What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

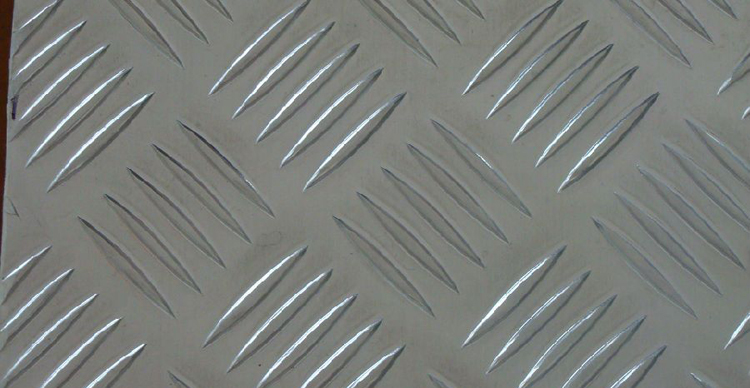

What is the difference between 201 st...Aluminum alloy embossed plate can also become aluminum embossed plate, which belongs to aluminum products with patterns formed on the surface after calendering on the basis of aluminum plate. It is widely used, mainly used in buildings, curtain walls, etc.

The embossed aluminum plate not only has the function of anti-skid, but also has the characteristics of light weight and oxidation resistance. With the increasing production technology, embossed aluminum sheet, as a high-quality high-tech material, will definitely be able to completely replace traditional steel and be more widely used in more fields. Embossed aluminum sheets are mainly used for anti-skid floors and other anti-skid floors in buildings, vehicles, ships, airplanes, etc.

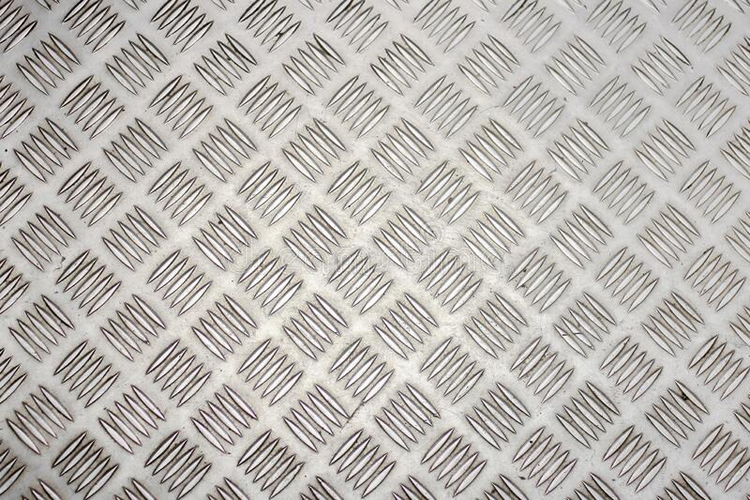

Aluminum alloy embossed plates can be divided into:

aluminum alloy embossed plate processed with 1060 aluminum alloy plate as the plate base, can adapt to the ordinary environment, low price, and this pattern is often used in the outer packaging.

processed with 3003 as the main raw material, this kind of embossed aluminum sheet has become an anti-rust aluminum sheet, the strength is slightly higher than that of ordinary aluminum alloy embossed sheet, and it has a certain anti-rust performance.

It is processed from 5052 or 5083 series 5 aluminum sheet as raw material, which has good corrosion resistance, hardness and rust resistance. Usually used in special places, such as ships, carriages and other wet environments.

Thin plate: 0.15-2.0mm

Regular class: 2.0-6.0mm

Thick plate: 25-200mm

Ultra-thick plate: more than 200

The production process of embossed aluminum sheet is not simple. First of all, it is not very simple to make a regular pattern on an aluminum sheet. This means that there is another process in the process, which not only increases the investment of machinery and equipment, but also consumes more manpower and cost, and also has special use environments. Secondly, the pattern formed on the surface not only plays the role of decorative landscaping, but the anti-skid effect is the same as the clarity, anti-skid and grip of the tire.

There are many types of patterned aluminum sheets that can be used in different industries. First, ordinary aluminum alloy plates are processed into raw materials from ordinary 1060 aluminum plates. Relatively low production and processing costs, suitable for cold and vehicle floors in general conditions. Secondly, the aluminum-manganese alloy plate is made of aluminum and manganese. Alloy 3003 is processed from main raw materials, has certain strength and impact resistance, has certain rust and corrosion resistance, and is mainly used in railway carriages. Third, the aluminum-magnesium alloy sheet is 5052 or higher. Graded aluminum is machined with high strength and hardness, and is highly resistant to rust and corrosion, and can be used in marine and even aerospace industries.

Embossed aluminum plate is also a metal material, which requires scientific maintenance methods in daily use. First, when cleaning regularly, the stained surface should be cleaned with water or a corresponding detergent, and the residue of the stain will easily cause corrosion and deformation of the sheet; barrier to effectively prevent corrosion. On the other hand, it can beautify the decoration and help it better integrate into the environment of use.

With the increasing demand for aluminum sheets in various industries, the sheet itself is also undergoing continuous technological innovation. Embossed aluminum sheet is the product of this innovation, and its appearance gradually fades out of the market of traditional aluminum sheet and other sheets. Because it has many excellent features. However, any substance will cause corrosion and wear during use, and maintenance work must be strengthened to prolong the service life.

The requirements of aluminum panels in the production environment need to pay attention to ventilation. The guarantee of ventilation is very necessary. Pay attention to good ventilation quality. This is necessary for the quality assurance of the product. meet consumer requirements.

The requirements of the patterned aluminum plate in the production environment need to pay attention to the cleanliness and cleanliness in the production environment, and the quality of the product must be guaranteed. Pay attention to regular cleaning and pay attention to ensure the placement of the product. There will be no quality issues during this process.

The preparation of aluminum alloy pattern aluminum plate in the production environment also needs to pay attention to the protection requirements. The protection of protection is very necessary, and it is necessary to pay attention to the excellent quality of protection to ensure that the product is produced during processing without a lot of toxicity, which will As a result, the safety of the producer is affected.

It can be seen that the preparation of patterned aluminum plates in the production environment requires attention to these, and in terms of effects, the guarantee of product quality is very necessary.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...