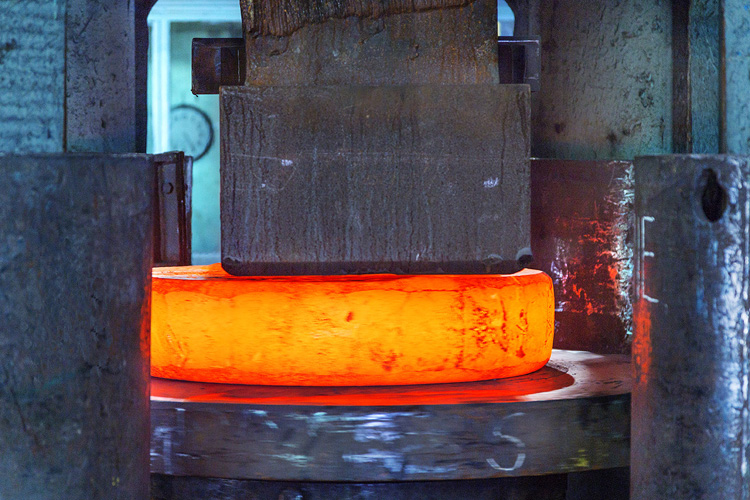

What is the difference between 201 st...The "white dot" in forging is a common product of metallurgy and forging. The defect is found in the forging parts in the smelting of materials. The "white dot" is generally distributed in the form of the forged parts in the form of a group. It is a big, how to accurately determine the "white dot" in the forging parts and take appropriate post -forging heat treatment processes to eliminate this defect is an important quality guarantee measure for forging enterprises in the production of forging.

"White Point" is a common dense defect in forging. How to correctly determine the "white dot" of the forging parts with ultrasonic detection. This is the starting point of our technical exploration. Through the characteristics of defective wave types found in ultrasonic exploration Analysis, combined with the observation and interruption method of the forging defects to prove the defect nature, the wave -type characteristics of the ultrasonic defect are accurately determined by the forging "white dot". At the same time Measures eliminate "white dots".

We have made a comprehensive exploration of this phenomenon, and the idea of solving the problem is as follows:

① Preliminary positioning of forging defects with ultrasonic probe.

② Single samples perpendicular to the vertical of the mold on the defect area.

③ Use magnetic detecting to make a imaginary positioning of the defects found in the sample slicing slice.

④ Observe the samples and interrupted port observation of the defects of magnetic probe seeing the image positioning.

⑤ Use gold phase observation to perform qualitative analysis of defects.

⑥ Put forward process solutions on the basis of fixed analysis.

⑦ Use ultrasound to explore unqualified mold blanks implementation process test.

⑧ Use the new process to process the mold blanks and then use ultrasonic to explore the re -examination.

Here are the actual operation process of this process exploration:

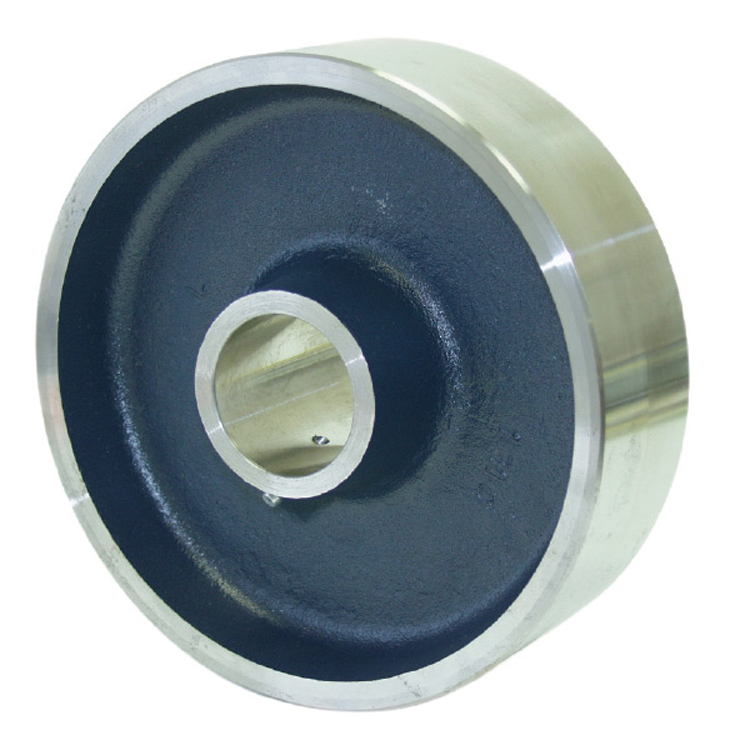

Forging size: 2000 × 400 × 185

Forging material: 5CRNIMO

Steel ingot type: 2.5T Sic -square ingot (450 × 450 × 750)

Forging process: The heating temperature is 1180 ° C, the forging temperature is 1150 ° C, and the two fires are naturally slow.

After forging: 880 ° C for 6-8 hours, the furnace is cold to less than 500 ° C.

For the sampling of the defective forging, the slices are observed directly with the naked eye after the slicing.

Since the slice is directly grinded, it cannot be found by the naked eye and cannot be found in the naked eye. Therefore, the measured measures for magnetic detection fluorescent appearance positioning are observed and determined. The distribution of defects, at the same time, cut into gold phase observation samples and interrupt port observation samples for the defects of magnetic probe visual positioning. After the magnetic detection defect is positioned, it will be cut and observed with the interruption.

After making the fracture sensitive gap in the above two samples, the interruption test is performed. From the section of the two fracture samples, you can clearly see the dense defects inside the forgedness discovered by the ultrasound and the magnetic exploration White dot.

Take 15 × 15 gold phase samples at the defect found in the magnetic probe. After the sample is grinded by 4%nitrate alcohol, the gold affection is observed under 100 times, 500 times, and 1000 times optical microscope.

From the introduction of relevant information, the formation of "white dots" in forging is mainly due to excessive hydrogen content in the raw materials (generally required the H content in the steel ≤ 2.1 ppm), and the hydrogen atom gathers at room temperature in the form of hydrogen molecules at the crystal world. Due to the growth of its volume, the crystal boundary was "breaking" to form a crystal crack, and the test of our company also completely verified the above statement. Therefore, the cracks are completely oxidized. This crack should be re -"welded" in the action of external forces. According to the characteristics of the "white dot", we are Re -forging, at the same time, formulate special post -forging heat treatment processes to remove the hydrogen content in the raw material, and the forging parts after the processing are still scanned with 24DB attenitance. It is found that the original "white dot" in the forge has completely eliminated.

The dense defects presented in ultrasonic detection are diverse. "White dot" is one of the basic forms of the internal dense defects of the forging. The amount of quantity is not large, but the actual area of the "white dot" from the fracture can be seen that the actual area of "white dot" is far greater than the calculated value calculated. This shows that the "white dot" is very harmful in the forging parts, but from this book On the other hand, "White Dot" is a non -oxidized crystal crack because of the "white dot", after re -forging "welding" and special exhaust hydrogen removal processes, " White dots "are eliminated.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...