What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

What is the difference between 201 st...Industrial aluminum profiles and architectural aluminum profiles belong to the 6063 grade aluminum profiles, so their alloy composition and alloy content are the same, so there is no difference in mechanical properties between industrial aluminum profiles and architectural aluminum profiles. Other than that, their weldability, electrical and thermal conductivity, surface treatment, corrosion resistance and machinability are all the same, so what's the difference?

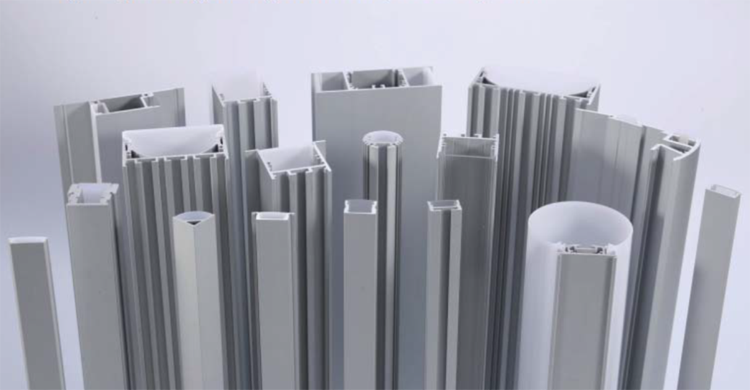

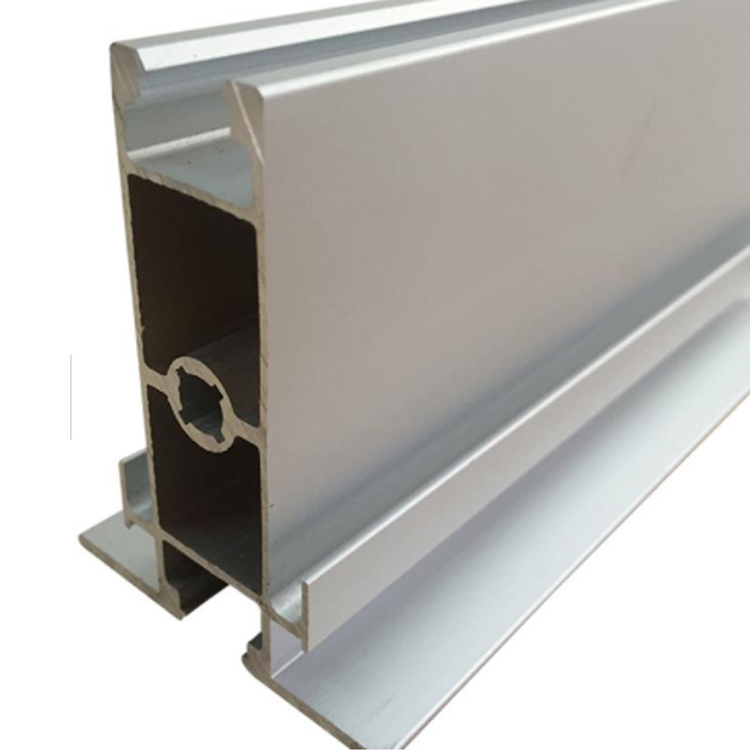

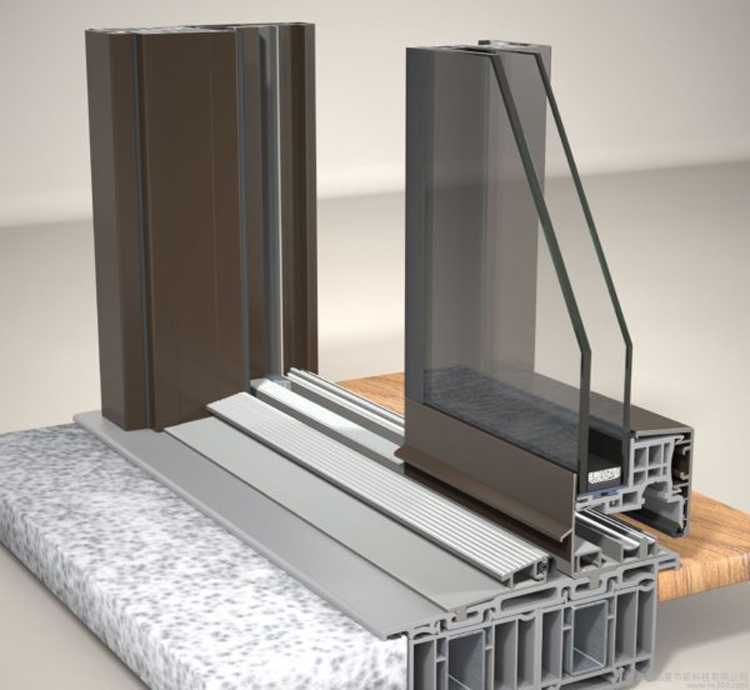

Industrial aluminum profiles are mostly symmetrical structures and relatively square. Most of the architectural aluminum profiles have asymmetric cross-sections, and the curvature is relatively large, and some have relatively large cantilevers. However, industrial aluminum profiles have more cavities than architectural aluminum profiles, and most of them are round holes.

In general, the wall thickness of industrial aluminum profiles is larger than that of architectural aluminum profiles. Because the load-bearing of the door, window and curtain wall profiles is not so high, it is more for decoration, so the wall thickness is relatively thin. Most industrial aluminum profiles are used on equipment frames and brackets, so they have higher load-bearing requirements and thicker wall thicknesses.

The surface of industrial aluminum profiles generally only needs anodizing treatment, and at most one sandblasting process is added to make a matte effect. There are many surface treatment methods for architectural aluminum profiles, such as spraying, electrophoresis, and wood grain transfer. Because architectural aluminum profiles pay more attention to decoration, the colors are more abundant. And industrial aluminum profiles pay attention to atmosphere and cleanliness, generally only need natural color oxidation treatment, and a few need black oxidation.

The geometric tolerance requirements of industrial aluminum profiles are higher than those of architectural aluminum profiles, and the surface quality requirements of the substrate are higher. Because of the transparent oxide film formed by the anodization of industrial aluminum profiles, if there are any defects on the surface of the substrate, it will be clear at a glance.

(1) Industrial aluminum profiles are relatively more regular in shape, and many industrial aluminum profiles are symmetrical in section. The architectural aluminum profiles are mostly irregular. Moreover, industrial aluminum profiles generally play a load-bearing role and are relatively thick. Building doors and windows aluminum profiles, decorative profiles are relatively thin.

(2) The surface of industrial aluminum profiles is generally anodized, and the colleagues that show the true color of aluminum are more wear-resistant and corrosion-resistant. There are many surface treatment methods for other aluminum profiles, such as spraying, electrophoresis, wood grain transfer and so on.

(3) There are many cavities in industrial aluminum profiles. The cavity design on industrial aluminum profiles is based on mechanics, and the weight of the aluminum profiles can be reduced without affecting the load-bearing. And some cavities are reserved mounting holes. Other aluminum profiles have relatively thin walls and do not require many mounting holes, so there are fewer cavities.

(4) Many industrial aluminum profiles require deep processing. Due to the installation on the equipment, many industrial aluminum profiles require deep processing such as drilling, tapping, and slot milling, while other aluminum profiles rarely require deep processing.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...