What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...

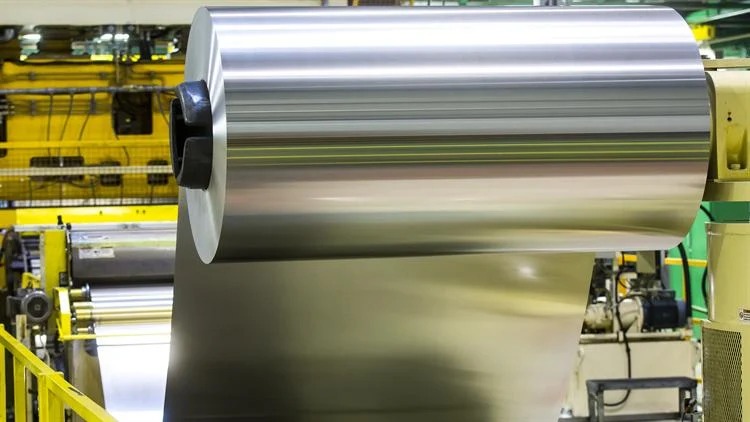

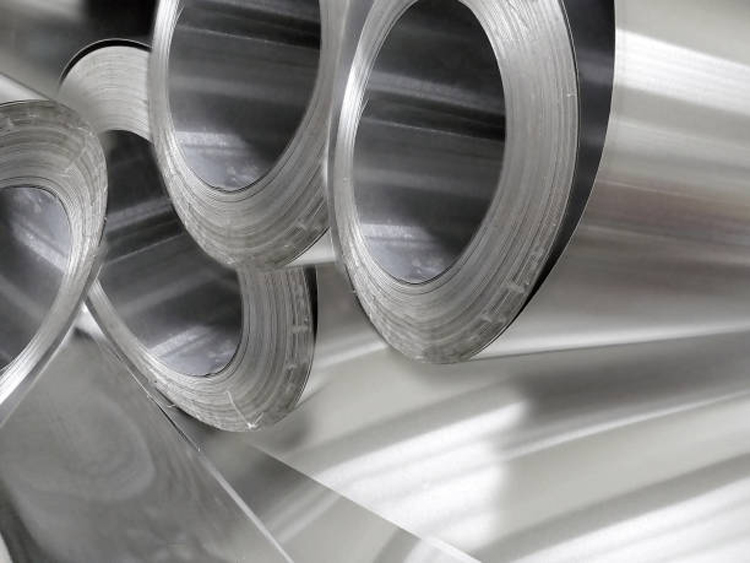

Aluminum coil is a metal product that is subjected to flying shear after being rolled by a casting and rolling mill and processed by bending. Aluminum coils are widely used in electronics, packaging, construction, machinery and other fields.

Several factors affecting the quality of aluminum coils:

6063 alloy is an alloy prepared with aluminum, magnesium and silicon as the main elements. Each element has a certain range of content. In order to reduce costs, some manufacturers reduce the amount of magnesium to the allowable content. In some cases, the magnesium content is less than the allowable content. There are also factories that add waste wires and waste pots and waste aluminum pots to the alloy, basically not talking about the 6063 alloy. As a result, the mechanical strength of the aluminum profile is very high, and it can be easily bent with both hands, commonly known as soft like noodles.

How the prepared 6063 alloy is melted and what kind of furnace is used is also crucial. Poor manufacturers use the original crucible boiler. There are coal-fired, oil-fired, gas-fired and electrically heated smelting furnaces. Some stoves have chimneys, while others have no chimneys. Generally, most of the square furnaces (rectangular furnaces) and circular furnaces are used. Some circular furnaces can be tilted to pour aluminum water. On the tonnage of one-ton, two-ton, five-ton, ten-ton, twenty-five-ton and fifty-ton aluminum melting furnaces. It is better to add a static furnace and a static furnace under the aluminum melting furnace.

In the preparation of 6063 alloy, the slag and gas can be removed in this furnace, and then the aluminum rod can be cast. The quality of alloys prepared in primitive coal-fired furnaces and modern circular furnaces is definitely not the same. In general, no matter what fuel is burned in a furnace, there should be a chimney, and most of the waste gas and slag produced during the combustion process of the fuel can be discharged from the chimney. If there is no chimney, the waste gas and slag are all melted in the aluminum water, so that the aluminum rod for extrusion is cast, and there are serious slag inclusion bubbles inside, which is one of the reasons for the poor quality of aluminum, and one of the reasons for the cheap aluminum price.

The level of casting equipment is also far away. The old casting equipment has an iron mold casting in the 40s, and some hydraulic pressure semi -continuous casting. The crystal tissue of the iron mold casting rod is very poor, and there are a lot of residue and bubbles in the casting rod. The quality of the cast stick is very poor. Most of the semi -continuous casting uses the wire rope to drive, good hydraulic transmission. The length of the semi -continuous casting rod is different, generally 3 meters and 4 meters until 8 meters. The semi -continuous casting is a pit type, while the casting is dropped, and it is cooled on all sides of the surrounding area.

Because the water is uniform around the water, the crystallization tissue of the cast stick is uniform and fine. However, the steel wire rope is transmitted downwards. It is not as smooth as hydraulic transmission. The surface of other cast rods on the surface of hydraulic casting sticks is smooth. The smooth surface of the cast stick is one of the prerequisites for squeezing good profiles. In other methods, the surface of the cast stick is rough. In order to ensure the quality of the type, sometimes the car is used to cast a rough appearance. The semi -continuous casting molds are currently commonly used. The characteristics of this casting mold can be cast several or dozens of dozens of them at a time. At the same time, the quality of the casting is good.

With the quality, the 6063 aluminum alloy cast rod can produce good aluminum profiles. If the original old casting equipment cannot be cast, it is impossible to produce good aluminum profiles at all. There are many aluminum factories in China that do not produce aluminum rod equipment. Instead, they purchase 6063 alloy rods from the aggressive aluminum plant or other factories. Such aluminum factories, aluminum materials are mastered in the hands of the production of cast sticks. It is difficult to achieve quality stability. The use of backward equipment and casting equipment, one is small investment and production expenses, which is one of the reasons why aluminum sales differences.

There are many kinds of profile extrusion machines, and the grades are very different. Some factories have their own simple extruders, some are transformed with extruders, and some are hydraulic or hydraulic. Good and bad extruders, the same cast bar, extruded profiles of different quality. We often see 6063T5 used for architectural aluminum doors and windows, which is an American brand for international use.

Aluminum coils often refer to the nominal pressure level of the fittings in the pipeline as the pressure level of the pipeline. The determination of the pressure level of the aluminum coil is the basis and the core of the design of the pressure pipeline. Aluminum plate and aluminum coil is the design prerequisite for pressure pipeline layout and pressure pipeline stress check. Aluminum ingot aluminum coil is also an important factor affecting pressure pipeline infrastructure investment and pipeline reliability.

The pressure grade of the pipeline: Usually, the parameters in the aluminum pipe that can reflect the pressure bearing characteristics of the aluminum coil, which are determined by the nominal pressure aluminum coil grade and the wall thickness grade of the standard pipe fittings, are called the pressure grade of the pipeline.

The components of pressure aluminum coils are generally standard parts. Therefore, the design of aluminum coils and pressure pipeline components is mainly the selection of their standard parts. The determination of the pressure level of aluminum coil pipes is also the determination of aluminum coils. The pressure grade of aluminum coil pipes includes two parts: the nominal pressure grade of standard pipe fittings expressed in terms of various aluminum coil nominal pressures; the wall thickness grade of standard pipe fittings expressed in terms of wall thickness grades.

First of all, the environment to be stored must be ventilated and dry. It is well known that aluminum skin is a non-ferrous metal. If it touches water, an oxidation reaction will occur, which will damage the protective film on the surface and affect the surface quality. Therefore, a dry environment is Basic conditions for depositing aluminum sheets.

The second is the airtightness of the packaging. Generally, the aluminum skin will be packaged with moisture-proof agent when it leaves the factory. Therefore, users are advised not to damage the packaging method. The packaging is suitable for long-term storage and use. If there are certain conditions, it can also be The aluminum skin after use is also packaged in this way.

Four precautions for aluminum coil storage:

(1) Wrap aluminum rolls with plastic film. If possible, it is best to place it where there is a desiccant. The desiccant can absorb the water in the air to avoid the problem of oxidation.

(2) If the aluminum tube is placed in a wooden box, it must be ensured that the humidity of the wooden box must be less than 18 %, and the temperature of the aluminum tube cannot be higher than 45 ° C.

(3) If we suddenly change from low -temperature areas to high -temperature areas during the placement process, we should not open the packaging immediately, because this is prone to oxidation, we should wait until the aluminum rolls are loaded before disassembling the packaging so that the oxidation will not occur.

(4) If there is rain and snow leakage in the warehouse, aluminum rolls should not be placed, because aluminum rolls can easily cause oxidation.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...