What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...In actual production, the hypoeutectoid steel with ωc<0.6% and the hypereutectoid steel with ωc>1.2% are air-cooled after casting, hot rolling and forging, air-cooled in the weld or heat-affected zone, or when the temperature is too high and During rapid cooling, pro-eutectoid ferrite or pro-eutectoid cementite grows from the austenite grain boundary along a certain crystal plane of austenite into the grain, and precipitates in the form of needle flakes.

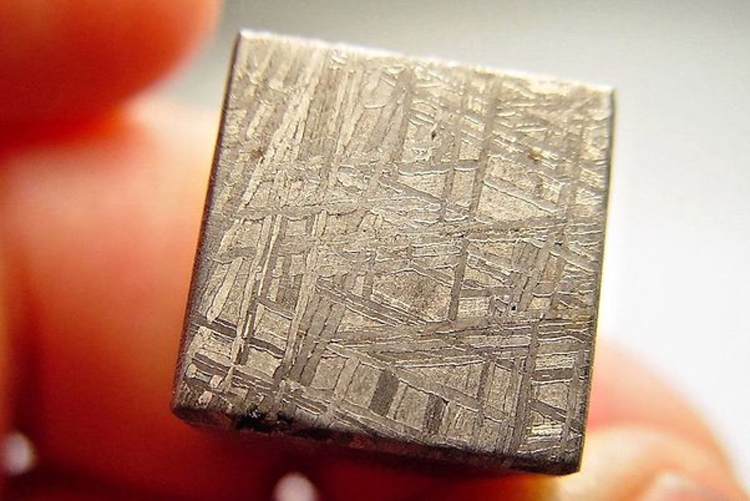

Near-parallel or other regularly arranged acicular ferrite or cementite grown from austenite grain boundaries and the pearlite structure in between can be observed under a metallographic microscope, which is called Widmandelsteiner structure .

The ferrite in the Widmandarin structure is formed according to the shear mechanism, which is similar to the formation mechanism of ferrite in bainite, and the sample will also appear embossed. Since ferrite is formed at a faster cooling rate, ferrite can only precipitate along a specific crystal plane of austenite, and has a crystallographic orientation relationship with the parent austenite.

This acicular ferrite can be directly precipitated from austenite, or it can first precipitate network ferrite along the austenite grain boundary, and then grow parallel to the intragranular from the network ferrite. When the ferrite in the Widmandelstein structure is formed, the carbon in the ferrite diffuses into the parent phase austenite on both sides, so that the austenite carbon content between the ferrite needles increases continuously, and finally transforms into pearlescent body. The ferrite formed by the bainite transformation mechanism is actually carbon-free bainite.

The formation of the Widmancer's structure is related to the carbon content, austenite grain size and cooling rate (transformation temperature) in the steel. The following figure shows the formation temperature and carbon content range of various ferrite and cementite.

It can be seen from the figure that the Widmandarin structure (W region) can be formed only in a relatively fast cooling rate and a certain range of carbon content. When the mass fraction of carbon in the hypoeutectoid steel exceeds 0.6%, due to the high carbon content, the probability of forming a carbon-depleted area is very small, so the Widmandarin structure is difficult to form. Studies have shown that for hypoeutectoid steel, when the austenite grains are small, only the carbon content is in the narrow range of ωc=0.15%~0.35%, and the cooling rate is fast.

The finer the austenite grains, the easier it is to form a network of ferrite, and it is not easy to form a Widmandelstein structure. The coarser the austenite grains, the easier it is to form the Widmanderin structure, and the range of the carbon content that forms the Widmandarin structure becomes wider. Therefore, the Widmandarin structure usually appears with the austenite coarse-grained structure.

(1) Widmanstatten structure is a superheated structure of steel. It significantly reduces the mechanical properties of the steel, especially the impact toughness and plasticity, and increases the brittle transition temperature of the steel, thus making the steel prone to brittle fracture.

(2) General research points out that only when the austenite grains are coarsened, the coarse ferrite or cementite Widmandarin structure appears and the matrix is severely cut, the strength and impact toughness of the steel are significantly reduced, and when When the austenite grains are relatively fine, even if there is a small amount of acicular ferrite Widmandarin microstructure, it does not significantly affect the mechanical properties of the steel. This is due to the finer substructure and higher dislocation density of the ferrite in the Widmandelsteiner structure. Therefore, the reduction of the mechanical properties of the steel by the Widmanstatten structure is always associated with the coarsening of the austenite grains.

(3) When the Widmanstler structure appears in the steel or cast steel to reduce its mechanical properties, it should first be considered whether it is caused by the coarsening of austenite grains due to excessive heating temperature.

(4) For steels that are prone to widmandering structures, it can be controlled by rolling, reducing the final forging temperature, controlling the cooling rate after forging (rolling), or changing the heat treatment process, such as refining grains by quenching and tempering, normalizing, and annealing. , isothermal quenching and other processes to prevent or eliminate Widmanners organization.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...