What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...

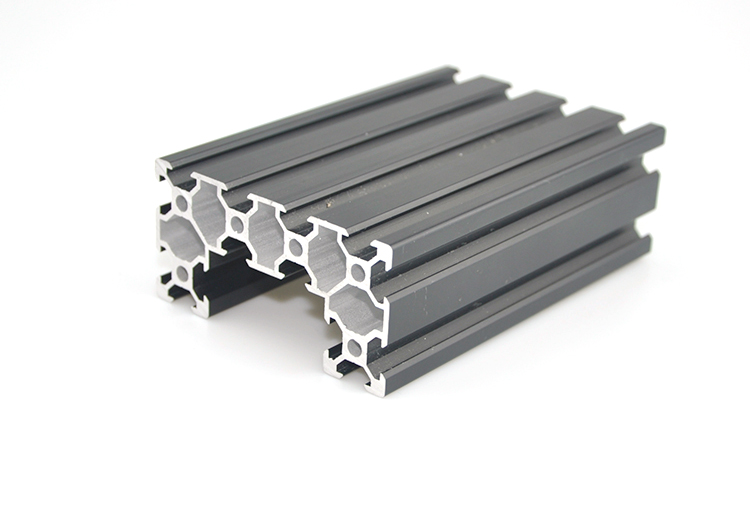

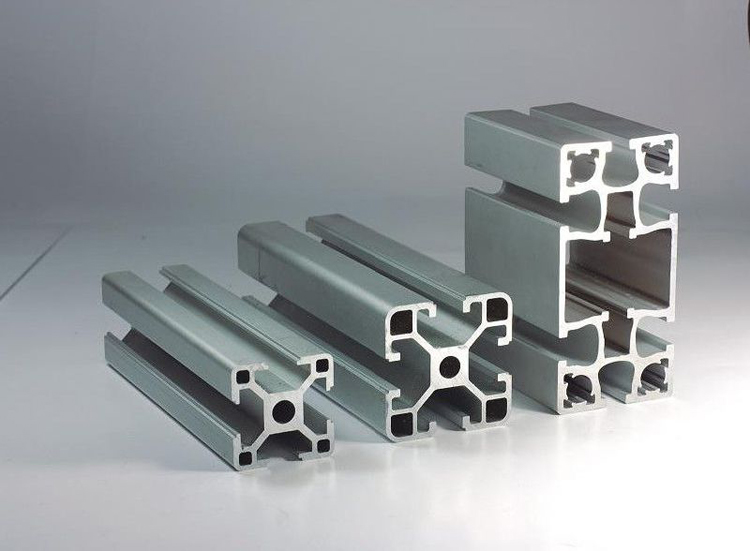

Extrusion processing occupies a special position in the aluminum alloy industrial system. This is because in recent years, with the continuous progress of science and technology and the rapid development of the national economy, the user departments have put forward new requirements for various quality indicators such as the precision, shape, surface roughness and microstructure and properties of aluminum alloy products. To ensure the supply of aluminum alloy products that meet various quality requirements to users, the use of extrusion.

Press processing technology has greater advantages and reliability than other press processing methods (such as rolling, forging, etc.). To sum up, extrusion processing has the following characteristics:

(1) During the extrusion process of industrial aluminum profiles, the extruded metal can obtain a more intense and uniform three-dimensional compressive stress state in the deformation zone than rolling and forging, and can give full play to the plasticity of the processed metal itself. Therefore, the extrusion method can be used to process those low-plastic and difficult-to-deform metals or alloys that are difficult or even impossible to process by rolling or forging. For some it must be carried out by rolling or forging.

Processed materials, such as forgings of 7A04, 7075, 5A06 and other alloys, are also commonly used to open the ingot by extrusion to improve its structure and improve its plasticity. At present, extrusion is still the most superior method by which products can be produced directly from ingots.

(2) The extrusion method can not only produce pipes, rods, shapes, and wire products with simple cross-sectional shapes, but also profiles and pipes with changing cross-sections and extremely complex shapes, such as stage-changing cross-section profiles, gradually changing cross-section profiles, and special-shaped profiles. Integral wall panel profiles of stiffeners, hollow profiles with extremely complex shapes, variable-section pipes, porous pipes, etc. Rolling or other pressures are used for such products.

Manufacturing methods are difficult, if not impossible, to produce. Special-shaped integral profiles can simplify complex technological processes such as cold forming, riveting, welding, and cutting, which have great social and economic benefits for reducing equipment investment, saving energy, improving metal utilization, and reducing the total cost of products.

(3) The extrusion processing of industrial aluminum profiles is very flexible. It is only necessary to replace extrusion tools such as molds to produce products of different shapes, specifications and varieties on one equipment. The operation of replacing extrusion tools is simple and time-consuming. Less and more efficient. This processing method is the most economical and suitable for aluminum alloy material processing and production plants with small order batches and many varieties and specifications.

(4) The precision of extruded products is higher than that of hot-rolled and forged products, and the surface quality of the products is also better. With the improvement of the technological level and the improvement of the mold quality, it is now able to produce ultra-thin, ultra-high-precision, high-quality surfaces with a wall thickness of (0.2~0.4) mm ± 0.05 mm, a surface roughness of R, and a surface roughness of 0.8-1.8um. profile. This not only greatly reduces the total workload and simplifies the subsequent steps, but also improves the comprehensive utilization rate and yield of extruded metal materials.

(5) For some aluminum alloys with extrusion effect, the longitudinal strength of the extruded products after quenching and aging is much higher than that of similar products processed by other methods. This has practical value for tapping the potential of aluminum alloy materials and meeting special application requirements.

(6) The process flow is short, the production and operation are convenient, and the overall structural parts with a larger area than hot die forging or forming rolling can be obtained in one extrusion, and the equipment investment is low, the mold cost is low, and the economic benefit is high.

(7) Aluminum alloy has good extrusion characteristics and can be processed by various extrusion processes and various die structures. In recent years, due to the continuous improvement and development of the planar split-flow composite die, the production of complex hollow aluminum products by welding and extrusion has been widely used and promoted.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...