What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

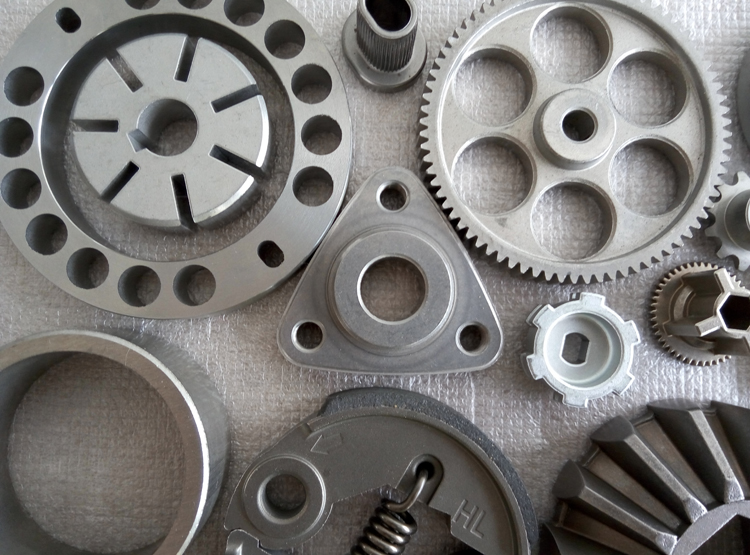

What is the difference between 201 st...The pores generated in the sintering process of powder metallurgy materials are their inherent characteristics, which also have a great influence on the heat treatment, especially the relationship between the change of porosity and the heat treatment. In order to improve the compactness and grain size, the added alloying elements are also Has a certain effect on heat treatment.

During the heat treatment of powder metallurgy materials, rapid cooling is used to inhibit the diffusion of austenite into other structures, thereby obtaining martensite, and the existence of pores has a great influence on the heat dissipation of the material. By the thermal conductivity formula:

Thermal conductivity = Theoretical thermal conductivity of metal × (1-2 × porosity)/100

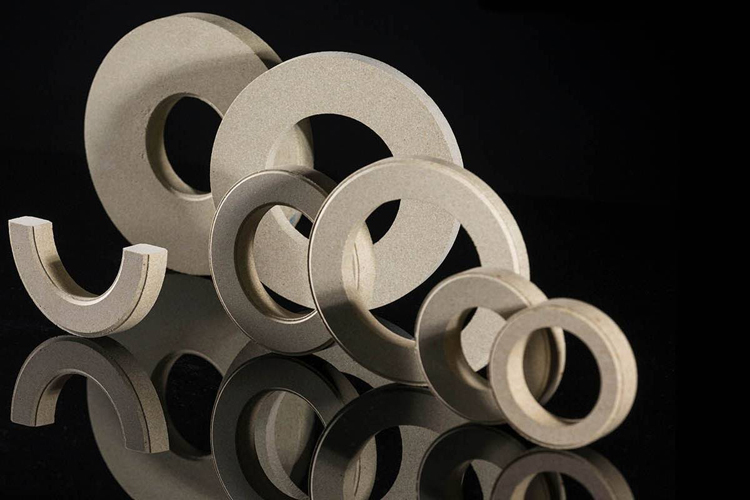

It can be seen that the hardenability decreases with increasing porosity. On the other hand, porosity also affects the density of the material, and the effect on the surface hardness and hardening depth of the material after heat treatment is related to the effect of density, which reduces the surface hardness of the material. Moreover, because of the existence of pores, brine cannot be used as a medium during quenching, so as to avoid corrosion caused by residual salt, so the general heat treatment is carried out in a vacuum or gas medium.

The heat treatment effect of powder metallurgy materials is related to the density, permeability (hardenability), thermal conductivity and electrical resistance of the material. Porosity is the biggest cause of these factors. When the porosity exceeds 8%, the gas will rapidly penetrate through the voids. In the case of carburizing hardening, increasing the carburizing depth reduces the effect of surface hardening. Moreover, if the infiltration rate of carburizing gas is too fast, soft spots will be generated during quenching, which will reduce the surface hardness and make the material brittle and deformed.

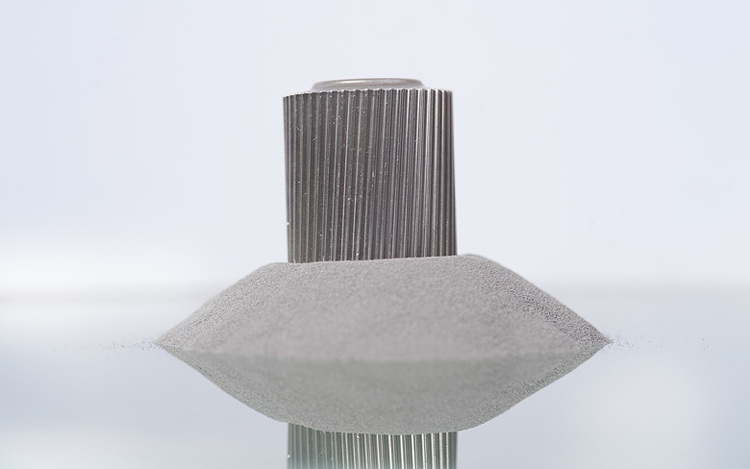

Common alloying elements are copper and nickel, and their content and type will affect the heat treatment effect. The depth of heat treatment hardening increases with the increase of copper content and carbon content and gradually decreases when it reaches a certain content; the stiffness of nickel alloy is greater than that of copper alloy, but the inhomogeneity of nickel content will lead to inhomogeneous austenite structure.

Although high temperature sintering can achieve the best alloying effect and promote densification, the difference in sintering temperature, especially when the temperature is lower, will lead to decreased heat treatment sensitivity (reduced alloy in solid solution) and mechanical properties. Therefore, using high-temperature sintering, supplemented by a sufficient reducing atmosphere, can obtain a better heat treatment effect.

The heat treatment process of powder metallurgy materials is a complex process, which is related to porosity, alloy type, alloy element content, and sintering temperature. Compared with dense materials, the internal uniformity is poor. In order to obtain higher hardenability In order to increase the full austenitization temperature and prolong the time, heterogeneous austenite carburization can obtain a high carbon concentration that is not limited by the austenite saturated carbon concentration. In addition, adding alloying elements can also improve the hardenability. Steam treatment can significantly improve its corrosion resistance and surface hardness.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...