What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...Aluminum plate drawing is a process that repeatedly uses sandpaper to scrape the lines of aluminum plates. Its production process is mainly divided into three parts: dehydrated, sand mill, and water washing. Witrail aluminum is widely used in brushed aluminum -plastic panels, fireproof boards, aluminum frames, boutique cabinets, boutique doors and windows, puppet panels, signs, lighting, indoor and outdoor decoration, household appliances, luggage, gifts, furniture, electronic consumer goods and other fields. It is currently quite popular decorative board.

The drawing aluminum plate is mainly divided into straight lines, random lines, ripple brushes, rotor ribs, threading, etc. The following briefly introduces the molding method of the above -mentioned ritative aluminum plates:

(1)Straight-grained brushed aluminum plate: The straight-line pattern is processed on the surface of the aluminum plate by mechanical friction, which has the dual function of brushing off the surface of the aluminum plate and decorating the surface of the aluminum plate. Straight grain wire drawing has continuous wire grain and intermittent wire grain. Connecting wire drawing can be obtained by rubbing continuous horizontal lines on the metal surface with scouring pad or stainless steel brush. By changing the diameter of the steel wire of stainless steel, different thicknesses of lines can be obtained.

(2)Random-grained brushed aluminum plate: The random-grained brushed aluminum plate is a matt silk-patterned aluminum plate with irregular and no obvious lines obtained by rubbing the aluminum plate front and rear, left and right under the high-speed copper wire brush.

(3)Corrugated brushed aluminum sheet: The corrugated brushed aluminum sheet is generally made on a brushing machine and a wiping machine. The axial movement of the upper set of grinding rollers is used to grind the metal surface to obtain a wavy pattern.

(4)Twisted wire drawing aluminum plate: Rotary wire drawing aluminum plate is a kind of silk pattern obtained by rotating and polishing the metal surface with kerosene and polishing ointment by using wool column felt or grinding stone nylon wheel on the drilling machine. Ornamental finishing of shaped plates and small decorative shaped dials.

(5)Threaded brushed aluminum plate: The threaded brushed aluminum plate uses a small motor equipped with a circular felt on the shaft to fix it on the table, at an angle of 60 degrees to the table, and use the rotation of the felt and the linear movement of the carriage. The surface of the aluminum plate is rubbed with a thread pattern of the same width.

The brushed aluminum plate is extruded by continuous and special friction on the surface. According to the difference of the pattern type of the aluminum plate, the brushed aluminum plate also has different types of specifications. You can choose the corresponding brushed aluminum plate according to the requirements of your own products.

In order to improve the overall performance of the brushed aluminum sheet, the aluminum sheet manufacturers are also carrying out rigorous exploration, and gradually evolved from the traditional electroplating color to the coloring method of oxidation reaction. In this way, the metal color of the aluminum plate will be more realistic, and the various use characteristics of the brushed aluminum plate can also be effectively improved.

The production process of any brushed aluminum plate is cumbersome, and once there is a production error, the performance of the aluminum plate will be seriously affected. For ordinary aluminum plate users, in order to thoroughly understand the aluminum plate manufacturing process, it is indeed necessary to have a certain understanding of this aspect. But some level of understanding of these production methods is required.

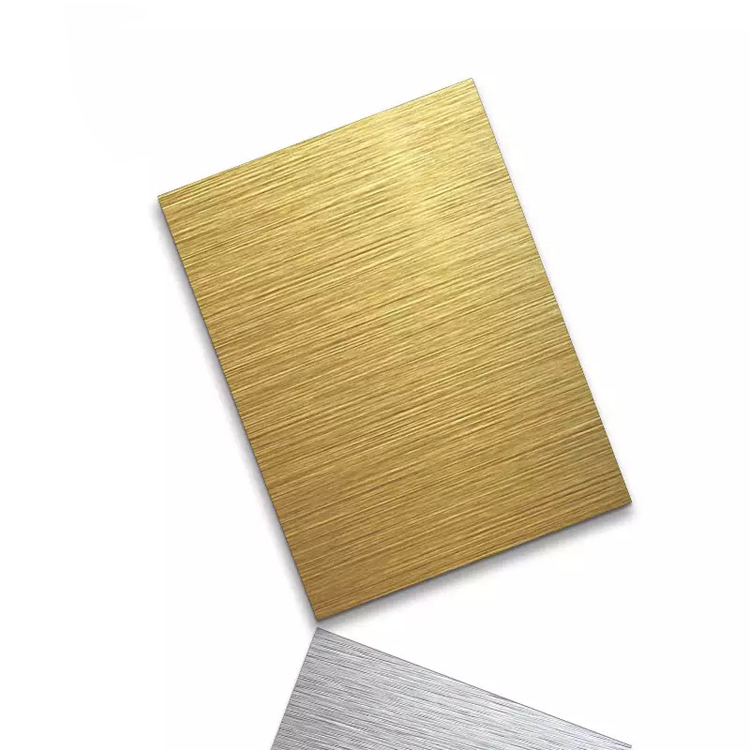

In metal pressure processing, the metal is forced through the die under the action of external force, the metal cross-sectional area is compressed, and the technical processing method of obtaining the required shape and size of the cross-sectional area is called the metal wire drawing process. The tool that makes it change shape. The size of the tool is called a wire drawing die. In order to break through the restrictions on the use of decorative materials and meet more creative needs, the wire drawing process originates from the human self-affirmation and exploration of the unknown in the new century, and the gold and silver wire drawing decorations that combine the power of knowledge and the spirit of science and technology have been developed and designed. face metal plate. This kind of product has gold wire drawing, silver wire drawing and sandblasting surface, which can fully reflect the heavy metal feeling that is difficult to express in other plates such as gold and silver. Gold and silver are rich and noble colors and are symbols of status and status.

The main metal materials used in gold and silver brushed veneer metal plates can be divided into three categories: aluminum, copper and stainless steel. With the texture, luster and characteristics of the original metal form, matte, mirror, three-dimensional, embossed and special Various surface treatments such as veneer and metal strands. According to the designer on different occasions, it shows a resplendent effect. The surface of the metal plate has the characteristics of anti-rust, anti-oxidation, anti-scratch, anti-chemical agent and anti-smoke. In appearance, due to the special bright surface of the product itself, in order to avoid tarnishing due to friction, it is recommended to use it on a horizontal surface with less friction, or a general vertical surface. In addition, this product is recommended to be used in a dry place, or in a place where it will not be wet and the moisture is not too heavy to maintain the stability of the product. The role of the wire drawing process, the metal surface wire drawing can well cover the mechanical lines and mold clamping defects in the production.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...