What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...Aluminum tube is a circular, hollow aluminum tube, can provide a variety of diameters and thicknesses; it is a lightweight, corrosive metal, typically used as a material for pipelines and construction applications, more suitable for structural applications and high pressure fluid flow.Aluminum is used when high corrosion is required. It can be alloyed with zinc, copper, silicon, manganese and other metal to improve its strength and hardness.

Aluminum tubes have huge automotive and aerospace purposes to hit the ball, framework and other construction applications. The aluminum tube is firm and durable, with excellent strength ratio and high corrosion resistance.

Aluminium tubes and pipes are primarily made through a method known as extrusion. The raw aluminium materials are cut down and heated to a specified temperature and pushed through an extrusion die at high pressure, before being cooled down, stretched and cut to size, before any additional heat or other treatment.

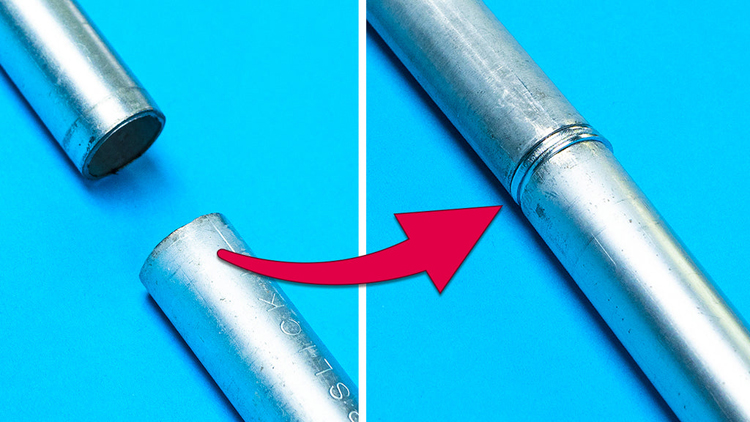

You can bend all aluminium tubing sizes as long as you carefully consider the thickness to bend ratio. To bend aluminium tube, the first step is to choose the correct thickness and alloy to ensure it can handle forming without cracking or damage. You can use a manual or hydraulic pipe bender as well as a bend die if you would like to create multiple uniform bends. Bend your aluminium tubing slowly for an even bend.

You can cut aluminium tube or aluminium pipe with a hacksaw, a circular saw, a mitre saw or a band saw, as long as you use the correct blade. A pipe cutter is commonly used to cut aluminium pipe without too large a diameter. It’s important to use lubrication and work slowly to avoid damage or bending.

To weld aluminium tube, you follow the same process as any other aluminium welding. The method that you use (MIG, TIG, Arc) will depend on the size and thickness of your aluminium pipe or round tube product, as well as your desired finish and application.

Aluminium tube can be soldered but requires a higher level of heat to other metals, as well as specialist flux, solder, equipment and the technique to perform your soldering quickly.

You can recycle aluminium tubing like any other aluminium products. It is one of the most recyclable and therefore environmentally friendly metals available.

Aluminium tubing and rods are popularly used to repair or strengthen and can be used both indoors and outdoors. They have a variety of purposes and are light, as well as strong, so they’re particularly easy to work with. They’re also resistant to moisture and other weather elements, making them a safe and simple option for a range of building tasks.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...