What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

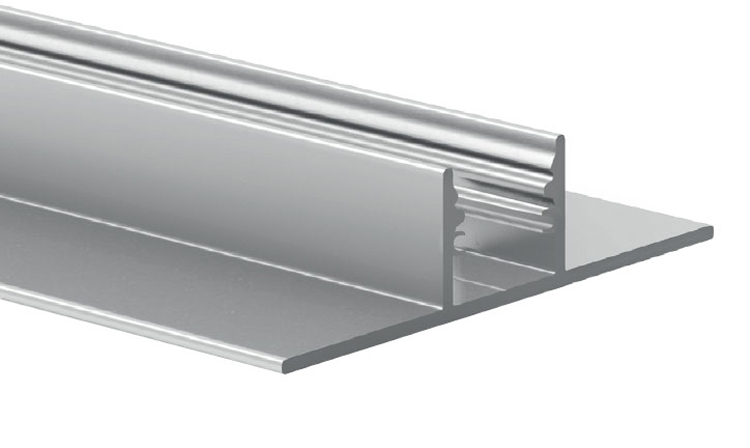

What is the difference between 201 st...After anodizing processing of aluminum alloy, a layer of oxide film which is anti-oxidation, anti-rust, anti-corrosion and wear-resistant will be formed, and the performance of this oxide film in the natural ecological environment is very stable, which can protect the surface safety of aluminum alloy products. Moreover, the outer layer of the anodized film of aluminum is porous, and it is easy to absorb dyes and colored substances, so it can be dyed and improve its decorative properties. After the oxide film is sealed with hot water, high temperature steam or nickel salt, its corrosion resistance and wear resistance can be further improved.

At present, the defects of aluminum profile coloring are generally in the following situations: light color, color difference, no coloring, white spots, dew whiteness, dyeing and blooming, color escape, etc. How to solve this kind of problem to ensure that the color difference of each batch of products is consistent?

This requires our enterprise technicians to study and prevent the electrolytic coloring surface treatment of aluminum profiles. The following changjin metal will explain the causes and treatment methods of light color and color difference caused by anodization of aluminum profiles:

1. The thickness of the oxide film is uneven. The possible reason is that the temperature and concentration of the anodizing bath liquid are uneven. At this time, the bath liquid should be stirred with compressed air to solve such problems.

2. The temperature or concentration of dye liquor is uneven. Introduce a stirring process and increase the number of stirrings at the same time.

3. The dyeing speed is too fast. The bottom of the workpiece enters the dye solution first and then leaves the dye solution, so the bottom is easy to dye deeply. The solution is to dilute the dye and prolong the dyeing time appropriately.

4. Poor electrical conductivity. It may be caused by the loose hanger. Pay attention to hang it tightly to avoid such problems.

5. If the dye is too dilute, you can add dye to increase the concentration.

6. The temperature of the dye liquor is too low. The dye liquor can be heated to below 60℃.

7. Improper dissolving of dyes, or floating of insoluble dyes, it is easy to produce color difference at this time. The solution is to improve dye dissolution.

Also note: the temperature during the anodizing process of aluminum profiles also has a significant effect on the properties of the oxide film: if the temperature is too high, the wear resistance and corrosion resistance of the oxide film will decrease, and the film formation will be difficult; if the temperature is too low, the transparency of the film layer will decrease, and the coloring Poor performance, enhanced brittleness, easy to crack.

In the treatment of aluminum alloy anodizing, the surface can be sprayed with various colors. In addition, anodizing in industrial aluminum profiles has the following characteristics:

1. High hardness. The anodic oxide film not only has high hardness, but also has good wear resistance. The multi-layer oxide film on the surface has the ability to absorb lubricating oil, which can improve the wear resistance of the surface.

2. High corrosion resistance. Because the oxide film itself has high chemical stability, the corrosion resistance of the oxide film after sealing treatment is generally improved.

3. Strong heat resistance. The anodized aluminum alloy is more heat-resistant than pure aluminum. The ordinary pure aluminum has a temperature resistance of 660 degrees, and the anodized aluminum alloy can withstand a temperature of about 1500 degrees.

4. Functionality. The anodized film is porous, and by depositing functional particles in the micropores, various functional materials can be obtained. Therefore, the aluminum alloy after anodization of aluminum alloys continues to expand its advantages and be used in all walks of life.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...