What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

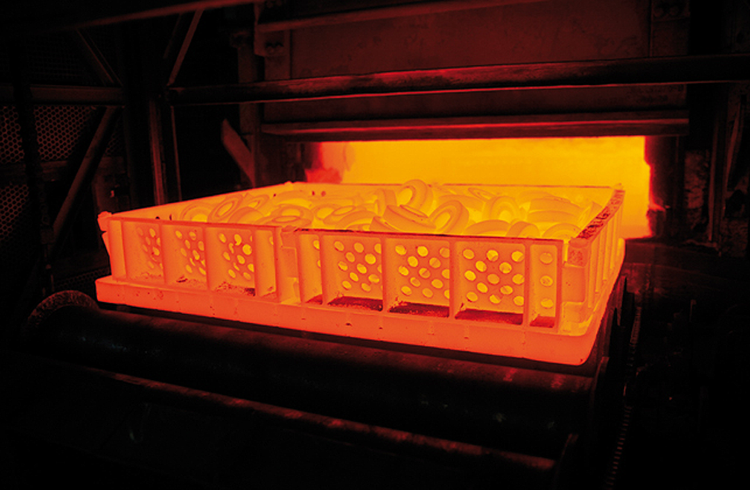

What is the difference between 201 st...Most of the heat treatment of steel needs to be heated to obtain austenite, and then cooled at different speeds to transform the austenite into different structures to obtain different properties of the steel. Therefore, to master the law of heat treatment, we must first study the changes of steel during heating.

It can be seen from the iron-carbon phase diagram that when the steel is heated to a temperature above 727°C (the PSK line of the state diagram, also known as the A1 temperature), pearlite transforms into austenite. This heating rate is very slow, and the actual heating rate of heat treatment is higher than this slow heating rate. The actual transformation temperature of pearlite to austenite is higher than A1, and the actual transformation temperature is defined as Ac1. Ac1 is higher than A1, indicating that there is thermal hysteresis, the faster the heating rate, the higher the Ac1, and the shorter the time to complete the transformation from pearlite to austenite.

The third stage: the dissolution of residual cementite. Since the rate of ferrite transforming into austenite is much higher than the dissolution rate of cementite, there is still a lot of undissolved "residual cementite" after the complete transformation of ferrite. All carbon bodies are dissolved.

The fourth stage: homogenization of the austenite composition. Even if the cementite is completely dissolved, the composition of the austenite is still uneven, the carbon content of austenite formed in the original ferrite region is low, and the carbon content of austenite formed in the original cementite region is high It needs to be kept for a sufficient time to allow the carbon atoms to fully diffuse, and the austenite composition may be uniform.

The above analysis shows that there must be two necessary and sufficient conditions for the transformation of pearlite into austenite and the uniform composition of austenite: one is the temperature condition, which must be heated above Ac1, and the other is the time condition, which requires sufficient temperature above Ac1. time. Under the condition of a certain heating rate, the higher the temperature exceeding Ac1, the shorter the time required for the formation of austenite and the homogenization of the composition; under the condition of a certain temperature (higher than Ac1), the longer the holding time, the longer the austenite composition more evenly.

It should also be seen that the change of austenite grains from small size to large size is a spontaneous process. At a certain heating temperature above Ac1, too long a holding time will lead to the merger of austenite grains and a larger size. In contrast, for the same heating time, the increasing tendency of austenite grain size caused by high heating temperature is significantly greater than that of austenite grain growth at low heating temperature. The austenite grain size is too large (or too coarse), which often leads to the reduction of the strength of the steel after heat treatment. In engineering, it is often desirable to obtain fine and uniform austenite grains. The lowest possible austenitization temperature is selected under the condition of uniform composition; the second way is to rapidly heat to a higher temperature, and then short-term heat preservation makes the formed austenite too late to grow and cool to obtain fine grains.

In engineering, the size of austenite grains is defined as grain size, and is divided into 8 grades, of which grades 1 to 4 are coarse grains, grades 5 and above are fine grains, and grades over 8 are ultra-fine grains.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...