What is the difference between 201 stainless steel and 304 stainless steel?

What is the difference between 201 st...

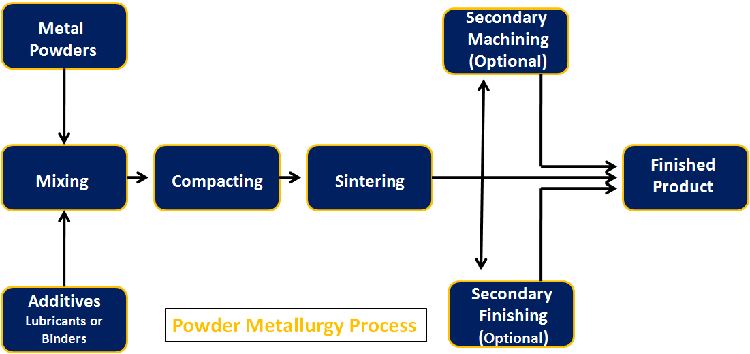

What is the difference between 201 st...Powder metallurgy materials are more and more widely used in modern industry. In the application of high-density and high-precision complex parts replacing forgings, rapid development has also been achieved with the continuous progress of powder metallurgy technology. However, due to the difference in the subsequent treatment process, there are still some defects in its physical and mechanical properties. This paper briefly describes and analyzes the heat treatment process of powder metallurgy materials, analyzes its influencing factors, and proposes strategies to improve the process.

Powder metallurgy materials are more and more widely used in modern industry, especially in the application of automobile industry, daily necessities, mechanical equipment, etc., powder metallurgy materials have occupied a large proportion. They have obvious advantages in replacing cast iron materials with low density, low hardness and strength, and are gradually popularized in the application of precision and complex parts with high hardness, high precision and strength, thanks to the rapid development of powder metallurgy technology. The heat treatment process of fully dense steel has been successful, but the heat treatment of powder metallurgy materials still has some defects due to the difference in physical properties of powder metallurgy materials and the difference in heat treatment process. In the technical research of powder metallurgy materials in various casting and smelting enterprises, heat treatment and subsequent treatment processes such as hot forging, powder injection molding, hot isostatic pressing, liquid phase sintering, combined sintering, etc. In the improvement, certain effects have been achieved, and the strength and wear resistance of powder metallurgy materials have been improved, which will greatly expand the application range of powder metallurgy.

The heat treatment of powder metallurgy materials should be determined according to their chemical composition and grain size. The existence of pores is an important factor. During the process of pressing and sintering powder metallurgy materials, the pores formed throughout the whole part, and the existence of pores affects the way of heat treatment. and effects.

There are several forms of heat treatment for powder metallurgy materials: quenching, chemical heat treatment, steam treatment and special heat treatment:

Due to the existence of pores, the heat transfer rate of powder metallurgy materials is lower than that of dense materials, so the hardenability is relatively poor during quenching. In addition, during quenching, the sintering density of the powder material is proportional to the thermal conductivity of the material; because of the difference between the sintering process and the dense material, the internal structure uniformity of the powder metallurgy material is better than that of the dense material, but there are smaller microscopic regions. Inhomogeneity, therefore, the full austenitization time is 50% longer than the corresponding forging, and the full austenitization temperature will be higher and the time will be longer when alloying elements are added.

In the heat treatment of powder metallurgy materials, in order to improve the hardenability, some alloying elements such as nickel, molybdenum, manganese, chromium, vanadium, etc. are usually added. When it dissolves in austenite, it will increase the stability of supercooled austenite, ensure the austenite transformation during quenching, increase the surface hardness of the material after quenching, and also increase the quenching depth. In addition, powder metallurgy materials must be tempered after quenching. The temperature control of tempering treatment has a great influence on the performance of powder metallurgy materials. Therefore, the tempering temperature should be determined according to the characteristics of different materials to reduce the influence of tempering brittleness. General materials can be tempered in air or oil at 175-250℃ for 0.5-1.0h.

2CO≒[C]+CO2 (exothermic reaction)

CH4≒[C]+2H2 (endothermic reaction)

After the carbon is decomposed, it is absorbed by the metal surface and gradually diffuses into the interior. After a sufficient carbon concentration is obtained on the surface of the material, quenching and tempering are carried out, which will improve the surface hardness and quenching depth of the powder metallurgy material. Due to the existence of pores in powder metallurgy materials, activated carbon atoms penetrate into the interior from the surface to complete the process of chemical heat treatment. However, the higher the material density, the weaker the porosity effect and the less obvious the effect of chemical heat treatment. Therefore, a reducing atmosphere with a higher carbon potential should be used for protection. According to the pore characteristics of powder metallurgy materials, the heating and cooling rates are lower than those of dense materials, so the holding time should be prolonged and the heating temperature should be increased during heating.

Chemical heat treatment of powder metallurgy materials includes several forms such as carburizing, nitriding, sulphurizing and multi-component co-infiltration. In chemical heat treatment, the hardening depth is mainly related to the density of the material. Therefore, corresponding measures can be taken in the heat treatment process, such as: when carburizing, when the material density is greater than 7g/cm3, the time is appropriately extended. The wear resistance of the material can be improved by chemical heat treatment. The non-uniform austenite carburizing process of the powder metallurgy material can make the carbon content of the surface of the treated material reach more than 2%, and the carbides are evenly distributed on the surface of the carburized layer. , can well improve the hardness and wear resistance.

Steam treatment is to oxidize the surface of the material by heating steam to form an oxide film on the surface of the material, thereby improving the performance of the powder metallurgy material. Especially for the anti-corrosion of the surface of powder metallurgy materials, its validity period is more effective than that of bluing treatment, and the hardness and wear resistance of the treated materials are significantly increased.

Special heat treatment process is the product of scientific and technological development in recent years, including induction heating quenching, laser surface hardening, etc. Induction heating and quenching is under the influence of high-frequency electromagnetic induction eddy current, the heating temperature increases rapidly, and has a significant effect on the increase of surface hardness, but it is prone to soft spots. Generally, intermittent heating method can be used to prolong the austenitization time; laser surface hardening The process uses the laser as the heat source to rapidly heat up and cool the metal surface, so that the substructure inside the austenite grain cannot recover and recrystallize to obtain an ultra-fine structure.

What is the difference between 201 st...

What is the difference between 201 st... Why is 316 stainless steel better tha...

Why is 316 stainless steel better tha... 400 series stainless steel science

40...

400 series stainless steel science

40... How to distinguish the processing tec...

How to distinguish the processing tec... Non-standard design materials of bras...

Non-standard design materials of bras... What type of titanium alloy does Tc4 ...

What type of titanium alloy does Tc4 ...