What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...

Cast iron means that the total number of cast iron-carbon alloys containing 2% to 6.67% is usually formed by smelt by cast iron, scrap, iron alloy, etc. in different ratios.

The main elements are removed from iron, and there are silicon, manganese and small amounts of phosphorus and sulfur and other elements. It is to re-rehydrate the pig iron (sometimes steel steel), and add iron alloy, scrap, and refrigerate iron to adjust the ingredient.

The reason why cast iron will have such a large number of extensive uses, mainly because of its excellent liquidity, and it is easy to cast into a variety of complex forms. The higher the content of carbon, the better the flow characteristics in the casting process. Carbon appears in two forms of graphite and iron carbide here.

The sewer lid is a part of our daily living environment, and some will pay attention to them. The lid of the sewer is made of cast iron. The presence of graphite in cast iron makes the sewer cover has excellent wear resistance. Rust usually only appears in the most surface, so it is usually polished. Although, in the casting process, there is still a measures to prevent rust, that is, a layer of asphalt coating is added to the surface of the casting, and the asphalt penetrates into the fine hole of the surface of the cast iron, thereby acting.

Material characteristics: excellent liquidity, low cost, good wear resistance, low-coagulation shrinkage, very crisp, high compression strength, good machiningability.

Typical use: Cast iron has had a history of hundreds of years, involving architecture, bridges, engineering components, home, and kitchen utensils.

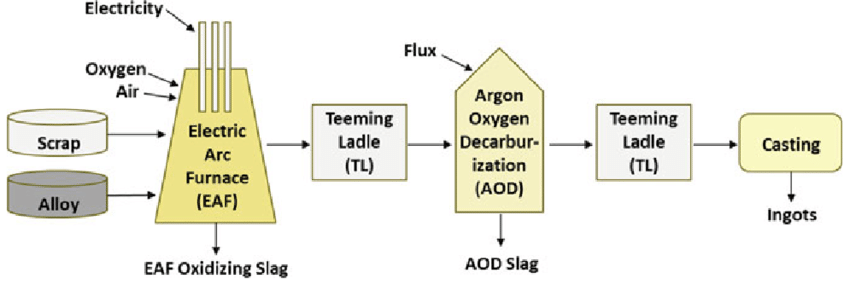

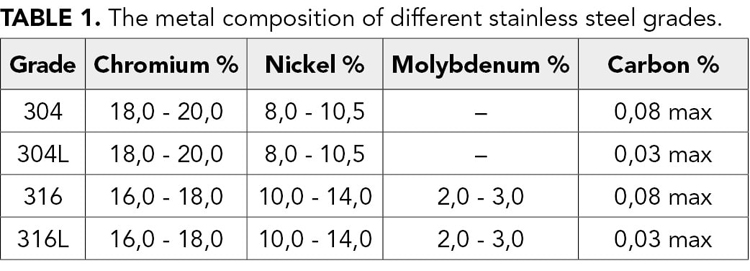

Stainless steel is alloyed in steel into chromium, nickel, and other metal elements. The non-rust-rusty character is from the ingredients of chromium in the alloy, and chromium forms a firm, self-repair, and has a self-repairable chromium oxide film in the surface of the alloy. This film is invisible. The ratio of stainless steel and nickel we will generally be included in 18:10. The term "stainless steel" is more than just just a stainless steel, but a good performance of more than 100 industrial stainless steels, each stainless steel developed has a good performance in its specific application.

At the beginning of the 20th century, stainless steel was introduced into the product design area, and designers developed many new products around its tenacity and corrosion resistance, involving many areas that have never been involved before. This series of design tries are very revolutionary: such as, the equipment that can be used again after disinfection first appears in the medical industry.

Material characteristics: health care, anti-corrosion, fine surface treatment, high rigidity, can be formed by various processing processes, more difficult to perform cold processing.

Typical use: In common primary color stainless steel, austenitic stainless steel is the most suitable coloring material, which can get a satisfactory color appearance and shape. Austenitic stainless steel is mainly used in decorative building materials, household items, industrial pipes, and building structures; martensite stainless steel is mainly used to make tools and turbine blades; ferritic stainless steel has anti-corrosion resistance, mainly used in durable washing machines and Boiler parts; composite stainless steel has stronger anti-corrosion performance, so it is often used in the erosive environment.

Zinc, the silver light is slightly blue gray, which is the most widely known non-ferrous metal after aluminum and copper. A statistical statistics from the US Minerals Bureau - an ordinary person consumes a total of 331 kg of zinc in his life. The melting point of zinc is very low, so it is also an ideal cast material.

Zinc-cast castings are very common in our daily life: the door brushed the material, faucet, electronic components, etc. below the surface of the watch, and the zinc has extremely high corrosion resistance, which makes it an additional most basic function, namely As the surface plating material of steel. In addition to these functions, zinc is synthesized with copper to synthesize alloy materials of brass. Its corrosion resistance is not only applied to steel surface plating - it also helps to enhance our human immune system.

Material characteristics: health care, anti-corrosion, excellent castability, excellent corrosion resistance, high strength, high hardness, cheap, low melting point, creep, easy to form alloys with other metals, health care, normal temperature Fragile, 100 degrees Celsius has ductility.

Typical use: Electronic product components. Zinc is one of the formation of bronze alloy materials. Zinc also has the characteristics of cleaning and corrosion resistance. In addition, zinc is also applied to shutter devices in roof materials, photo engraving dishes, mobile phone antennas, and cameras.

Aluminum, this slightly blue-ray white metal is only considered to be a baby in a metal material. Aluminum has been named after the 18th century and was named. Unlike other metal elements, aluminum is not present in nature in the form of a direct metal element, but refined from an aluminum oxide containing 50% alumina (also known as alumina). Aluminum exists in minerals in this form is also one of the most abundant metal elements.

When the aluminum is earliest, it is not immediately applied to people's lives. Later, a number of new products for their unique features and features gradually came out, this high-tech material has gradually possessed more and more broad markets. Although aluminum has a relatively short application history, the production of aluminum products on the market is far more than the sum of other non-ferrous metals.

Material characteristics: flexible plastic, easy to make alloy, high strength - weight ratio, excellent corrosion resistance, easy to conduct electrically conductive, can be recycled.

Typical use: vehicle skeleton, aerial parts, kitchen utensils, packaging, and furniture. Aluminum is often used to reinforce some large architectural structures, such as the statues of the love gods on the Picadili Square, London, and the top of the New York Chrysler Motor Building, all have aluminum reinforced materials.

Magnesium is an extremely important non-ferrous metal, which is light than aluminum, which can make high-strength alloys with high strength with other metals. The magnesium alloy has a specific gravity, higher than the strength, and has good thermal conductivity, and good damping The earthquake and electromagnetic shielding properties, easy to process, easy to recover, and so on. However, for a long time, due to expensive and technical restrictions, only small amounts of magnesium and magnesium alloy are applied to aviation, aerospace and military industries, and thus known as "noble metal." Today, magnesium is the third large metal engineering material after steel and aluminum, is widely used in aerospace, automotive, electronic, mobile communications, metallurgical fields. It can be expected that the importance of metal magnesium in the future is greater due to the increase in metal production costs.

The specific gravity of magnesium alloy is 68% of the aluminum alloy, 27% of the zinc alloy, 23% of the steel, commonly used in automotive parts, 3C product housing, building materials, etc. Most ultra-thin laptops and mobile phone case are made of magnesium alloys. Since the last century, human beings have a masonry, and there is still a loveless love. Although plastic products can form metal appearance, but their gloss, hardness, temperature, texture still have a gap between metal. The magnesium alloy is a new type of metal raw material to give people a high-tech experience.

The corrosion resistance of the magnesium alloy is 8 times the carbon steel, 4 times the aluminum alloy, more than 10 times the plastic, and the anti-corrosion ability is the best in alloys. Commonly used magnesium alloys have non-flammable, especially in the motorcycle parts and building materials, can avoid instantaneous combustion. Magnesium reserves in the crust of reserves, most of the magnesium feedstocks are refined in the sea water, so its resources are stable.

Material characteristics: lightweight structure, high rigidity, impact, excellent corrosion resistance, good thermal conductivity and electromagnetic shielding, good non-combustible, poor heat resistance, easy to recover.

Typical use: Widely used in aerospace, automotive, electronics, mobile communications, metallurgical fields.

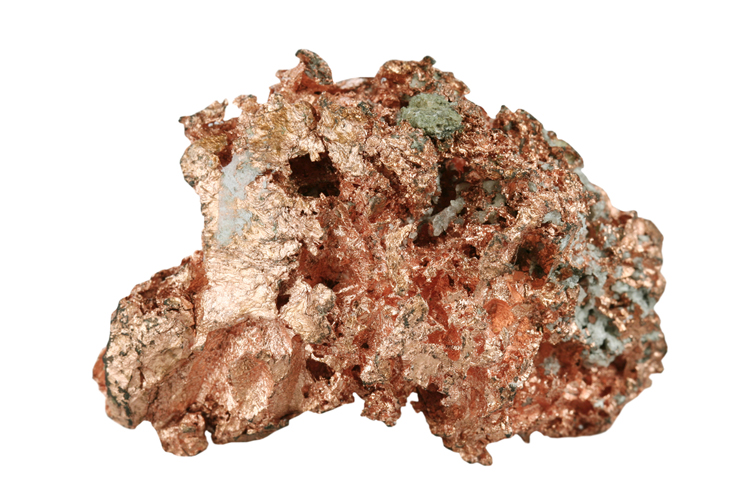

Copper is simply an incredible multimeter metal, which is closely related to our lives. Many of the early tools and weapons of human beings are made of copper. Its Latin name "Cuprum" originated from a place called Cyprus, which is a very rich island. People use the abbreviation CU of the island to name the metal material, so copper has the current code.

Copper plays a very important role in modern society: it is widely applied to the architectural structure, as a carrier that transmits power, in addition, it has been used in many different cultural backgrounds as raw materials for making body ornaments for thousands of years. . From the initial simple decoding, the key role that is later played in complex modern communication applications, this delay, orange metal is accompanied by our development progress. Copper is an excellent conductive body, and its conductive properties are second only to Silver. From the point of use of metallic materials, the copper is second only to gold for human use of the longest metal. This is a large extent because copper mines are easily mining, and the copper industry is easier to separate from copper mine.

Material characteristics: good corrosion resistance, excellent thermal conductivity, conductivity, hard, flexible, delays, post-polishing, unique effects.

Typical use: wire, engine coil, printed circuit, roof material, pipeline material, heating material, jewelry, cookware. It is also one of the major alloy components for bronze.

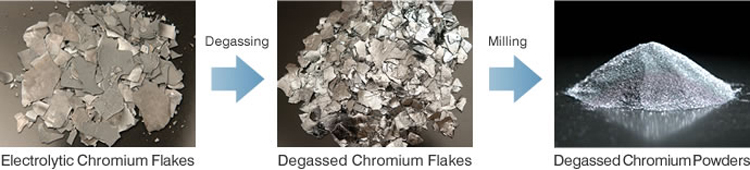

The most common form of chromium is used as alloying elements for stainless steel to enhance the hardness of stainless steel. Chrome-plated processes are usually divided into three types: decorative plating, hard chrome plating, and black chrome plating. The chromium plating is equivalent to the application in the engineering field, and the decorative chrome plating is usually plated outside the nickel layer as the top surface, and the coating has exquisite and delicate polishing effects. As a decorative post-treatment process, the thickness of the chromium plating is only 0.006 mm. When intending to use a chromium plating process, it is necessary to fully take into account the risk of this process. In the past decade, the trend of six-price decorative chromium water was increasingly obvious, as the former had very strong carcinogenicity, while the latter was considered to be relatively small.

Material characteristics: very high finish, excellent corrosion resistance, hard and durable, easy to clean, low friction coefficient.

Typical use: Decorative chrome plating is a plating material of many automotive components, including door handle and buffer, etc. In addition, chromium is also used in bicycle components, bathroom faucets, and furniture, kitchen utensils, tableware, etc. Hard chrome is more useful for industrial sectors, including random memory, jet engine components, plastic molds, and shock absorbers in the work control block. Black chrome is mainly used for instrumental decoration and solar utilization.

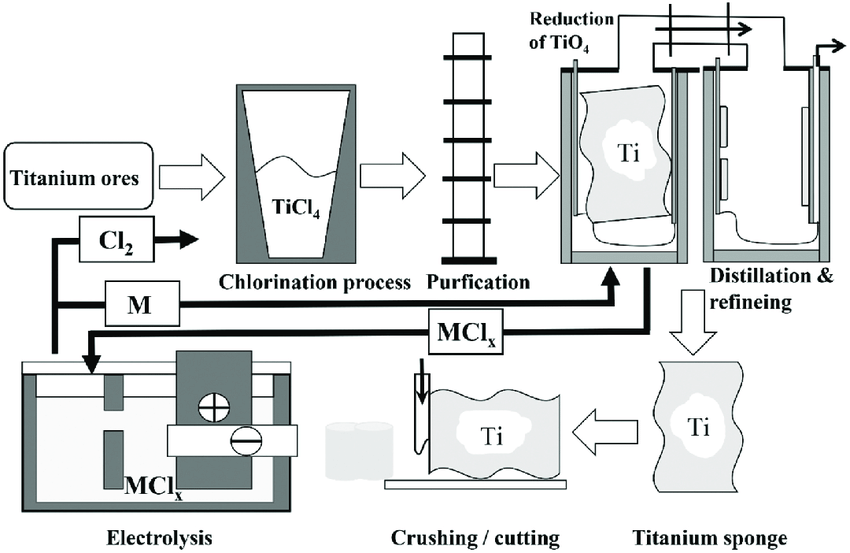

Titanium is a very special metal, the texture is very light, but it is very tough and corrosion, keeping the tones of itself at room temperature. The melting point of titanium is much different from platinum, so it is often used in aerospace. Military precision components. Different colors are produced after adding current and chemical treatment. The titanium has excellent acid alkali corrosion. If the titanium is added to stainless steel, only one percent, it greatly improves rust.

Titanium has excellent density, high temperature resistance, corrosion resistance, etc., titanium alloy density is half of steel and intensity and steel is similar; titanium is both high temperature and low temperature. High strength can be maintained in such a wide temperature range in -253 ° C ~ 500 ° C. These advantages are essential for space metal. The titanium alloy is a housing and artificial satellite, a spacecraft of the spacecraft, and is known as "space metal". Since titanium has these advantages, it has become a prominent metal with highlighter than these advantages.

Titanium is a pure metal, which is because of "pure" of titanium metal, so the material does not produce a chemical reaction when it is in contact. That is, because the corrosion resistance of titanium is high, it does not affect its nature after the long-term contact of the person, so it will not cause human allergies, it is the only impact on human plant nerves and taste. Metal, is known as "biological metal".

The biggest shortcoming of titanium is difficult to refine. This is mainly because titanium can be compounded with oxygen, carbon, nitrogen, and many other elements at high temperatures. Therefore, people have used titanium as "rare metals". In fact, the content of titanium is about 6 ‰, which is more than 10 times more than copper, tin, manganese and zinc.

Material characteristics: Very high strength, high weight ratio of corrosion resistance, difficult to carry out cold processing, good weldability, about 40% more than steel, 60% lower than aluminum, low conductivity, low thermal translation rate, high melting point.

Typical use: golf club, tennis racket, laptop, camera, suitcase, surgical implant, aircraft skeleton, chemical equipment, and maritime equipment. In addition, titanium is also used as white pigments required for paper, painting, and plastic.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...