What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

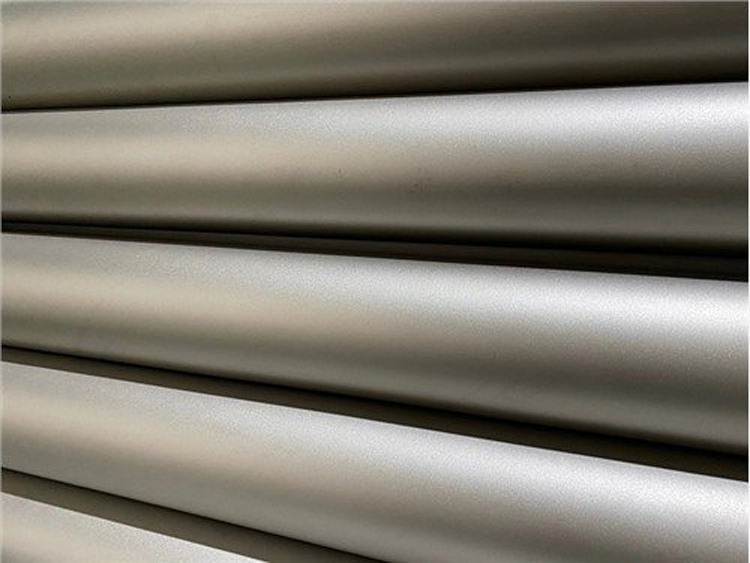

What is the difference between 201 st...Hastelloy X is a Fe-Ni-Cr-based solid-solution-strengthened deformed superalloy with moderate durability and creep strength at 900°C. It has good oxidation resistance and corrosion resistance, good cold and hot working formability and welding performance, suitable for making parts such as aero-engine combustion chambers that are used for a long time below 900 °C, and high temperature that can be used for a short time at a working temperature of 1080 °C. Components, mainly plates, strips, tubes, bars, forgings and castings.

chemical composition:

Chromium Cr: 20.5-23.5

Carbon C: ≤0.05-0.15

Iron Fe: 17-20

Manganese Mn: ≤1.00

Nickel Ni: Balance

Silicon Si: ≤1.0

Molybdenum Mo: 8.0-10.0

Cobalt Co: ≤0.5-2.5

Aluminum Al: ≤0.1

Tungsten W: ≤0.2-1.0

Vanadium V: ≤0.35

Boron B: ≤0.005

Silicon Si: ≤1.0

Phosphorus P: ≤0.015

Sulfur S: ≤0.01

Hastelloy X features: excellent oxidation resistance up to 1200°C, good high temperature strength, good formability and weldability, good stress corrosion cracking resistance.

Density 8.3 g/cm3

Melting point 1260-1355 ℃

Tensile strength Rm N/mm2:730

Yield strength RP0.2N/mm2:283

Elongation A5 %:40

Hastelloy X welding: It can be welded by various welding processes, such as tungsten electrode inert gas shielded welding, plasma arc welding, manual sub-arc welding, metal shielded metal shielded welding, and molten shielded shielded gas welding. Pulse arc welding is preferred.

Before welding, the material needs to be in solution treatment state to remove oxide scale, oil stains and various marking marks, and the width of about 25mm on both sides of the welding seam needs to be polished to a bright metal surface. With low heat input, the interlayer temperature does not exceed 100°C. No need for pre-weld and post-weld heat treatment.

Application areas: Industrial and aviation steam turbines (combustors, rectifiers, structural covers).

Industrial furnace components, support rolls, grids, ribbons and radiant tubes, helical tubes in petrochemical furnaces, high temperature gas cooling nuclear reactors.

Hastelloy X alloy is an austenitic nickel-based alloy containing 47.5% nickel, 22% chromium and 18.5% iron, with small amounts of cobalt, molybdenum and tungsten, and has excellent oxidation resistance at high temperatures.

Hastelloy X alloys are solution strengthened for excellent strength at elevated temperatures. It has excellent high temperature and stress rupture properties at 790°C. It is suitable for use in applications with a temperature limit of approximately 1200°C. Hastelloy X has high levels of chromium, nickel and molybdenum for excellent corrosion resistance, similar to high nickel alloys in corrosion applications.

Hastelloy X is known for its high resistance to heat and oxidation, as well as excellent resistance to chloride stress corrosion cracking, as well as excellent resistance to reduction and carburization.Extremely resistant to stress corrosion cracking in petrochemical applications.

Hastelloy X has excellent forming and welding properties. It is malleable and easy to cold work due to its high ductility. The alloy has a work hardening rate similar to that of austenitic stainless steels and exhibits good machinability in annealed form. It can be welded by fusion welding and resistance welding procedures. Hastelloy X can be welded by manual and automatic methods such as shielded metal arc welding, gas tungsten arc welding and gas metal arc welding processes.

Hastelloy X Executive Standards:

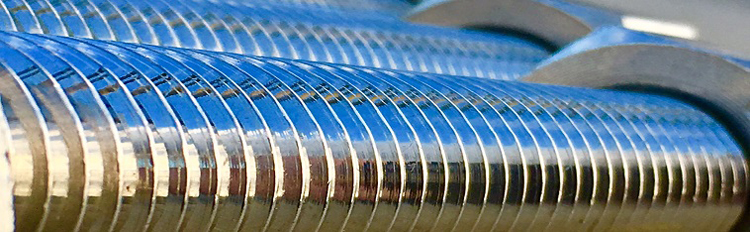

AMS 5536 Plates, Strips and Plates

AMS 5754 Rods, Forgings and Rings

AMS 5390 Castings (Casting)

AMS 5798 Welding Wire (Cold Drawn)

AMS 5799 Coated Welding Electrodes

GE B50T83A sheet

GE B50A436A board, board

GE B50TF25A sheet

PWA 1038 Low Temperature Sheet Strip

PDS 15102QE

ASTM B 435 Plates, Sheets and Strips

ASME SB-435 Plates, Sheets and Strips

ASTM B572

ASME SB-572

ASTM B 619 Welded Pipe

ASME SB-619 Welded Pipe

ASTM B 622 SMLS Pipe

ASME SB-622 SMLS Pipe

ASTM B 626 Pipe

ASME SB-626

ASME SFA-5.14 ERNiCRrMo-2 welding wire

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...