What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

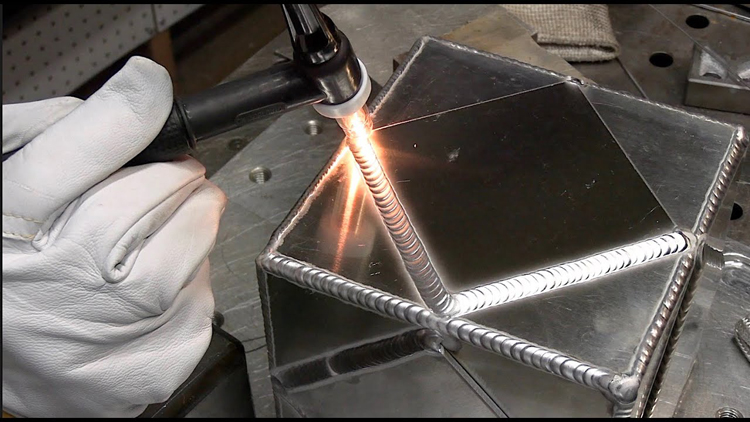

What is the difference between 201 st...Nickel-based and iron-nickel-based alloys can generally be welded using the same welding methods as austenitic stainless steels. The most commonly used arc tungsten arc welding, MIG welding and manual arc welding are discussed here. Regardless of the welding method, the surface of the welding area must be thoroughly cleaned before welding. Nickel-based and iron-nickel-based alloys are more sensitive to the hazards of contaminants. The base metal should be welded in solution state as far as possible.

Tungsten inert gas welding (TIG welding) is the most widely used, and it is suitable for almost any kind of nickel-based and iron-nickel-based alloys that can be welded, especially for thin parts and small-section components. TIG welding is divided into manual welding. TIG welding and automatic TIG welding. The most commonly used protective gas is argon, which has low cost, high density and good protection effect. Adding 5% hydrogen to argon has a reducing effect. Generally, it is only used for the first pass and single pass welding. The remaining passes of multi-layer welding may produce pores. Helium shielded welding is rarely used, but it has the following characteristics. Helium has high thermal conductivity and relatively large heat input to the molten pool, which can improve the welding speed and reduce the possibility of porosity. However, when the current is less than 60A in helium arc welding, the arc does not Stablize.

TIG welding generally uses DC positive polarity, using high-frequency arc ignition and current-decaying arc-finishing technology. Under the condition of ensuring the penetration, a small welding line energy should be used, and the interlayer temperature should be controlled during multi-layer welding. When welding precipitation-strengthened alloys and alloys with high thermal crack sensitivity, more attention should be paid to controlling the interlayer temperature. The arc length should be as short as possible, and the welding torch may not swing when welding thin parts, but during multi-layer welding of thick plates, in order to fully fuse the deposited metal with the base metal and the previous weld, the welding torch can still swing appropriately.

In order to ensure complete penetration of single-sided welding, a copper liner with a concave groove is required, and the reverse side is protected by protective gas. In order to strengthen the protection effect of the welding area, a drag cover for auxiliary input of protective gas can also be added to the rear side of the welding tip.

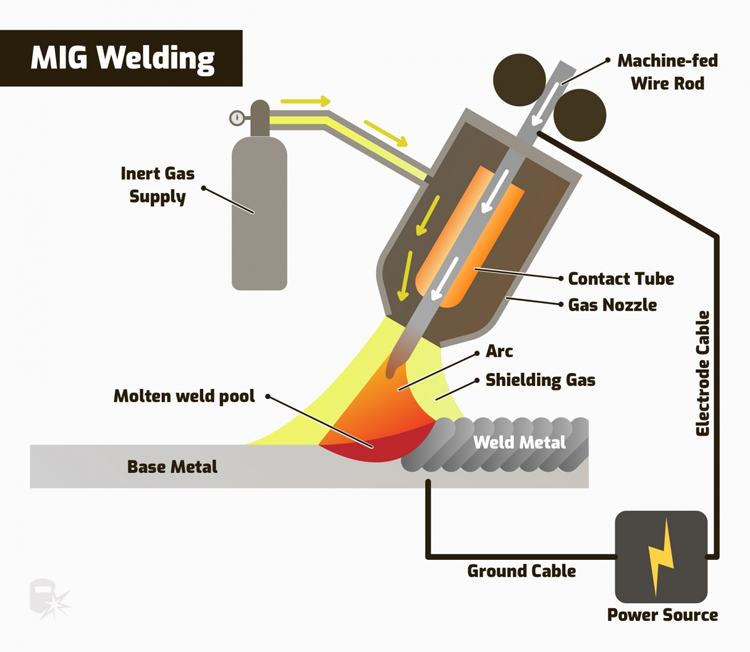

MIG welding (MIG welding) can be used for the welding of nickel-based and iron-nickel-based alloys solid solution strengthened alloys. It is generally not used for the welding of alloys with high content of precipitation strengthening elements and casting alloys, and the heat input of MIG welding is large. , high production efficiency, often used for thicker components. The shielding gas is commonly argon, and argon + helium mixed gas is also used. In order to prevent or reduce splashes and improve the fluidity of liquid metal, it is recommended to use argon + helium mixed gas protection. At the same time, the transition form of the filler wire to the molten pool has a great relationship with the choice of gas. MIG welding with droplet transfer and short-circuit transfer has large metal spatter and poor arc stability.

It is better to use pure argon as the shielding gas for MIG welding with droplet transfer, and it is better to use argon deca helium as shielding gas for MIG welding with short-circuit transition. MIG welding of jet transition, due to the large current, will cause large welding stress, which is easy to cause welding cracks. It is better to use pure argon as the protective gas. Pulse jet transition MIG welding is often used, it has good arc stability and less heat input, and argon + 15% nitrogen gas mixture is recommended as the shielding gas. MIGIGHT generally adopts DC reverse polarity. In the groove design, the thickness of the blunt edge of the groove should be determined according to the selected transition form. The arc length should be appropriate, too long will affect the protection effect of inert gas, too short will cause splashing. Pay attention to the protection of the back when welding on one side and forming on both sides.

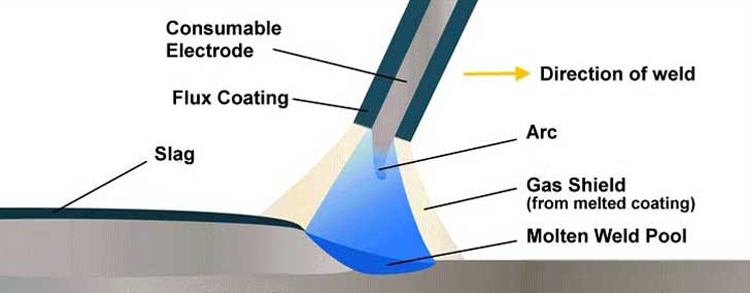

Manual arc welding mainly uses solid solution strengthened alloys of nickel-based and iron-nickel-based alloys. Because the electrode contains a lot of alloying elements, and it is required to prevent hot cracks, the coating type of nickel-based and iron-nickel-based alloy electrodes is generally alkaline coating, and DC reverse polarity is used. In order to prevent the burning of alloying elements and control the amount of heat input, it is required to use small specifications as much as possible during welding. Compared with stainless steel electrodes of the same specification, the current can be reduced by 20%~30%.

Due to the poor fluidity of liquid metal, in order to prevent Defects such as lack of fusion and porosity generally require proper swing during the welding process, but not too large. When re-starting the arc at the weld interface, the reverse arc-starting technology should be used to facilitate the smooth welding of the adjustment interface and to suppress the occurrence of porosity. Reverse arc ending is used to fill the crater to prevent crater cracks, and the crater should be polished if necessary.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...