What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...Many people can't tell the difference between magnesium alloy and aluminum alloy. Although they know that the two are different, what are the specific differences? changjin metal will explain it to you in detail! The density of magnesium is only 1.8g/cm3, which is the lighter among the three metals, which also makes magnesium alloy 30% lighter than aluminum alloy and 80% lighter than steel. At the same time, it has an excellent strength/weight ratio, with a yield strength of 160 MPa and a tensile strength of 240 MPa, making it widely used in electronic products, aerospace and other fields that are sensitive to quality and strength.

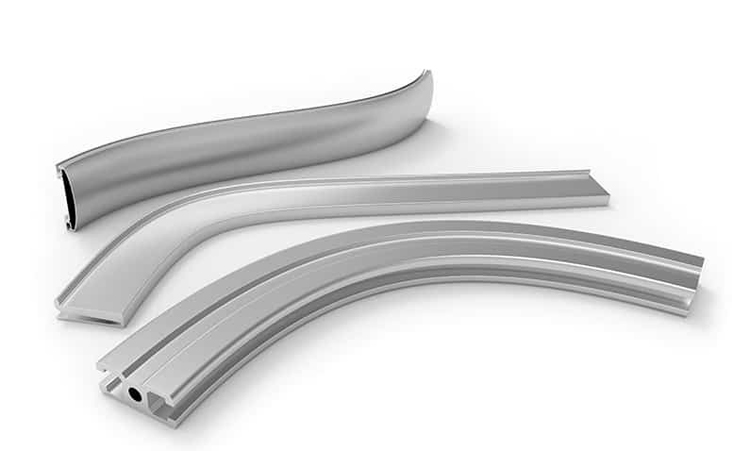

On the premise of maintaining a good structure, magnesium alloys allow the wall thickness of castings to be as low as 0.6 mm, which is impossible for plastics and aluminum alloys. Magnesium alloys are easy to die-cast and have better machinability. Suitable for mass production. Magnesium metal itself has excellent shock absorption performance, which can absorb a large amount of vibration and noise, so it is very suitable for the backplane of LCD display.

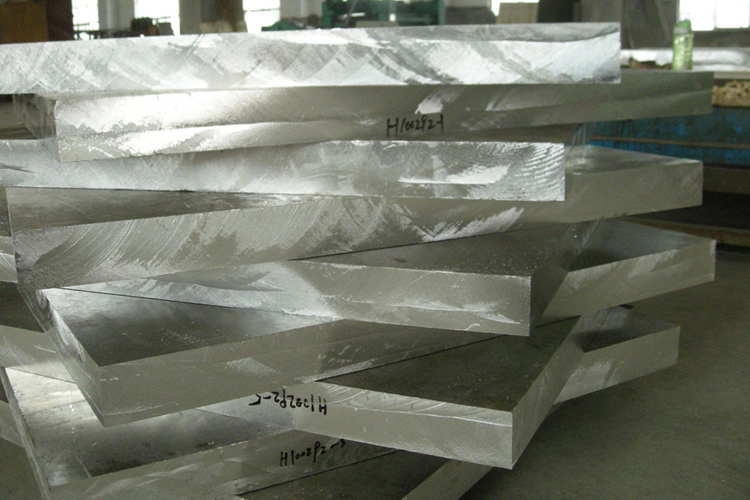

Aluminum alloy is a general term for a series of aluminum-based alloys. The main metal elements are copper, silicon, magnesium, zinc and so on. Aluminum alloys have low density, but their specific strength is close to that of high-quality steel, second only to alloys. Good plasticity, can be processed into various profiles. Corrosion resistance is outstanding.

Aluminum alloys can be divided into deformed aluminum alloys and cast aluminum alloys according to processing methods. Deformed aluminum alloys can be divided into non-heat-treatable aluminum alloys and heat-treatable aluminum alloys. Heat treatment can help the alloy obtain better mechanical properties, physical properties and corrosion resistance. The cast aluminum alloy can be divided into aluminum-silicon alloy, aluminum-copper alloy, aluminum-magnesium alloy and aluminum-zinc alloy according to the metal composition.

Compared with magnesium alloy, there is not much difference between aluminum alloy and magnesium alloy, but the density of aluminum alloy is slightly inferior and the viscosity is stronger. However, compared with magnesium alloys, aluminum alloys can be heat treated and have better welding performance.

The difference between the two is as follows:

(1) The tensile strength is different.

The strength of the frame made of the same volume of magnesium alloy material is not as good as that of the aluminum alloy. To achieve the strength of the frame, the thickness of the material and the diameter of the tube must be increased. Therefore, there is no advantage in comparing the magnesium alloy with the aluminum alloy from the perspective of weight.

(2) The fatigue resistance is different.

Taking the frame as an example, the durability of the frame made of magnesium alloy material of the same volume is worse than that of the aluminum alloy frame. It is also a fatal disadvantage of magnesium alloys.

As the number of rides increases, the number of times of stress is also higher, and the strength will be significantly reduced, and even the life of the frame does not exceed 2-3 years, so professional riders rarely use magnesium alloy frames. If they are used in competitions, It is also calculated that the mileage is replaced by discarding.

(3) The oxidizing properties of metals are different.

The periodic table of elements clearly shows that magnesium alloys are more susceptible to oxidation and corrosion than aluminum alloys.

(4) The manufacturing cost is different.

Because magnesium alloy is an active metal, the manufacturing equipment and environment have higher requirements, resulting in high manufacturing costs, and the cost performance of the produced bicycle frame is far less than that of the aluminum alloy frame.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...