What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

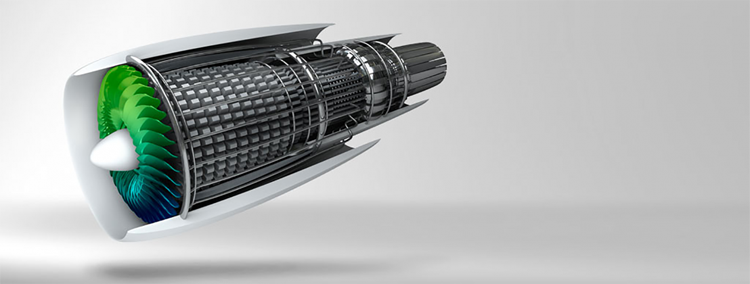

What is the difference between 201 st...Superalloy is a kind of metal material that can work for a long time above 600℃ and under certain stress conditions. It has excellent high temperature strength, good oxidation resistance and hot corrosion resistance, good fatigue performance, Fracture toughness and other comprehensive properties. The material characteristics of superalloys make them irreplaceable key materials in aero-engines. In the development of the world's advanced engines, the amount of superalloy materials has accounted for 40% to 60% of the total engine. Therefore, superalloy materials are also known as "the cornerstone of advanced engines".

Superalloy material is the preferred material for aero-engines, and it is in an irreplaceable position in the development of modern aviation industry. Its scale development directly determines the development level of aviation equipment. In addition, superalloys are also widely used in the hot end components of aerospace engines. With the development of industrialization, the demand for superalloy materials in the civil high-end equipment industry is on the rise. It is widely used in the civil industry, and the use of superalloys in the civil industry has increased to about 20%.

Superalloys can be divided according to the material forming method, the type of matrix elements, the type of alloy strengthening, etc.

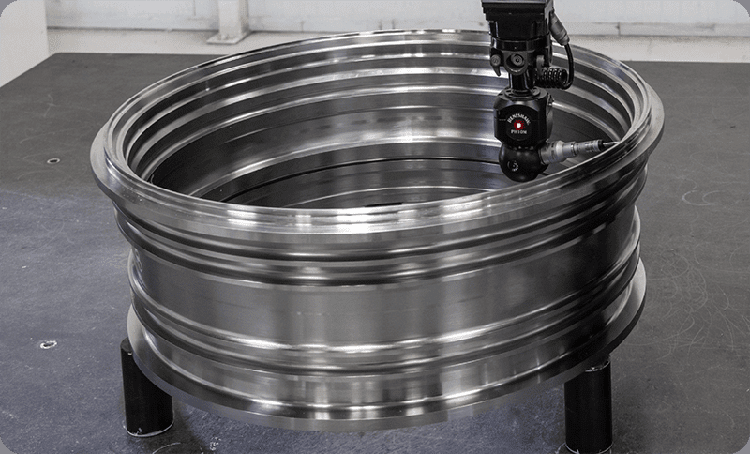

1) According to the material forming method, superalloys can be divided into deformed superalloys, cast superalloys (including ordinary precision casting alloys, directional solidification alloys, single crystal alloys, etc.), powder metallurgy superalloys (including ordinary powder metallurgy superalloys and oxides) dispersion strengthened superalloy (ODS);

2) According to the types of matrix elements, superalloys can be divided into iron-based, nickel-based, cobalt-based, etc.;

3) According to the type of alloy strengthening, superalloys can be divided into solid solution strengthening superalloys and aging precipitation strengthening alloys.

Various degradation rates of materials in high temperature environment are accelerated, and it is prone to tissue instability during use, deformation and crack growth under the action of temperature and stress, and oxidation and corrosion of material surfaces. The properties of high temperature resistance and corrosion resistance of superalloy mainly depend on its chemical composition and structure.

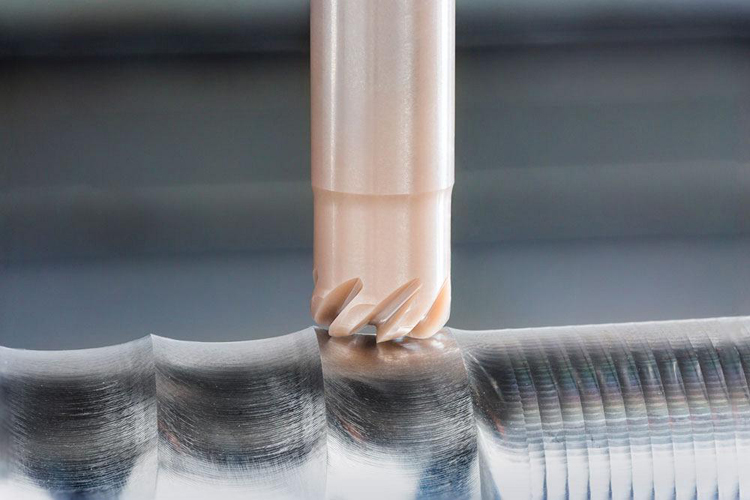

The composition of superalloy materials is very complex, containing active elements such as chromium and aluminum, which are chemically stable in oxidative or hot corrosion environments. Performance and mechanical properties have a very adverse effect. Due to the high degree of alloying, superalloy materials are prone to component segregation, which has a significant impact on the structure and properties of cast superalloys and deformed superalloys. These characteristics of superalloy determine its processing technology that is different from ordinary metal materials.

The development of superalloys is a process of continuous improvement and innovation of alloy theory and production technology. Through alloy strengthening + process strengthening, the material properties of alloys are continuously improved. Alloy strengthening includes solid solution strengthening of alloys, grain boundary strengthening of second-phase strengtheners, etc.; process strengthening includes improving smelting, solidification crystallization, hot working, heat treatment and surface treatment to improve alloy structure and so on.

The production process of superalloy mainly includes three processes: smelting, casting and heat treatment. The production process has a significant impact on the mechanical properties of superalloy materials. The introduction of a new process often makes the performance of superalloys a leap, and a number of new superalloys are developed to promote the development of a new generation of aero-engines and aircraft. Older types of alloys can also improve the process to achieve improved material properties.

For example, the application of single crystal turbine blades has significantly advanced the advancement of aero-engines. The turbine rotor blades of the aero-engine F119 used by the F-22 are selected from the third-generation single crystal superalloy PWA1484. The maximum working temperature of the material itself is about 1070 ° C. Due to the use of computational fluid dynamics programs to design and manufacture super cooling blades, Raising the working temperature of turbine rotor blades to 1621-1677°C (1400°C for the F100 engine) shows the importance of process innovation in material development.

The preparation technology and process of superalloy materials are still in continuous progress and innovation. For example, the smelting process adopts the triple process of vacuum induction + electroslag remelting + vacuum proud smelting, and the vacuum consumable smelting adopts the advanced smelting control method; the high temperature strength of the material is improved by the directional solidification columnar alloy and single crystal alloy technology; The powder metallurgy method is used to reduce the segregation of alloy elements and improve the material strength. In addition, oxide dispersion strengthened superalloys and intermetallic compound high-temperature materials are also constantly developing and innovating.

Studies have shown that superalloys for aero-engines account for more than half of the total demand for superalloys, and are also widely used in electric power, automobile, machinery and other industries.

Aero-engine, known as the "flower of industry", is one of the most technical and difficult components in the aviation industry. As an aero-engine of an aircraft power unit, it is particularly important that metal structural materials have the properties of light weight, high strength, high toughness, high temperature resistance, oxidation resistance and corrosion resistance, which are almost the highest performance requirements in structural materials.

The technological progress of aero-engines is closely related to the development of superalloys, which are the most critical structural materials to promote the development of aero-engines. Military aero-engines can generally use their thrust-to-weight ratio (thrust/weight) to comprehensively assess the level of the engine. The most direct and effective technical measure to increase the thrust-weight ratio is to increase the gas temperature before the turbine. Therefore, the performance and selection of superalloy materials are the key factors that determine the performance of aero-engines. With the continuous upgrading of aviation equipment, the thrust-to-weight ratio of aero-engines continues to increase, and engines rely more and more on high-performance superalloy materials.

The special working environment in aerospace engines requires that the materials used must be tested by high temperature, high pressure, high temperature gradient, high dynamic load and special rings, so high requirements are placed on the comprehensive performance and processing performance of the material. Superalloy materials have occupied a considerable proportion of aerospace engines, and the application ratio in the engine is close to half of the total weight. The development of superalloy material technology directly affects the development level of aerospace engines.

With the advancement of industrialization, the industry has developed to high-end and large-scale, and the demand for superalloys in the civilian industry is also increasing. Superalloy alloys are also the preferred materials for ships, trains, automobile turbocharger blades and various industrial gas turbine blades; the high-speed railway transportation, the high-quality requirements of the shipbuilding industry (especially export shipbuilding), and the high-efficiency requirements of ship power , the rapid development of industrial gas turbine applications, etc., are in urgent need of high-performance superalloy master alloys.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...