What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

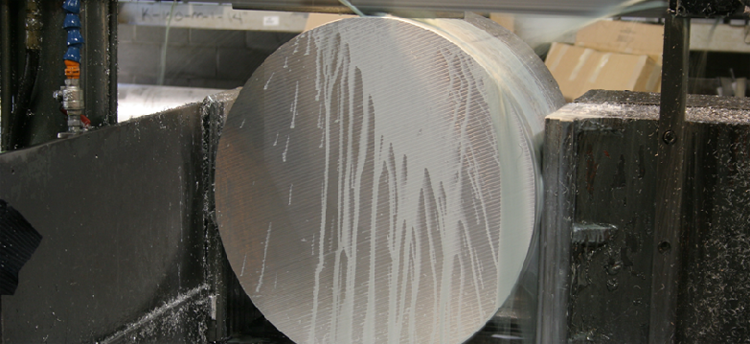

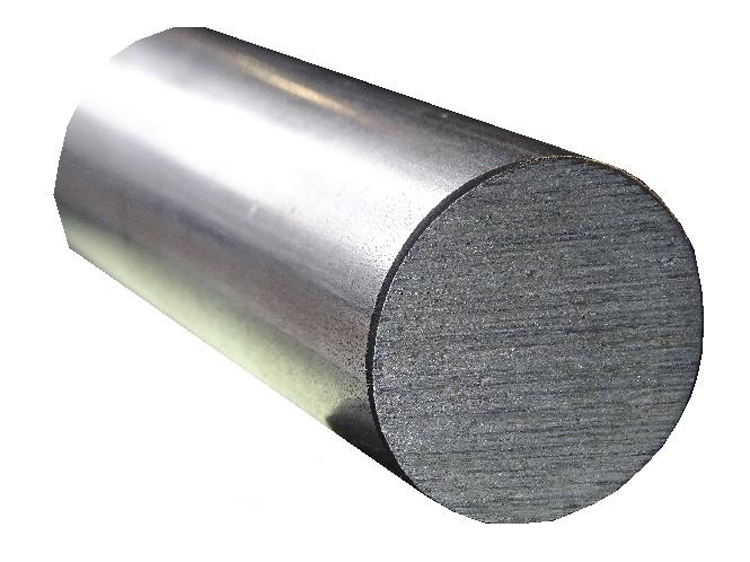

What is the difference between 201 st...The quality of large diameter cast round bars directly determines the performance and application of large forgings. Large cast rods are prone to defects such as uneven structure and properties, serious composition segregation, and cracking tendency, which seriously affect the utilization rate, yield, energy consumption, formability and service performance of the material. Ningbo Yinghe has the preparation technology of large-diameter cast round rods, improves the quality of large cast rods, in order to obtain large forgings that meet performance requirements, and can reduce the energy consumption of the preparation process, shorten the preparation process, reduce product costs, and can achieve product substitution, Expanded material applications.

1) Optimize the alloy composition ratio: the influence of the main composition and impurity content of the alloy on the performance of the alloy, determine the internal control standard of the alloy; improve the purity of the alloy, reduce the content of inherent impurities such as Ca, Fe, Na, Si, etc. in aluminum, and reduce the refractory melting phase, the number of excess phases; improve the uniformity of solute distribution in the solution, and improve the uniformity of the temperature field of the solution;

2) Homogenization of the casting process: to break through the difficulty of casting large-scale round bars, and adopt advanced melt purification and metamorphism treatment methods;

3) The comprehensive index of the ingot and its uniformity are improved: the tendency of ingot cracking is reduced, the grain size is reduced, the dendrite segregation is reduced, and the uniformity of the structure, composition and performance of the ingot is improved.

Aluminum alloy cast bars must be homogenized and annealed before forging to eliminate casting stress and uneven chemical composition. Ningbo Yinghe has perfect heat treatment parameters and processes to meet the requirements of homogenization annealing, strengthening solid solution and strengthening and toughening aging process, to ensure the advanced state of the alloy and the reasonable combination of various properties, and to improve the heat treatment quality and production efficiency of materials. Purpose.

1) In order to reduce the tendency to form porosity and reduce cold insulation, high temperature casting is generally used.

2) The casting speed is low.

3) The cooling water pressure of the soft alloy is larger than that of the small diameter of the same alloy. Because there is no tendency of cold cracking, it is not necessary to lay the bottom of the tempered hard alloy large-diameter ingot. The cooling water pressure is smaller than that of the small diameter of the same alloy. The gate part of the alloy with poor low temperature plasticity in the as-cast state needs to be tempered.

4) The base with dovetail groove can not be used.

5) Pay attention to prevent defects such as layering, cracks, feather crystals, looseness, optical crystals, and compound segregation during operation.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...