What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

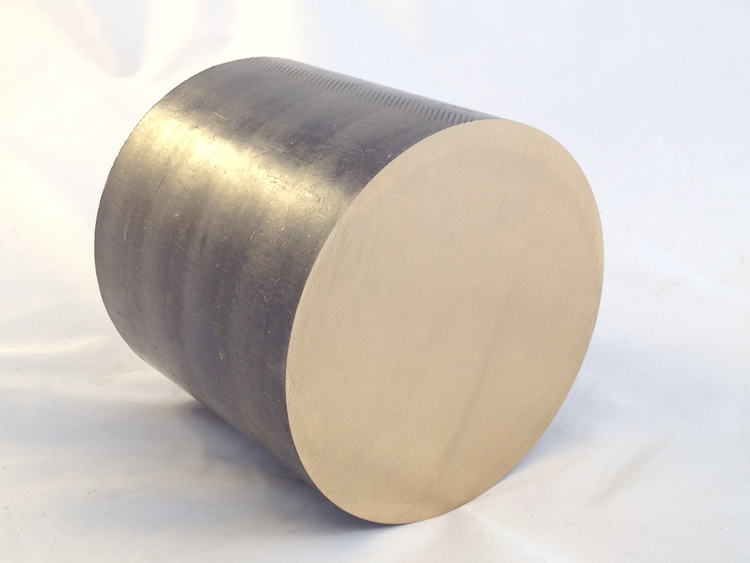

What is the difference between 201 st...Tin bronze is the metal alloy with the longest history of human smelting. It can be traced back to more than 5,000 years ago. The earliest tin bronze was generally used for making living utensils, sacrificial items and weapons. It is wear-resistant, has good mechanical properties and process properties, and can be welded and brazed well, and does not produce sparks when impacted, so it is gradually used as mechanical parts.

(1) Bronze with tin as the main alloying element. The tin content is generally between 3 and 14%, and it is mainly used to make elastic components and wear-resistant parts. The tin content of deformed tin bronze does not exceed 8%, and sometimes elements such as phosphorus, lead, and zinc are added. Phosphorus is a good deoxidizer and also improves fluidity and wear resistance. With high strength, corrosion resistance and excellent casting properties, it has been widely used in various industrial sectors for a long time.

(2) Bronze containing 3% to 14% tin, in addition, phosphorus, zinc, lead and other elements are often added. It is the earliest alloy used by mankind and has a history of about 4,000 years. It is corrosion-resistant, wear-resistant, has good mechanical properties and process properties, and can be welded and brazed well, and does not produce sparks when impacted. Divided into processed tin bronze and cast tin bronze. The tin content of tin bronze used for pressure processing is less than 6% to 7%, and the tin content of cast tin bronze is 10% to 14%.

(3) Tin bronze is a non-ferrous metal alloy with the smallest casting shrinkage rate, and can be used to produce castings with complex shapes, clear outlines and low air tightness requirements. Tin bronze is very resistant to corrosion in the atmosphere, sea water, fresh water and steam, and is widely used in steam boilers and marine ship parts. Phosphorus-containing tin bronze has good mechanical properties and can be used as wear-resistant parts and elastic parts of high-precision machine tools. Lead-containing tin bronze is often used as wear parts and sliding bearings. Zinc-tin bronze can be used for high air tightness castings.

Tin bronze plate is actually a bronze plate with tin as the main alloying element. Its tin content is generally around 3-14%, and it is mainly used to make elastic components and wear-resistant parts. The tin content of deformed tin bronze does not exceed 8%, and sometimes elements such as phosphorus, lead, and zinc are added. Phosphorus is a good deoxidizer and can also improve fluidity and wear resistance. Adding lead to tin bronze can improve machinability And wear resistance, adding zinc can improve casting properties.

Tin bronze plate has high mechanical properties, anti-wear properties and corrosion resistance, and is easy to cut, has good brazing and welding properties, small shrinkage coefficient, non-magnetic, and can be prepared by wire flame spraying and arc spraying to prepare bronze bushings, Shaft sleeves, diamagnetic components, etc., have high strength, corrosion resistance and excellent casting properties, so they are widely used in various industrial sectors.

In fact, copper is a non-ferrous metal that is closely related to human beings. It is widely used in electrical, light industry, machinery manufacturing, construction industry, national defense industry and other fields. The consumption of non-ferrous metal materials in my country is second only to aluminum. Tin bronze plate is a non-ferrous metal alloy with the smallest casting shrinkage, and is used to produce castings with complex shapes, clear outlines and low air tightness requirements.

Tin bronze plate is very corrosion-resistant in the atmosphere, sea water, fresh water and steam, and is widely used in steam boilers and marine ship parts. Phosphorus-containing tin bronze has good mechanical properties and can be used as wear-resistant parts and elasticity of high-precision machine tools Parts, lead-containing tin bronze is often used as wear-resistant parts and sliding bearings, and zinc-containing tin bronze can be used for high air tightness castings.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...