What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

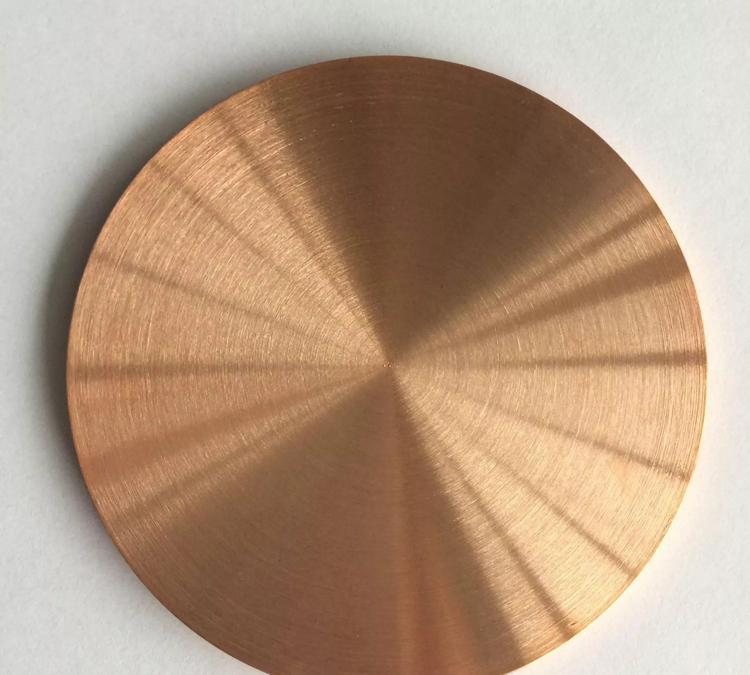

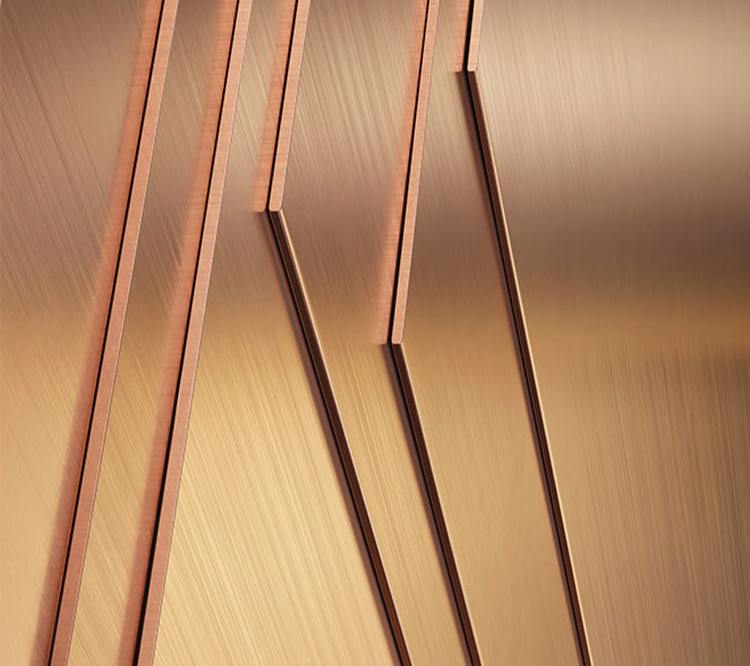

What is the difference between 201 st...Not all metals are cold. If there is any metal that can be called warm, it is "copper". Copper is a magical material. The material has a high density and a heavy texture, giving people a stable and steady feeling; the surface hardness is high, the texture is firm, giving people a strong and durable feeling; the color is golden to purple and warm, and the texture is delicate and soft, giving people a strong and durable feeling. The warm and friendly feeling and the appearance texture that is very similar to gold make copper naturally have the temperament of precious metal. As a metal material, copper is not only not sharp and cold, but a material with excellent affinity.

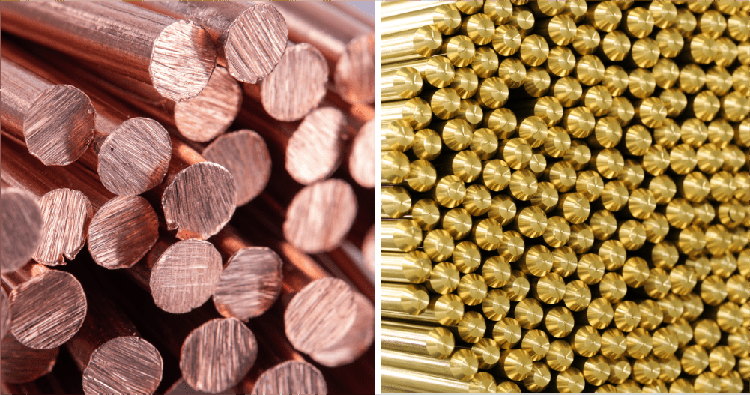

Copper is divided into pure copper and alloy copper. Different grades can be selected in response to different needs in product design. Commonly used copper materials include pure copper (red copper), brass, bronze, phosphor bronze and cupronickel.

1)The pure copper content is 99.5~99.95%. It is a soft metal, purple red.

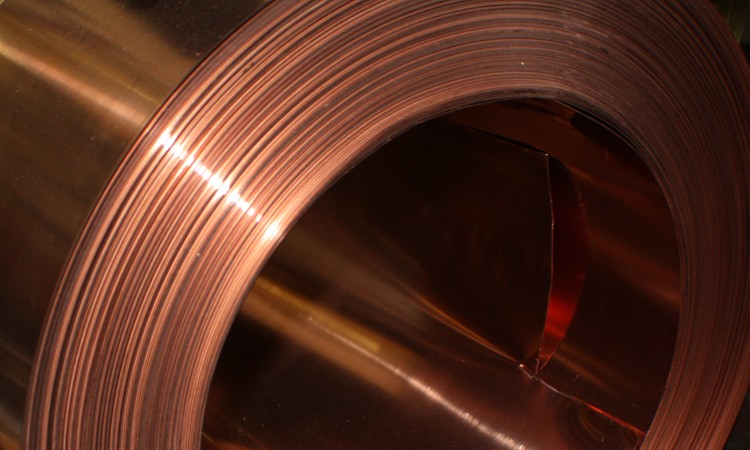

2)Good ductility, extremely high plasticity. High thermal and electrical conductivity (second only to silver). High corrosion resistance (seawater, atmosphere), good weldability, no magnetic permeability.

3)Can be recycled multiple times without compromising its mechanical properties.

4)Melting point (elemental): 1083℃

5)Boiling point (elemental): 2562℃

6)Density: 8.969 g/cm3

7)Hardness: 3 (Mohs) 35-45 (Brinell HB)

8)Thermal conductivity: 401 W/m.K

9)Ordinary copper grades: T1 T2 T3 T4 ( 50 yuan / kg )

10)Oxygen-free copper: TU1, TU2

11)Deoxidized copper: TPU

It has high electrical conductivity and is mostly found in conductive products such as wires and cables. Due to its high thermal conductivity, it can be used for industrial radiators. The appearance is high in color and luster, and is often used in jewelry and daily necessities. Its unique appearance and texture are also widely used in electronic product design.

Brass is an alloy of copper and zinc with a yellowish color. It has excellent mechanical properties and strong wear resistance. When the zinc content is less than 35%, zinc can dissolve in copper to form single-phase a, called single-phase brass, with good plasticity and suitable for cold and hot processing.

When the zinc content is 36%~46%, there is a single phase and a β solid solution based on copper and zinc, which is called dual-phase brass. The β phase reduces the plasticity of brass and increases the tensile strength, which is only suitable for Hot pressure processing.

When the zinc content is more than 46%, the alloy will be too hard and brittle, and lose its practical value.

Brass grades are represented by "H + number", H represents brass, and the number represents the mass fraction of copper. Such as our commonly used environmentally friendly copper H59, H62 copper.

H90, H80 belong to single-phase brass, golden yellow, commonly used for plating, decorations, medals and so on. H68 and H59 belong to duplex brass, which are widely used in structural parts of electrical appliances, such as bolts, nuts, washers, etc.

A multi-component alloy composed of other alloying elements added to ordinary brass is called special brass. Commonly added elements are lead, tin, aluminum, etc., which can be called lead brass, tin brass, and aluminum brass accordingly. The purpose of adding alloying elements. The main purpose is to improve the tensile strength and improve the processability.

Special brass grade: It is expressed as "H + main addition element symbol (except zinc) + copper mass fraction + main addition element mass fraction + other element mass fraction". Such as: HPb59-1 means that the mass fraction of copper is 59%, the mass fraction of the main element lead is 1%, and the balance is lead brass with zinc.

After a long time of use, the surface of brass products will gradually oxidize, and then there will be a quaint tone with a strong charm, which makes people nostalgic. The creative team from Shanghai, Liubai Innovation, has launched a series of brass USB flash drives, which combine the ancient material of brass with modern technology. This set of brass U-disks called "Crescent Moon Series" consists of four styles. Brass U disk has the bright luster of brass, thick and heavy, the color and texture will change after long-term use, and it will glow with a unique brilliance. Brass also gradually reveals its unique charm.

The alloy of copper and tin/lead is called bronze, which is golden yellow in itself, and named after the blue color after a long time. In ancient times, it was a commonly used alloy. Bronze has high hardness, low melting point, corrosion resistance, wear resistance, excellent castability and excellent mechanical properties. Suitable for casting.

It is generally used in the manufacture of precision bearings, high-pressure bearings, mechanical parts on ships that are resistant to seawater corrosion, and various plates, pipes, bars, etc. Bronze also has an anomalous property - "thermal shrinkage and cold expansion", which is used to cast statues, and expands after cooling, which can make the eyes clearer.

Bronze has good castability, wear resistance and chemical stability.

Melting point (elemental): 800℃

The alloy of copper, tin and phosphorus (containing 2 to 8% tin, 0.1 to 0.4% phosphorus, and the remainder is copper), hard and can be used for springs.

Mainly used as wear parts and elastic elements. Especially for spring shrapnel that require high performance elasticity.

Computer connectors, mobile phone connectors, high-tech industry connectors, electronic and electrical springs, switches, slots, buttons, vibrating sheets and terminals for electronic products.

Cupronickel is an alloy of copper and nickel (generally, nickel metal accounts for 25% of the alloy), with a color similar to silver, silver-white, and not easy to rust.

Commonly used in the manufacture of coins, appliances, meters and decorations. Because silver is very similar, unscrupulous merchants will pretend to be silver products with white copper.

Commonly used cupronickel are B30, B10, zinc cupronickel and aluminum cupronickel.

B30 has the strongest corrosion resistance, but it is more expensive.

The performance of aluminum cupronickel is close to that of B30, the price is low, and it can be used as a substitute for B30.

Zinc white copper has been produced and used in China in the 15th century, and is called "Chinese silver". The so-called nickel silver or German silver also belongs to zinc white copper.

Zinc can be dissolved in a large amount of copper and nickel, resulting in solid solution strengthening and corrosion resistance.

After adding lead, zinc white copper can be easily cut into various precision parts, and has corrosion resistance, high strength and low price. Aluminum in aluminum cupronickel can significantly improve the strength and corrosion resistance of the alloy.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...