What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...Primary aluminum is forged with the original ecological aluminum material, which is pure aluminum extracted from the aluminum ore bauxite obtained by mining aluminum ore through the electrolytic cell.Compared with recycled aluminum, it has stronger strength, hardness, toughness, oxidation resistance and longer service life.

Recycled aluminum is an aluminum alloy or aluminum metal obtained by remelting and refining scrap aluminum and scrap aluminum alloy materials or aluminum-containing scraps, and is an important source of metal aluminum.Aluminum is a recyclable resource. At present, recycled aluminum accounts for more than 1/3 of the world's annual production of primary aluminum. Recycled aluminum has the same properties as primary aluminum, and can be remelted, refined and purified from recycled aluminum ingots, and chemically adjusted to make various cast aluminum alloys and deformed aluminum alloys, and then processed into aluminum castings or plastically processed aluminum.

Primary aluminum and recycled aluminum products are all kinds of standard or non-standard aluminum alloy ingots, the main difference is the different materials. The raw material of primary aluminum is bauxite, and the raw material of recycled aluminum includes scraps, scraps and cuttings generated during the production and processing of various aluminum materials, as well as aluminum waste generated after aluminum-containing products are scrapped, such as old aluminum doors and windows.

1) Different sources: Recycled aluminum alloys are smelted from scrap aluminum and recycled aluminum, which is an important source of metal aluminum. The process he needs is simpler and the cost is lower. Primary aluminum alloys are pure aluminum extracted from aluminum ore and refined through electrolytic cells.

2)Different colors: The cut cross-section of recycled aluminum alloys is dark in color and lacks luster. The cut cross-section color of the virgin aluminum alloy is somewhat similar to the luster of a diamond, with a slight bluish color. The surface of the aluminum material made of primary aluminum is very bright, just like a diamond; if it is recycled aluminum, its section is matte, and the color is not so bright, giving people a wooden feeling.

3) The composition is different: distinguish the raw material composition between the two. If the composition contains other trace elements, such as calcium, lead, zinc, chromium, etc., it is recycled aluminum alloy. If scrap aluminum is added, it is recycled aluminum. The content and mass fraction of primary aluminum vary greatly, which is basically not an order of magnitude.

Due to the difference in cost, the market price of products produced with primary aluminum will be higher than the price of secondary aluminum.

4)Different prices: profiles produced from primary aluminum will be more expensive; aluminum profiles extruded from recycled aluminum are cheaper.

5)The sound is different: when the aluminum profile made of primary aluminum hits it, it makes a very clear sound; when the aluminum profile made of recycled aluminum hits it, the sound is dull.

6)Different touch: the profiles extruded from primary aluminum have a smooth surface and feel comfortable; the profiles extruded from recycled aluminum have spots on the surface and rough handle.

7)Different oxidative hardness: primary aluminum has better strength, hardness, and oxidation resistance, and is not easy to rust and deform; recycled aluminum has less oxidation resistance and hardness than primary aluminum, and is easy to rust and deform.

Aluminum comes from bauxite, 90% of which is used to extract aluminum metal, and 10% of non-metal is mainly used to produce refractory materials, abrasive materials, chemicals and raw materials for high-alumina cement.

1)Aluminum production process:

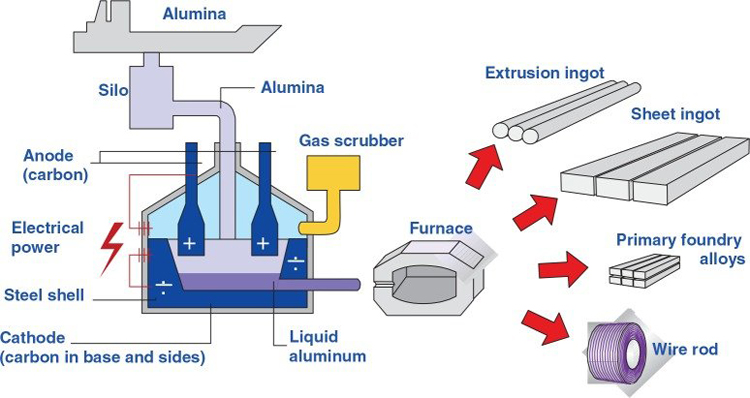

The bauxite (containing 50-60% of A12O3) is subjected to special mechanical processing to improve its purity, and then chemically precipitates alumina, and then dissolves the alumina in cryolite and electrolyte to separate the aluminum liquid. The molten aluminum is cast into ingots, that is, electrolytic aluminum or primary aluminum. The "standard aluminum" registered on the London Metal Exchange (LME) is electrolytic aluminum with a purity of 99.7%.

2)The production process of electrolytic aluminum is as follows:

4~5 tons of bauxite (Bayer method) → 2 tons of alumina (Hall-Heroult electrolysis method) → 1 ton of electrolytic aluminum.

Aluminum smelting is an electrochemical process. At 940-960 ℃, 60-350KA direct current is passed through the carbon anode, so that the alumina in the electrolytic cell is decomposed into aluminum and carbon dioxide in the molten fluoride salt, and the electrolytic aluminum chemical reaction The formula is: 2 A12O3 + 3C = 4Al + 3CO2.

It takes about 2~2.5 tons of bauxite to manufacture one ton of alumina, and consumes 8500~12000MJ of thermal energy; and manufacturing one ton of metal aluminum also requires two tons of alumina. In 1950, the production of 1 metric ton of primary aluminum required 20,000 kilowatt-hours (kWh) of electricity, but now it has dropped below 13,000 kilowatt-hours and produces 11 metric tons of CO2. The aluminum smelting industry still needs to consume a lot of electricity. Bauxite and areas with cheap electricity.

Metal aluminum is the second most important metal in the world after steel. Aluminum has a small specific gravity (2.7), good electrical and thermal conductivity, easy machining and many other excellent properties, so it is widely used in various industries. Currently, the world's largest aluminum use is in the construction, transportation and packaging sectors, accounting for more than 60% of total aluminum consumption.

Recycled aluminum refers to metal aluminum obtained through at least one casting or processing and recycling and processing. The existing form of recycled aluminum is generally aluminum alloy.

Scrap aluminum is divided into "new scrap aluminum" and "old scrap aluminum". Generally, scrap aluminum refers to old scrap aluminum and new scrap aluminum that is sold to recycling or recycled aluminum enterprises.

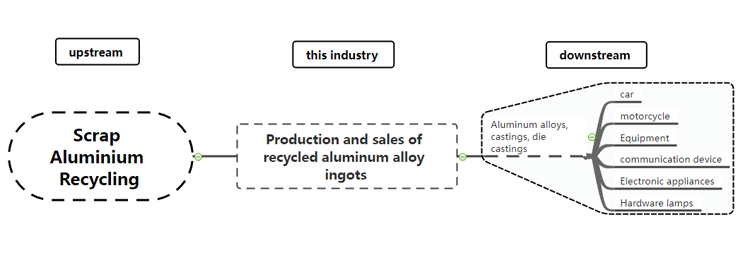

The recycled aluminum industry belongs to the upstream raw material industry. The upstream is mainly the industry that supplies scrap aluminum materials, and the downstream is the production enterprises of aluminum alloy die castings and castings.

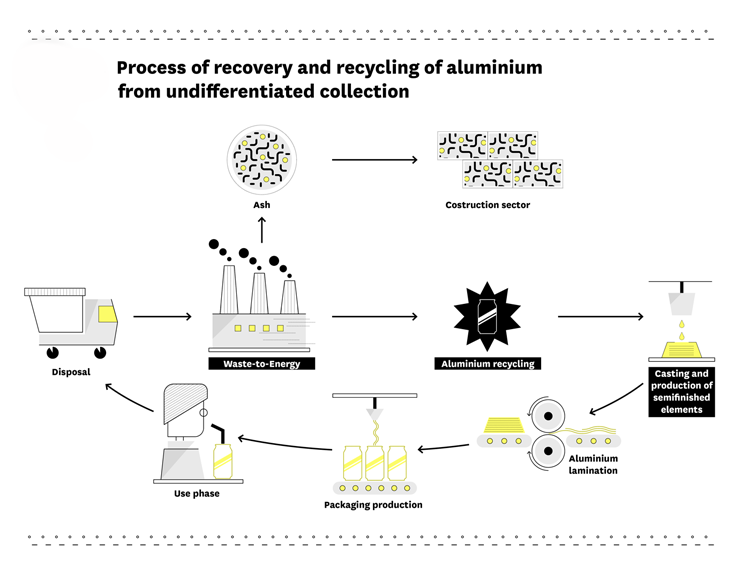

The production process of recycled aluminum alloy ingots mainly includes sorting, pretreatment and smelting, ingot casting and other processes. First, it is necessary to separate non-metallic substances such as plastics from metal substances in raw materials through sorting and pretreatment, and separate and classify other metals in metal substances.

After the aluminum material is melted and alloyed according to the proportion, the aluminum liquid needs to be refined to ensure the quality of the aluminum alloy liquid. The molten aluminum slag produced in the above process will be processed in the ash frying workshop again, and a small amount of aluminum alloy liquid remaining in the aluminum slag will be separated again. The rest of the refined aluminum liquid will be cast or die-cast, and packaged and put into storage after passing the inspection.

There are significant economic advantages to recycling aluminium scrap. Due to the strong corrosion resistance of aluminum metal, except for some chemical containers and devices made of aluminum, aluminum is almost not corroded during use, with very little loss, and can be recycled many times. Therefore, aluminum has a strong recyclability. and the use of recycled scrap aluminum to produce aluminum alloys has significant economic advantages over primary aluminum production.

Upstream scrap aluminum is divided into "new scrap aluminum" and "old scrap aluminum". "New scrap aluminum" refers to the process waste and scrapped parts generated in the production process of aluminum products. "Old scrap aluminum" refers to scrap aluminum and scrap aluminum parts recycled from society after aluminum products are consumed. Generally speaking, "scrap aluminum" includes old scrap aluminum as well as new scrap aluminum sold externally.

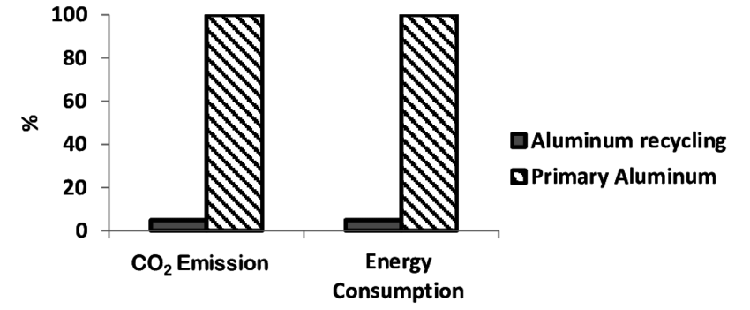

Compared with the production of the same amount of primary aluminum, the energy consumption in the production of recycled aluminum is only 3%-5% of the former. The production of 1 ton of recycled aluminum can save 3.4 tons of standard coal, 14 tons of water, and reduce solid waste discharge by 20%. Ton. With the increasing shortage of resources and the increase of environmental management costs, the advantages of secondary aluminum production have become increasingly prominent.

The material cost of scrap aluminum is the main production cost of recycled aluminum alloys. The social holdings of domestic scrap aluminum continue to grow, forming "urban minerals" with huge value and low recovery costs. At the same time, the continuous improvement of the waste resource recovery system helps reduce waste The material cost of aluminum expands the profit margin of the industry.

In recent years, recycled aluminum is mainly used to produce aluminum alloy castings and die castings in the industries of automobiles, motorcycles, mechanical equipment, communication electronics, electronic appliances and hardware lamps. At present, automobiles, motorcycles and electric vehicles account for the entire downstream consumption. than nearly 70%.

The early popularization of aluminum for automobiles is the parts such as wheels, cylinder heads, cylinder blocks, crankcases, intake pipes, pulleys, gearboxes, oil pumps, etc. These parts are generally made of cast aluminum alloys. In recent years, the lightweight of automobiles has developed rapidly, and the amount of aluminum used has been expanded to cover parts, all-aluminum body and other components.

The motorcycle industry is an industry that uses a lot of aluminum alloys, most of which are recycled aluminum castings, including crankcases, cylinder heads, cylinder blocks, shock absorbers, brakes, side covers, handles, side cover connectors, handlebars cover etc.

Recycled aluminum is widely used in the machinery and equipment industry. Typical applications are internal combustion engines, transmission parts, motors and boxes, shells, covers and other mechanical parts of various machines.

The application of recycled aluminum alloy in the field of communication and electronics is mainly various aluminum alloy structural parts and aluminum alloy appearance parts. Aluminum alloy demand is expected to fully benefit from the acceleration of 5G construction.

In the field of consumer electronics, it is mainly the all-aluminum chassis, aluminum middle frame and internal aluminum structural parts of mobile phones and notebook computers.

Household appliances are an important application industry of recycled aluminum. Recycled aluminum alloy materials are widely used in the manufacture of parts, casings, and frames of household appliances such as air conditioners, refrigerators, and washing machines. Its demand is expected to grow steadily with the improvement of real estate completion. .

In daily necessities, in addition to household appliances, recycled aluminum alloys are also widely used in the lighting industry due to their advantages of light material, high strength, and convenient processing.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...