What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...The titanium plating process for aluminum profiles belongs to the coating technology. It adds pre-plating and electroplating process steps on the basis of the conventional titanium plating process. The aluminum profile process is to place the activated plated parts in an aqueous solution of salt and hydrochloric acid for chemical treatment; electroplating The components of the plating solution in the process include nickel sulfate, nickel chloride, boric acid, sodium lauryl sulfate, saccharin, and brightener. This process has the advantages of simplicity, practicality, and good effect. The layer hardness is HV≈1500, and it is 150 times more wear-resistant than plated 22K gold under the same conditions.

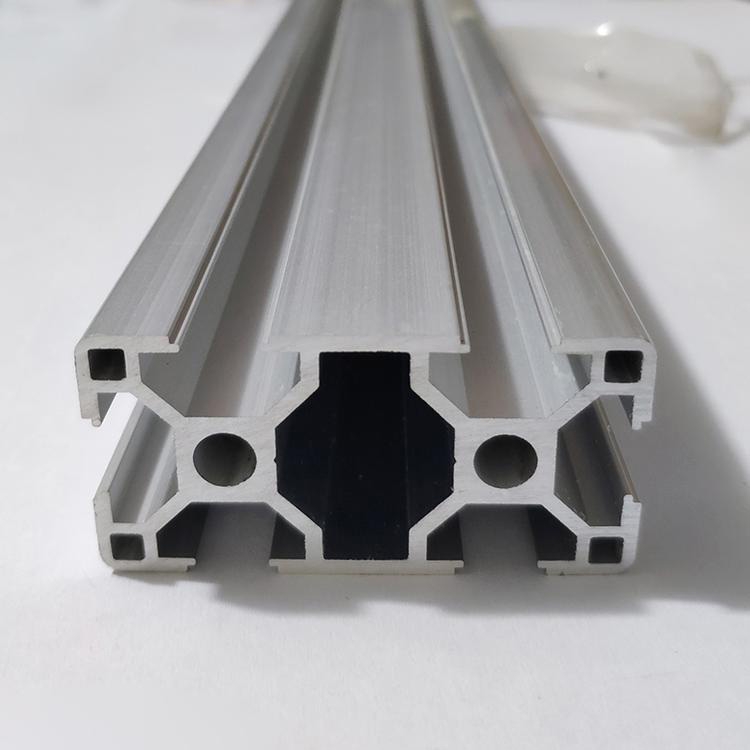

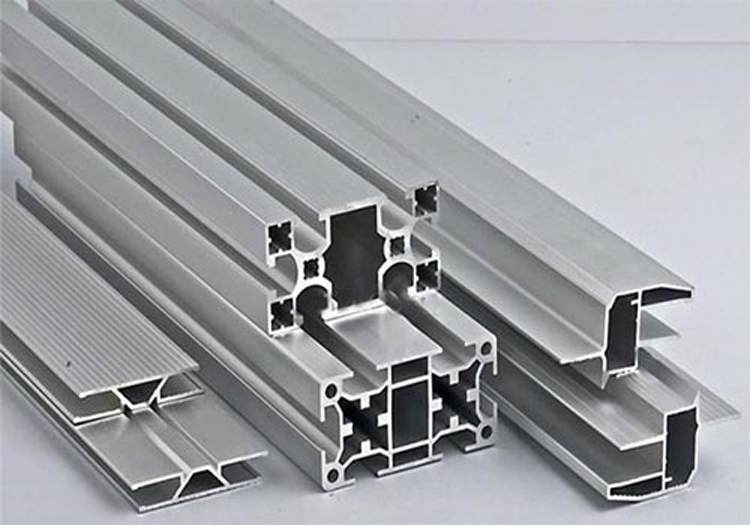

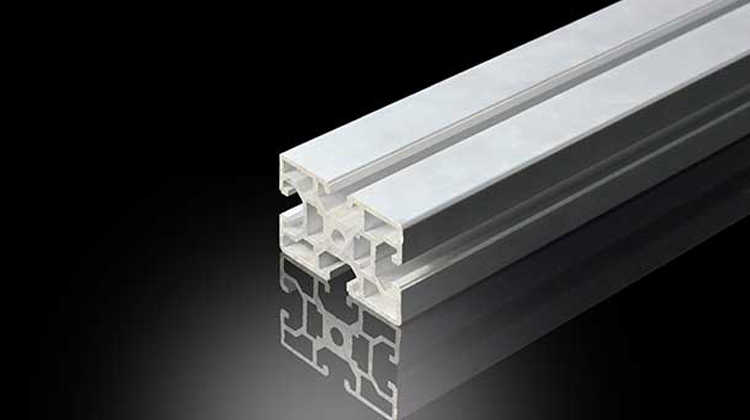

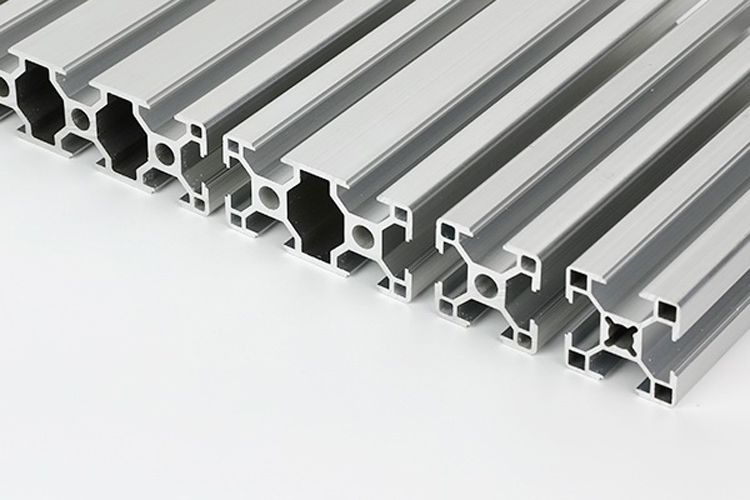

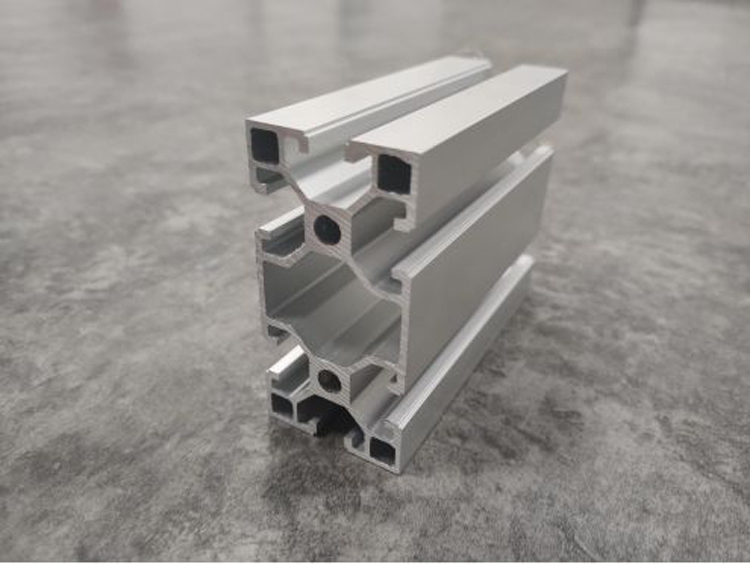

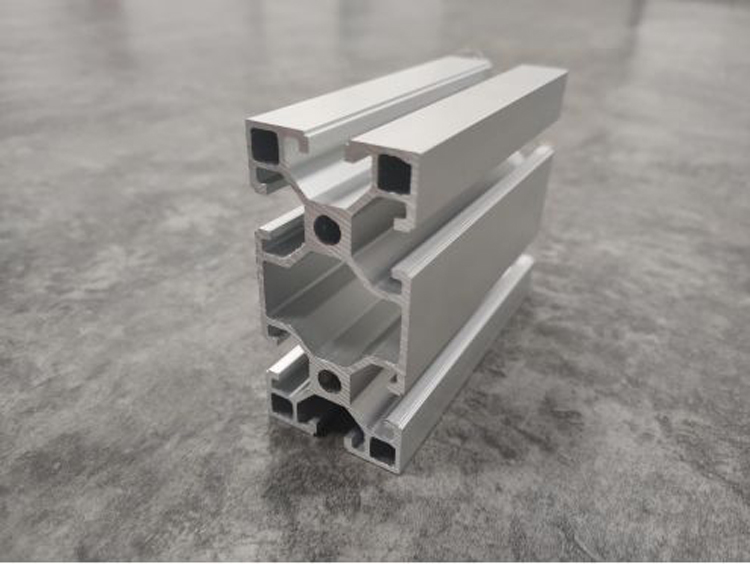

Industrial aluminum profiles are also called industrial aluminum extrusions and industrial aluminum alloy profiles. In recent years, the consumption has increased year by year and maintained a rapid growth rate. Industrial aluminum profiles are mainly used in industrial production and manufacturing. They are alloy materials with aluminum as the main component. Aluminum rods are hot-melted and extruded to obtain aluminum materials with different cross-sectional shapes. The mechanical properties and application fields of the industrial aluminum profiles are also different.

After the surface of the industrial aluminum profile is oxidized, it has a very beautiful appearance and is resistant to dirt. Once it is coated with oil, it is very easy to clean. When assembling into a product, different specifications of profiles are used according to different bearing loads, and matching aluminum profile accessories are used without welding. More environmentally friendly, and installation, disassembly, light and easy to carry, very convenient to move.

First, first, from the application of aluminum profiles, aluminum profiles have an extrusion process and higher aluminum mechanical equipment process performance, excellent heat transfer performance is relatively high. Applicable equipment architecture, support frame, door, industrial production automation machinery, processing plant and company office operators, freight boxes, warehousing shelves, human graphics, etc. Aluminum profiles should basically contain the industrial aluminum production and manufacturing industries, and the category is not necessarily common.

Second, everyone from the application of aluminum profiles, the construction of aluminum profiles, integration and intelligence, no more integrated design programs and production and processing, can quickly architectualization of the ideal chemical equipment jacket, apply aluminum profile zero Accessories, such as bolt nuts, corners, etc. can be easily assembled. The aluminum profile is not only the bolt nut joint, but also a hole tapping, which can make the product more secure, and a variety of connection methods are also aluminum profiles according to different ways to use structures. Enhanced a lot of opportunities. The aluminum profile is more expandable, and the different T-concave tank design is designed, and the aluminum profile can be installed without disassembling the aluminum profile, and the modified machine is simple and convenient. This also greatly enhances the secondary application indoor space of aluminum profiles.

Third, the aluminum profile design is beautiful and very easy to use (Today's industrial-grade aluminum profile is silver-white air oxidation), lightweight and bending high, simple and beautiful surface is not paint. It is said that now is the era of face, the product is beautiful, the quality will be more, of course, not afraid of no sales market. For this reason, many people have gradually abandoned metal products, followed by aluminum profiles.

(1) 6063, 6063A, 6463A, 6060 industrial aluminum alloy profiles. In addition to widely used as construction doors and windows and curtain wall structures, there is a large number of indoor furniture, bathroom, radiators, lift waves, and general industrial pipes and bars.

(2) 6061,6068 Aluminum alloy industrial profiles. It is mainly used as a refrigerator, container floor, truck frame component, ship upper structure member, rail vehicle structure, large truck structure, and other mechanical structural members.

(3) 6106 aluminum alloy industrial profile. Widely used in various requirements of corrosion resistant tubes, wires and bars.

(4) 6106, 6101B Aluminum alloy industrial profile. Dedicated to the production of high-strength hue, various conductive body materials.

(5) 6005 aluminum alloy industrial profile. Mainly used as ladder, television antenna, television launcher, etc.

(6) 6005A aluminum alloy industrial profile. Used in high-speed trains, subway trains, light rails, double trains, luxury bus, light rail, double train, luxury bus, and large-scale shaped structural parts, important force components and large-scale materials for large vehicles Decorative part.

(7) 6351T6 aluminum alloy industrial profile. Many for highway traffic facilities extruded structural parts and gas supply, oil, water pipelines, etc.

(8) Other aluminum alloy industrial profiles. Such as 2024.7075, etc., high-strength aluminum alloy profiles, bars, and development, and intended to establish quenching furnaces and large-scale pulseing machines, to adapt to large quantities.

(1) The temperature is too low in industrial aluminum profile, the extrusion speed is too slow, the profile does not reach the solution temperature in the extruder, and no solid solution reinforcement is obtained.

Solution: Reasonably control the extrusion temperature and the extrusion speed, the profile is maintained above the extruder's outlet temperature or more;

(2) There is less fan in the export of industrial aluminum profiles and the air volume, resulting in slow cooling speed, can not reduce the industrial aluminum profile to 200 ° C below 200 ° C, so that the coarse silicide magnesium is prematurely cut, thereby reducing solid solution , Affecting the mechanical properties after heat treatment of the profile;

Solution: Enhanced air-cooled conditions, conditional plants can install atomized cooling devices, with the lowest requirements of 6063 alloy cooling gradient;

(3) The ingot is unqualified, the magnesium in the ingot, the silicon content can not reach the standard requirements;

Solution: Strengthen the quality management of ingots;

(4) The ingot is uniformized, so that the silicide magnesium from the ingot tissue cannot be re-dissolved in a short period of extrusion, causing solid solutions and affecting product performance;

Solution: Take a homogenization of ingots;

(5) Improper working process, hot air circulation is not smooth or the thermocouple mounting position is incorrect, resulting in insufficient aging or overemployment.

Solution: Reasonable determination of the aging process, properly install the thermocouple, correctly placed industrial aluminum profiles to ensure hot cycle.

(1) Profiles need to be processed: bolt link, built-in connecting parts link, bevel connector link, elastic fastener link.

(2) The profile does not require processing: angle link, corner tank link link, corner bracket link, etc.

These links can also be divided into internal connections and external connections. The internal connections are mainly: bolts link, angular tank connecting parts, built-in connectors, etc., external connections such as: corner link, angular bracket link, etc.

In fact, each link method has its own unique advantages and disadvantages, most mainly to consider actual use needs.

Aluminum profile producers, generally all five years of the industry, rich in manufacturing experience, have a very good masterpiece for the quality and characteristics of the product, will strongly recommend the right customer must, cost-effective Products, picking out the parts that are convenient and easy to use.

We must carry out marketing promotion on online customer service. This usually injured is everyone consumers. The wiring online customer service, most of them don't understand how to use it, just understand the price. How to use the customer's request; how to make the cost-effective high. Big; in a different type of connection method is. Ok; this kind of people can't .. response. Just understand strongly recommended. Deliveed aluminum profiles and. Delivered connection methods; this type of connection is cost fee. Less, but. Fee people's strength, the compressive strength. A looping method, aluminum profile is also a point Will not reflect, and will have a large inconvenience after the update transformation.

Industrial production of aluminum profiles are generally widely used, which is extremely practical. It is famous for assembled, environmental protection, saving time and effort. Industrial production aluminum profiles, specifications, suitable variety of mechanical equipment equipment applications; no electric welding welding, adjustment specifications, easy to structurally; standard tolerances, high surface smoothness, saving time and effort High production efficiency; surface is solved by anode oxidation, no painting, corrosion resistance, unique, can enhance product extra use value.

In the case of an industrial aluminum expertise, in the case of an industrial aluminum, it is necessary to follow the status, and the industrial aluminum purchased can be in a must.

Due to the use of industrial aluminum profiles, it can be assembled into various structural types by applying the principle of building blocks according to different needs, which simplifies the design, shortens the production cycle, and avoids complex structures, many parts, and large design workload. Series disadvantages.

Since the processing of the industrial aluminum profile structure requires only the material, the punching and rare bending, the processing is simple, the installation is avoided, avoiding the multi-process processing of the gold structure, making the production process greatly simplified. At the same time, it reduces the strength of a large number of hand-operated sheet metal labor, which improves production efficiency and easy to adopt automation production.

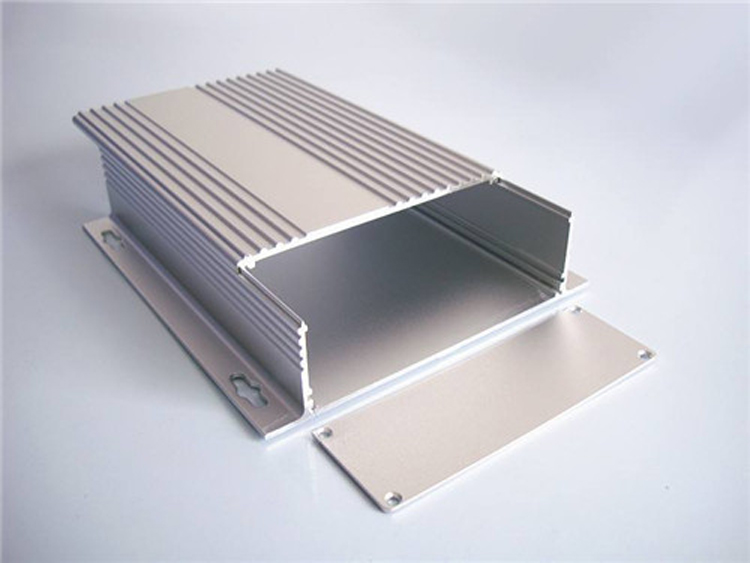

According to statistics, after the electronic instrument chassis is used by aluminum industry aluminum profiles, it is about 60% weight than the original sheet metal structure with black metal.

According to statistics, a desktop metal thin plate chassis requires approximately 40 monuped molds, while industrial aluminum profile structures. More than 20 departments

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...