What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

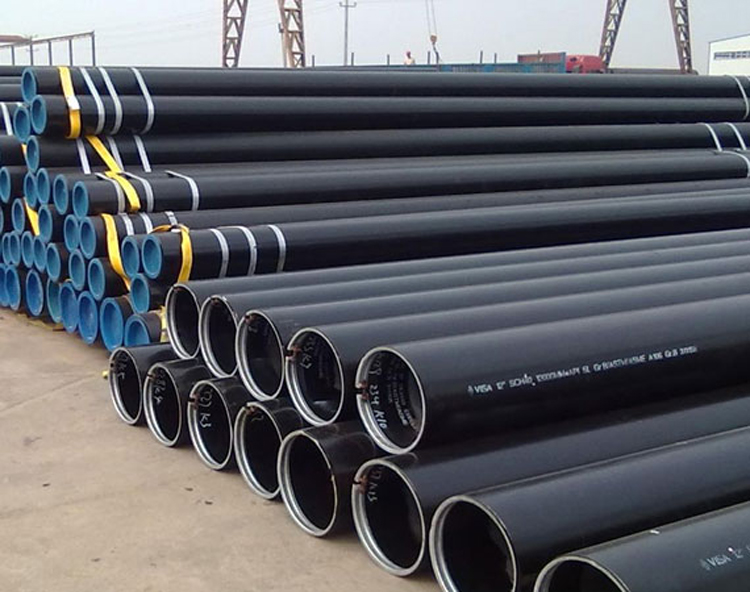

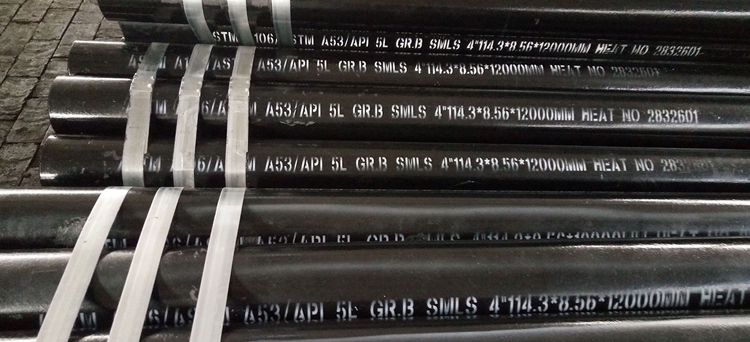

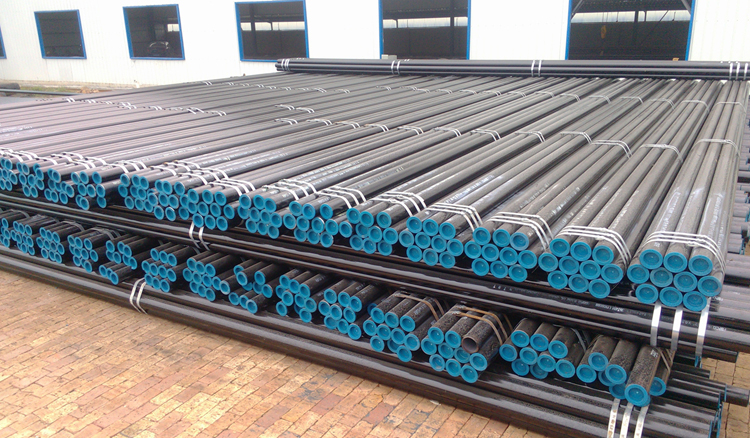

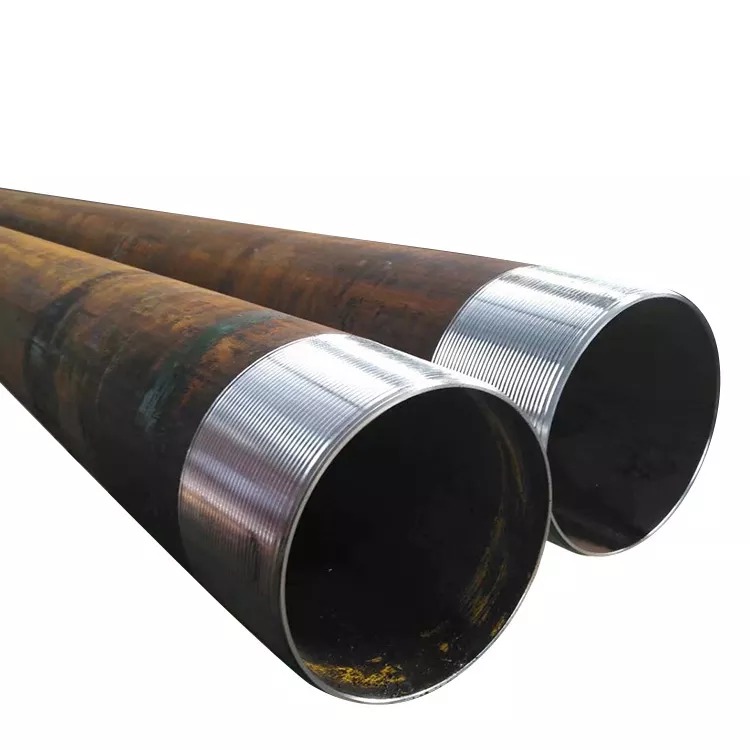

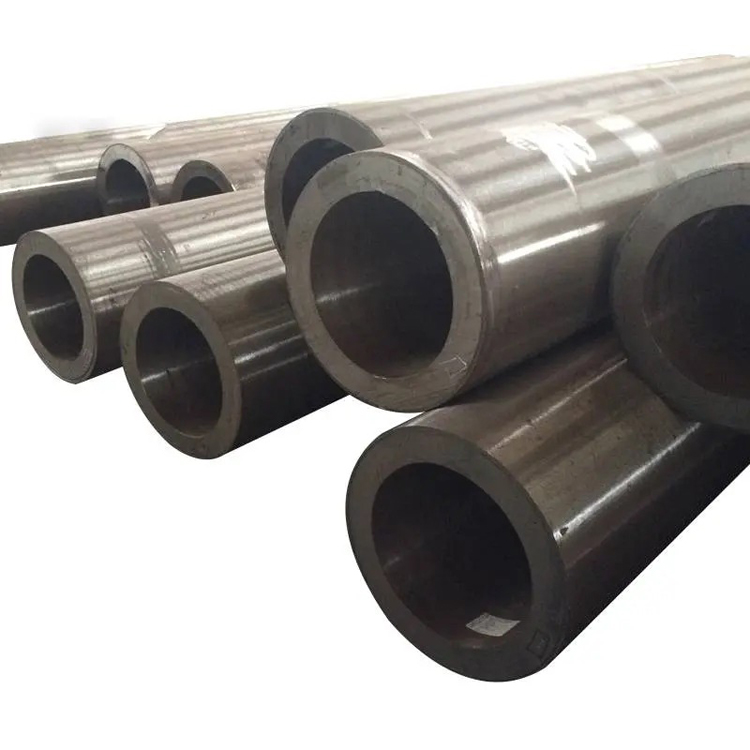

What is the difference between 201 st...Seamless steel pipes are steel pipes without welds manufactured by hot working methods such as piercing hot rolling. If necessary, the hot worked tube can be further cold worked to the desired shape, size and properties.

At present, seamless steel pipe (DN15-600) is the most widely used pipe in petrochemical production equipment.

GB/T9711 "Technical conditions for delivery of steel pipes for oil and gas industry"

GB6479 "High Pressure Seamless Steel Tube for Fertilizer Equipment"

GB9948 "Seamless Steel Pipes for Petroleum Cracking"

GB3087 "Seamless steel pipes for low and medium pressure boilers"

GB/T5310 "Seamless Steel Tubes for High Pressure Boilers"

GB/T8163:

Material grades: 10#, 20#, Q345, etc.

Scope of application: Oil products, oil and gas and public media with design temperature less than 350℃ and pressure less than 10MPa.

GB6479:

Material grades: 10#, 20G, 16Mn, etc.

Scope of application: design temperature -40 ~ 400 ℃, design pressure 10.0 ~ 32.0MPa oil, oil and gas.

GB9948:

Material grades: 10#, 20#, etc.

Scope of application: occasions where GB/T8163 steel pipes are not suitable.

GB3087:

Material grades: 10#, 20#, etc.

Scope of application: superheated steam and boiling water of low and medium pressure boilers.

GB5310:

Material grade: 20G, etc.

Scope of application: superheated steam medium of high pressure boiler.

Generally, steel pipes for fluid transportation must be subjected to chemical composition analysis, tensile test, flattening test and hydraulic test.

The three standard steel pipes of GB5310, GB6479 and GB9948 require flaring test and impact test in addition to the tests that must be carried out on steel pipes for fluid transportation; the manufacturing inspection requirements of these three kinds of steel pipes are relatively strict.

The GB6479 standard also makes special requirements for the low temperature impact toughness of the material.

In addition to the general test requirements of steel pipes for fluid transportation, the steel pipes of GB3087 standard also require cold bending tests.

For steel pipes of GB/T8163 standard, in addition to the general test requirements of steel pipes for fluid transportation, flaring test and cold bending test are required according to the agreement. The manufacturing requirements for these two types of tubes are less stringent than for the first three.

The steel pipes of GB/T8163 and GB3087 standards are mostly smelted by open hearth or converter, and their impurity components and internal defects are relatively large.

GB9948 is mostly smelted by electric furnace. Most of them have added out-of-furnace refining process, with relatively few components and internal defects.

The GB6479 and GB5310 standards themselves specify the requirements for out-of-furnace refining with the least impurity composition and internal defects and the highest material quality.

The order of manufacturing quality grades of the above steel pipe standards from low to high:

GB/T8163 < GB3087 < GB9948 < GB5310 < GB6479

Under normal circumstances, the steel pipe of GB/T8163 standard is suitable for oil, oil and gas and public media with design temperature less than 350℃ and pressure less than 10.0MPa;

For oil and oil and gas media, when the design temperature exceeds 350°C or the pressure exceeds 10.0MPa, the steel pipe of GB9948 or GB6479 standard should be used;

GB9948 or GB6479 standards should also be used for pipelines operating in the presence of hydrogen, or pipelines working in an environment prone to stress corrosion.

All carbon steel pipes used at low temperature (less than -20 ℃) should adopt GB6479 standard, only it specifies the requirements for low temperature impact toughness of materials.

GB3087 and GB5310 standards are standards specially set for boiler steel pipes.

"Boiler Safety Supervision Regulations" emphasizes that all pipes connected to boilers are within the scope of supervision, and the application of their materials and standards should comply with the "Boiler Safety Supervision Regulations". Therefore, boilers, power plants, heating and petrochemical production equipment use The public steam pipelines (supplied by the system) should adopt GB3087 or GB5310 standards.

It is worth noting that the price of steel pipes with good quality steel pipe standards is also relatively high. For example, the price of GB9948 is nearly 1/5 higher than that of GB8163 materials. Therefore, when selecting steel pipe material standards, it should be comprehensively considered according to the conditions of use. It must be reliable and reliable. To be economical. It should also be noted that steel pipes according to GB/T20801 and TSGD0001, GB3087 and GB8163 standards shall not be used for GC1 pipelines (unless ultrasonically, the quality is not lower than L2.5 level, and can be used for GC1 with design pressure not greater than 4.0Mpa (1) pipeline).

In petrochemical production plants, the commonly used standards for chrome-molybdenum steel and chrome-molybdenum vanadium steel seamless steel pipes are:

GB9948 "Seamless Steel Pipes for Petroleum Cracking"

GB6479 "High Pressure Seamless Steel Tube for Fertilizer Equipment"

GB/T5310 "Seamless Steel Tubes for High Pressure Boilers"

The chrome molybdenum steel material grades included in GB9948: 12CrMo, 15CrMo, 1Cr2Mo, 1Cr5Mo, etc.

The chrome molybdenum steel material grades included in GB6479: 12CrMo, 15CrMo, 1Cr5Mo, etc.

The material grades of chrome molybdenum steel and chrome molybdenum vanadium steel included in GB/T5310: 15MoG, 20MoG, 12CrMoG, 15CrMoG, 12Cr2MoG, 12Cr1MoVG, etc.

Commonly used stainless steel seamless steel pipe standards are:

There are five standards in total: GB/T14976, GB13296, GB9948, GB6479, and GB5310. Among them, only two or three stainless steel material grades are listed in the latter three standards, and they are not commonly used material grades.

Therefore, when the stainless steel seamless steel pipe standard is selected in the project, the GB/T14976 and GB13296 standards are basically used.

GB/T14976 "Stainless Steel Seamless Steel Tubes for Fluid Transport":

Material grades: 304, 304L, etc., a total of 19 kinds are suitable for the transportation of general fluids.

GB13296 "Stainless Steel Seamless Steel Tubes for Boilers and Heat Exchangers":

Material grades: 304, 304L, etc. a total of 25 kinds.

Among them, ultra-low carbon stainless steel (304L, 316L) has excellent corrosion resistance. Under certain conditions, it can replace stable stainless steel (321, 347) for medium corrosion resistance; ultra-low carbon stainless steel has low high-temperature mechanical properties, generally It is only used when the temperature is lower than 525℃; the stable austenitic stainless steel has both good corrosion resistance and high high temperature mechanical properties, but the Ti in 321 is easily oxidized and lost during the welding process , thereby reducing its corrosion resistance, and its price is high. Such materials are generally used in more important occasions. 304 and 316 have general corrosion resistance and are cheap, so they are widely used.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...