What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...Spring steel is divided into non-alloy spring steel (ie carbon spring steel) and alloy spring steel.

Alloy spring steel: generally contains 0.45%~0.70% carbon and a certain amount of alloying elements such as Si, Mn, Cr, V, W and B. The addition of alloying elements improves the anti-relaxation properties of spring steel and improves the toughness of steel.

Carbon spring steel: steel contains 0.60%~0.90% carbon and 0.3%~1.20% manganese, no other alloying elements are added, and the cost is low.Spring steel for automobiles and motorcycles can be divided into spring steel for suspension and spring steel for valve springs.

According to GB/T13304 standard, spring steel is divided into non-alloy spring steel (carbon spring steel) and alloy spring steel according to its chemical composition.

1) Carbon spring steel

The carbon content (mass fraction) of carbon spring steel is generally 0.62%~0.90%. According to its manganese content, it is divided into general manganese content (mass fraction) (0, 50%~0, 80%) such as 65, 70, 85 and higher manganese content (mass fraction) (0, 90~1, 20%) , such as 65Mn two types.

2) Alloy spring steel

Alloy spring steel is based on carbon steel, by appropriately adding one or several alloying elements to improve the mechanical properties, hardenability and other properties of the steel to meet the properties required for the manufacture of various springs.

The basic composition series of alloy spring steel are: silicon-manganese spring steel, silicon-chromium spring steel, chromium-manganese spring steel, chromium-vanadium spring steel, tungsten-chromium-vanadium spring steel, etc. On the basis of these series, some grades have added alloying elements such as molybdenum, vanadium or boron in order to improve their performance in some aspects.

In addition, some grades are also selected as spring steel from other steels, such as high-quality carbon structural steel, carbon tool steel, high-speed tool steel, and stainless steel.

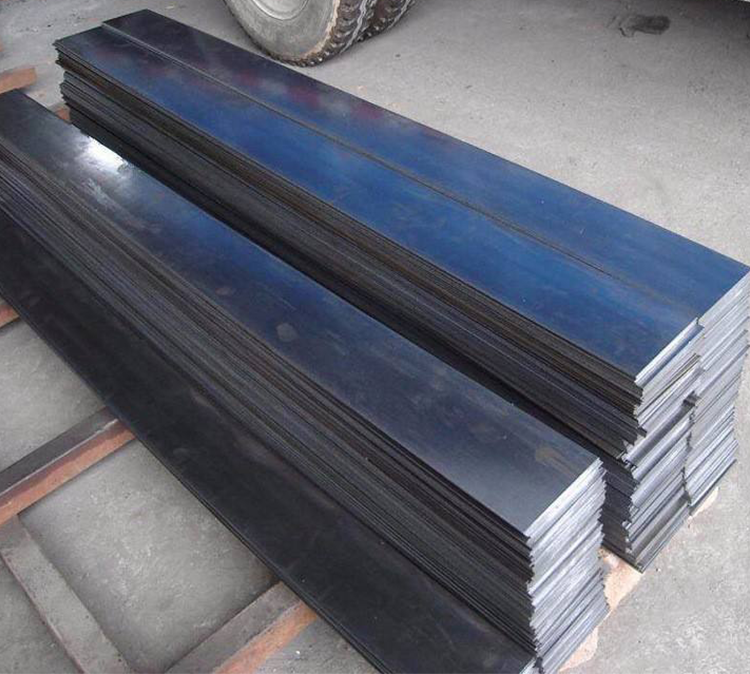

1) Hot-rolled (forged) steel includes hot-rolled round steel, square steel, flat steel, steel plate, forged round steel and square steel.

2) Cold-drawn (rolled) steel includes steel wire, steel strip, and cold-drawn material (cold-drawn round steel).

1) Hot rolled (forged) steel

A. Delivered in hot-rolled (forged) condition Steel is hot-formed into springs, then quenched and tempered.

B. Delivered in Annealed Condition Steel is cold formed into springs, then quenched and tempered.

All of the above shall comply with the provisions of the corresponding hardness in the delivery state.

2) Cold drawn (rolled) steel

A. Steel wire

① Salt-bath isothermal quenching cold-drawn steel wire (also known as Peddon-treated cold-drawn steel wire) After the steel wire is made into a spring, it only needs to be tempered at low temperature to relieve stress.

② Oil quenched and tempered steel wire After cold drawing to the required size, continuous heating, continuous oil quenching and lead tempering are performed. After the steel wire is made into a spring, it only needs to be warmed at the bottom to relieve stress.

③ Cold-drawn steel wire (ie, steel wire without quenching and tempering)

a. Delivered in cold drawn condition.

b. Delivered in annealed, normalized or tempered condition.

The steel wire delivered in the above two states needs to be quenched and tempered after being made into a spring.

B. Steel belt

① Delivery in cold-rolled state After the spring is made, it needs to be tempered at low temperature to relieve stress.

② Delivery in quenched and tempered state After the spring is made, it needs to be tempered at low temperature to relieve stress.

③ Delivered in annealed state. Quenching and tempering are required after the spring is made.

C. Cold drawn steel

Delivered in annealed condition Steel is cold formed into springs, then quenched and tempered.

In addition to the above, there are some other classification methods such as:

According to different delivery conditions, it can be divided into delivery according to chemical composition (mechanical properties) and delivery according to hardenability.

According to the working conditions of the spring, it can be divided into static load spring steel, shock load spring steel, high (low) temperature resistant spring and corrosion resistant spring steel.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...