What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

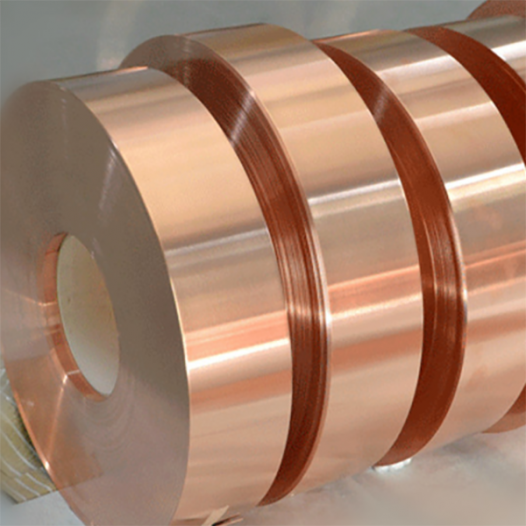

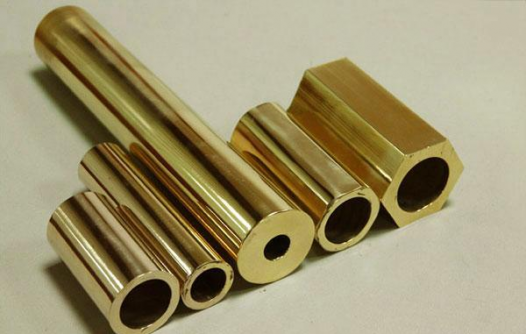

What is the difference between 201 st...Brass tube: one of the colored metal tubes, is suppressed and drawn seamless tubes. The copper tube has a strong and corrosion-resistant characteristic, which has become the first choice for modern contractors in all residential commercial housing tap water pipes, heating and cooling pipeline installations.

Characteristics of brass tube: brass tube is light in weight, good in thermal conductivity and high in low temperature strength. Commonly used in the manufacture of heat exchange equipment (such as condensers, etc.). It is also used to assemble cryogenic pipelines in oxygen production equipment. Copper pipes with small diameters are often used to transport liquids under pressure (such as lubrication systems, oil pressure systems, etc.) and pressure measuring pipes used as instruments. Brass pipes are strong and corrosion resistant. Brass pipes are the best water supply pipes.

Density of brass tube: The density of processed brass tube is 8.5-8.8 (g/cm3), and the density of cast brass is 7.7-8.55 (g/cm3).

Points to note when welding brass pipes:

1. During the welding process, always keep the flame covering the contact to prevent air from entering;

2. The flux will be soldered dry, the moisture will evaporate at 100 ℃, and the flux will become milky white;

3. The flux will foam at 316℃;

4. The flux becomes paste at 427℃;

5. The flux becomes fluid at 593°C, which is close to the brazing temperature;

6. Solder containing 35%-40% silver melts at 604°C and flows at 618°C;

7. Note that the two workpieces to be welded must be heated with a welding torch;

8. The color of the flame can be used to observe whether the temperature is suitable. When the temperature reaches the brazing temperature, the flame will appear green, and when it reaches the silver welding temperature, the green flame indicates that the temperature is suitable;

9. The copper pipe and the steel pipe are welded to each other, and the copper pipe must be heated first (because the copper pipe conducts heat quickly and requires a lot of heat);

10. During the brazing process, the welding torch should not stop at one point all the time, it can be moved in a figure 8 shape;

11. It is recommended to use a large welding torch, so that a soft flame can be used to obtain large heat without overpressure or "blowing", and it is best to have a slight plume on the inner conical flame.

Polishing of brass tubes: Brass tubes are not bright when they are first produced, which requires certain polishing treatments. There are many ways to polish brass tubes, and there are two commonly used ones.

1. Chemical polishing: usually, the brass tube is put into a certain amount of acid solution (nitric acid, hydrochloric acid, sulfuric acid). By chemically reacting the brass tube with acid (acid corrodes copper), the acid proportion can be modulated according to the desired brightness of the brass tube.

2. Physical polishing: It is relatively simple, that is, put the brass tube into a special polishing machine, and use machine grinding for polishing.

Identification of fake and inferior brass tubes:

1. Fake and inferior brass tubes are easy to fold. Folds are various fold lines formed on the surface of the brass tube, and this defect often runs through the longitudinal direction of the entire product. The reason for the folds is that the counterfeit and inferior manufacturers pursue high efficiency, and the reduction amount is too large, resulting in ears, and folding occurs during the next rolling. .

2. The appearance of fake and inferior brass pipes often has a pockmarked surface. The pitted surface is a defect of irregular unevenness on the surface of the brass tube due to serious wear of the rolling groove. Because the manufacturers of fake and inferior brass pipes want to pursue profits, it is often the case that the rolling groove rolling exceeds the standard.

3. The surface of the fake and inferior brass tube is prone to scarring. There are two reasons:

(1) The material of the fake and inferior brass tube is uneven and there are many impurities.

(2) The guide equipment of the fake and inferior material manufacturers is simple and easy to stick to the steel. These impurities are prone to scarring after biting the roll.

4, the surface of the fake material is easy to produce cracks, because its blank is a hull, the earth is large, and the hull is in the process of cooling because of the heat stress, the crack is generated, and there is crack after rolling.

5, the fake and shoddy brass tube is easy to scratch, because the fake-only manufacturer is simple, easy to generate burrs, scratching the surface of the brass tube. Depth scratches to reduce the strength of the brass tube.

6, the fake and bronze tube has no metal gloss, which is light red or the color of the pig iron, which has two points:

(1) Its billet is a hull.

(2) The temperature of the fake material rolling is not measured, and their steel temperature is visually measured, so that the austenite area cannot be rolled, the function of the brass tube is naturally unable to meet the standard.

7, the transverse thick wall seamless tube is thin and low, often the phenomenon of dissatisfaction, the manufacturer is a large negative general, the amount of pressure is large, the iron type is small, hole type Dissatisfaction.

8, the cross section of the fake brass tube is elliptical because the manufacturer is large in order to save material, and the pressure below the finished roller is large, and the strength of this rebar is greatly reduced, and it does not meet the shape of the thread steel shape. Scale.

9, the ingredients of the high quality brass tube are uniform, the tonnage of the cold shear is high, and the cutting end face is smooth and tidy, because the fake material is poor, the cutting end surface often has a phenomenon, that is, the unevenness, no metal gloss .

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...